Foreword: Aluminum is an amphoteric metal that reacts with acids and bases. The response is as follows:

Therefore, workpieces mainly made of aluminum alloy are easily damaged in acidic or alkaline cleaning agents. Similarly, in the process of aluminum alloy processing, regardless of boring, grinding, cutting, if the use of poor quality Taikoo oil or cutting oil causes the aluminum alloy to come into contact with acid or alkali or peroxide formed due to high temperature, it should be cleaned after cleaning. After that, there will be slight corrosion marks on the surface. These traces, if very shallow, can be wiped off with a chemical such as silicon dioxide film cleaner SMC03 (pH 7.0). As shown below.

There are uneven deep and light marks on the surface before wiping

after wiping

If the trace is very deep, it needs to be removed by grinding, vibrating bead beating, sandblasting and other methods.

To avoid the corrosion of aluminum workpieces caused by the processing oil used in boring and grinding, the processing oil should be selected carefully first. You can consider using our company Xiwei TM water-based metal processing oil.

For the grinding surface that requires high precision, it can be covered with UV hardened resin, and then sandblasting, vibration grinding, etc. After processing, remove the hardened resin with a special neutral paint stripper for aluminum alloys.

-

before cleaning

The size of this aluminum die casting is about: L46*W42*H10(cm), and the surface is covered with traces of different shades of color.

-

Photomicrographs show that these traces of different shades are not only different in shades of color, but also uneven on the surface. Therefore, if only the aluminum alloy bleaching agent ABA01 is used for reductive bleaching, the blackened part can only be whitened, and the difference in color depth is less significant, and the unevenness of the surface cannot be improved.

-

Then zoom in and observe: these traces are not only different in color, but also uneven on the surface.

-

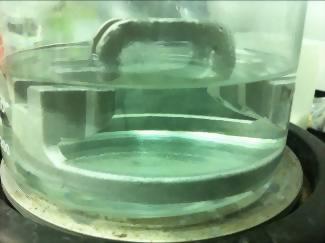

Therefore, in order to make the surface luster uniform, proper grinding or sandblasting is required. In the picture below, the surface is rubbed with a green vegetable cloth dipped in ABA01, a special bleaching agent for aluminum alloys.

-

After rubbing, the surface gloss becomes more uniform.

Shoot from another angle.

-

Suggestions and discussions:

7.1 It is recommended to replace the cutting oil to avoid corrosion of the aluminum alloy surface caused by the processing oil.

7.2 Grind the corroded surface. If you use pickle cloth to scrub, you should grind it with the style containing emery (green, black, deep red). In addition, there are many types of pickle cloth. If you don’t like fine lines on the surface of the aluminum workpiece, you should choose the pickle with finer emery cloth. Vibratory grinding with stainless steel beads is also available as an option.

7.3 After the surface is evenly ground, it can be soaked in aluminum alloy special bleach ABA01 for reduction bleaching to make the aluminum workpiece more shiny.