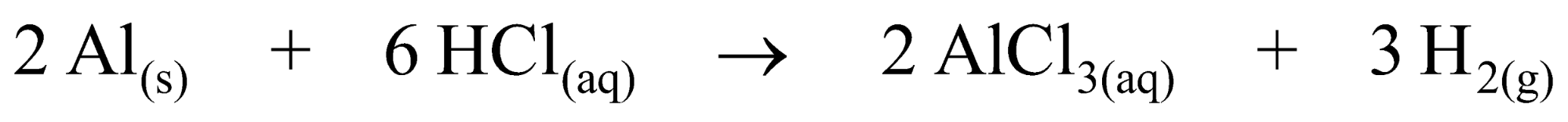

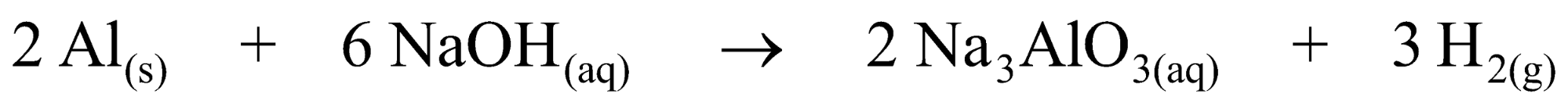

Foreword: Aluminum is an amphoteric metal that reacts with acids and bases. Therefore, the chariot engine mainly made of aluminum alloy is easily damaged in acidic or alkaline cleaning agents. The response is as follows:

If the chariot engine comes into contact with acidic or alkaline cleaners, even if it is cleaned, there will be slight corrosion marks on the surface. Although these tiny gaps are not easy to observe with the naked eye, when the piston moves at high speed in the cylinder, it will appear. Enlarging these gaps causes vibration and rough operation. Microscopic observation reveals slight changes in the surface of aluminum alloys after cleaning with acidic or alkaline cleaners.

Therefore, this test refers to the use of neutral detergents AHLR03 and AHLR03-D as test agents.

-

before cleaning

-

Dip the agent AHLR03 with a barbecue brush, and brush gently at room temperature.

-

After scrubbing. It is found that AHLR03 can effectively remove the sludge attached to the surface of the tank engine.

-

Then use AHLR03-D to gently brush the other half of the unwashed tank engine at room temperature.

-

After scrubbing. It is found that AHLR0-D can more effectively remove the oil sludge attached to the surface of the tank engine.

-

Suggestions and discussions:

6.1 AHLR03 and AHLR03-D confirm that it is effective in cleaning the sludge attached to the surface of the tank engine; and it does not damage the main body of the tank engine.

6.2 The test is to clean it with a barbecue brush at room temperature. If it can be heated and sprayed with high pressure, the cleaning effect will be improved. If it can be pre-soaked, after the sludge is decomposed and loosened, and then sprayed, the effect will be better.

6.3 AHLR03 and AHLR03-D are 100% biodegradable, with low toxicity, high boiling point (>255°C), high flash point (>105°C), and low volatilization rate: 0.01 (butyl acetate = 1). It has a mild smell when used, reduces VOC and the odor of the unit used is tolerable.

6.4 AHLR03 and AHLR03-D use low-foaming surfactants, which are suitable for use in fully automatic high-pressure spray washing machines. During use, there will be no bubbles that will cause the machine to misjudge the liquid level of the chemical tank or contact the electronic parts to cause a short circuit.