-

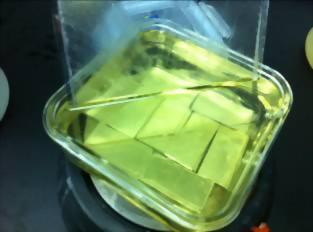

Before cleaning (applied to Sensor deglue)

-

Add AHLR03 and soak at 70degC for 1hr.

-

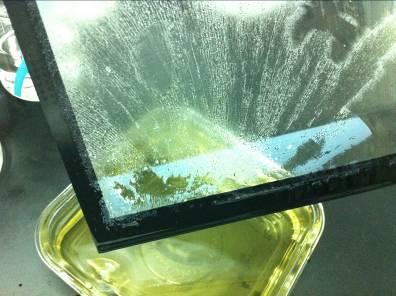

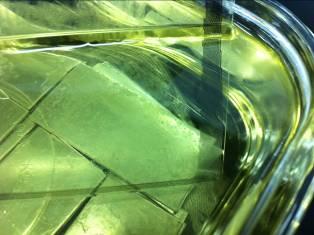

take out. It is found that the optical liquid glue soaked in AHLR03 has turned white and started to rot. Can be wiped off with a lint-free cloth.

-

Observing the molybdenum aluminum molybdenum wire with a microscope will not hurt at all.

-

Suggestions and discussions:

5.1 AHLR03 confirms that the optical liquid glue stripping of YD's 10.1"Touch panel CG sample is effective.

5.2 Under heating at 70degC, it is still not easy to peel off the optical liquid glue. The soaking time should be extended to make it easier to wipe off the glue. Or scrape off the thick glue before soaking to reduce the soaking time.

5.3 The surfactant used in AHLR03 is biodegradable, has low toxicity, high boiling point (>255°C), high flash point (>105°C), and low volatilization rate: 0.01 (butyl acetate = 1). It has a slight smell when used, and can replace natural glue removers, reduce VOC and odor tolerance of the user unit.