-

The bottom layer of the solar module is used to protect the solar chip from the external environment, and reduce the short-circuit degradation of the chip module due to ultraviolet light, humidity, corrosion, temperature changes, physical impact, electric shock, etc. The encapsulation film layer is called solar energy Backsheets.

-

Based on the actual experience in the past, it was found that the incorrect selection of the backsheet material will seriously affect the life of the solar module and the power generation efficiency. Therefore, according to the information provided by DuPont, most of the major solar module manufacturers in the world today use DuPont's Tedlar® PVF film as the material for the solar backsheet.

The picture below shows the damage situation of the solar panel using PVDF material as the solar backplane.

下圖為採用PET材料作為太陽能背板的太陽能板損壞情形。

The picture below is the information provided by DuPont, claiming that DuPont Tedlar® PVF film is used as the material of the solar backsheet, and such solar panels can still be used for more than 20 years.

-

As DuPont claims, Tedlar® PVF film has become the backsheet material chosen by major solar module manufacturers in the world, which is not a bad thing. This kind of situation can greatly reduce the recycling process due to different materials and structures when the solar module is damaged and recycled in the future. The recycling process is too complicated and the recycling efficiency is not good.

The picture below shows that when PVDF film was used as a solar backsheet in the past, it was found that different manufacturers have different structures of PVDF film.

This can lead to difficulties in recycling.

-

If all major solar module manufacturers in the world choose DuPont Tedlar® PVF film as solar backsheets, the problem of recycling backsheets can be specialized, but it does not mean that the problem of backsheet recycling has been solved.

At present, when recycling solar modules, the outer aluminum frame and the outermost layer of glass can be easily recycled by tearing off the chip module under the glass together with the back plate, and the hard materials: aluminum frame and glass can be easily recycled.

According to the information provided by customers, the encapsulation layers above and below the solar cells are generally made of EVA. According to the thermal cracking experiment conducted by Chuo University, such materials can be effectively burned into carbon dioxide and water, and the remaining ash is mainly composed of silicon (Silicium), which is a component of solar wafers, and silver (Sliver) wires distributed in it, and trace residues carbon (about 0.17%).

However, the PVF backsheet contains fluorine, which may produce hydrofluoric acid during combustion, corrode the incinerator, and pose a threat to industrial safety. It is not recommended to use the combustion method.

Fortunately, after heating the torn EVA/Solar cells/EVA/Backsheets, it was found that the backsheet (Backsheets) can be torn off from the EVA again.

Therefore, the purpose of this experiment is to find out a method that can effectively separate and recycle Tedlar® PVF film for solar backplanes. -

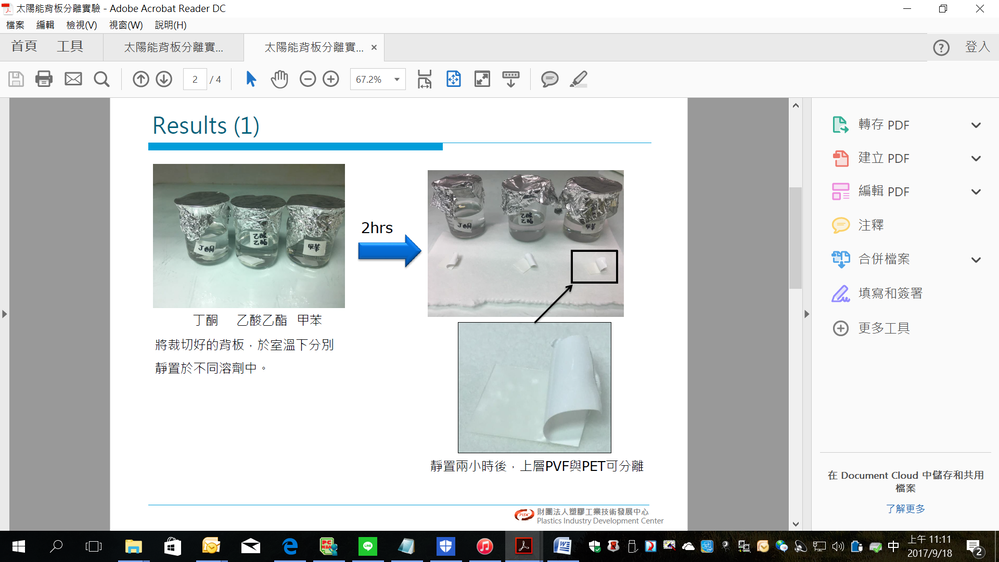

At present, according to the test report made by the Plastic Industry Technology Development Center, the solar backplane Tedlar® PVF film can be preliminarily separated by soaking in toluene, ethyl acetate, and methyl ethyl ketone.

Then, separate the PET film and PVF film under the separated Tedlar® PVF film with DMF heated to 80°C or ethyl acetate heated to 60°C.

-

However, due to toluene (flash point 4.4°C), methyl ethyl ketone (flash point -6~-2°C), ethyl acetate (flash point -4.4°C), in industrial applications, a large amount of volatile vapors will be produced (VOC), in addition to public security hazards, a large amount of volatilization also makes the solvent loss too large. The problem of easy combustion at room temperature poses a great threat to the large-scale use of recycling plants. Low-temperature flammable solvents are public hazardous substances and need to be separated and managed on a case-by-case basis. And the airtight measures to reduce volatilization, and the heating process, have more doubts about explosion.

-

Therefore, the purpose of this experiment is to find a chemical that can be mass-produced industrially, and has a high flash point (flash point>60°C, storage at room temperature without separate management), low volatility (volatility rate<0.01( BuAc: 1)), environmental protection (can be decomposed in the environment, released into the air, half-life is less than 24 hours), non-corrosive (according to GHS classification, no corrosive label is required), low toxicity (according to GHS classification, no need to skull logo). Moreover, it can effectively separate Tedlar® PVF film, and in one step, separate Tedlar® PVF film into PVF, PET, and PVF.