-

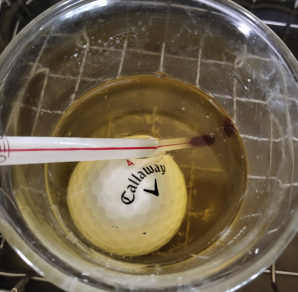

If the outer layer of the golf ball is poorly sprayed during the production process, the usual practice is to scrap it or take out the ball center to make it again. We have developed a special agent for peeling off the outer coating (ink/spray) of golf balls. The following are several golf ball products of customers. We put them into beakers respectively, and then add our cleaning agent just to submerge the ball. .

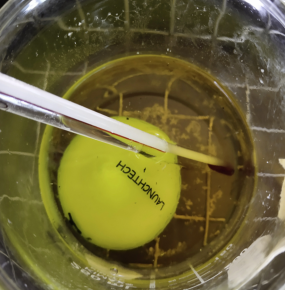

From left to right, from top to bottom, in order of 1~6 balls

-

After soaking at room temperature for 3 hours, the paint on the surface of No. 5 and No. 6 balls has softened. Wipe with a kitchen paper towel to remove the top coat and marking pattern, and then try to use the heating method to find that 45-50 ° C for 30 minutes Can also strip top coat and marking.

The picture on the left shows the ball number 5, and the picture on the right shows the ball number 6

-

Heat the remaining balls to 45-50°C. After about 60 minutes, it is found that the topcoat/marking and primer of No. 4 balls can also be removed by wiping with paper towels. The red afterimage is dye transfer. Pigment has migrated onto the primer. Continue to soak to remove the primer to remove it. If the staining is too deep, sarin and unisin can’t be destroyed and decomposed if it goes deep into sarin and unisin, because the formula can’t harm sarin and unisin, so the removal method can’t be used, only the decomposition method can be used. The dyes used on golf balls are usually "very good" because they need to be resistant to sunlight. If the dye decomposer still cannot be decomposed, it is recommended to use a PU primer of the same color with higher masking properties to spray a layer first. Then add the LOGO.

This is ball number 4

-

Keep heating at 45-50°C. After 2 hours, it is found that the top coat and marking of No. 3 ball can be removed by wiping. Continue to heat for about 3 hours, and the primer can also be removed by wiping with a little force.

The left picture shows the No. 3 ball stripping the topcoat, and the right picture shows the No. 3 ball stripping the topcoat and primer

-

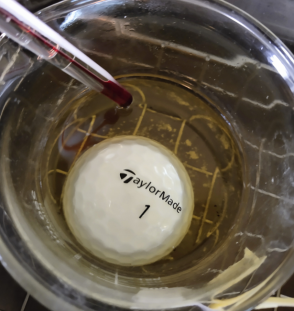

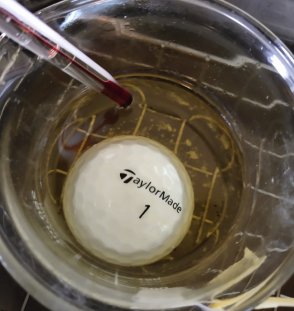

Keep heating at 45-50°C. After 4 hours, the top coat of No. 1 ball starts to become a little soft. You can remove the top coat and marking by wiping with kitchen paper towels. It may be because the top coat is relatively strong and you need to use more force to wipe it off completely. In addition to cleaning, you can extend the soaking time or increase the temperature to improve.

This is ball number 1

-

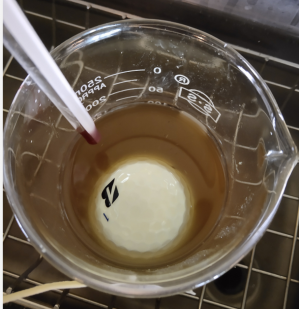

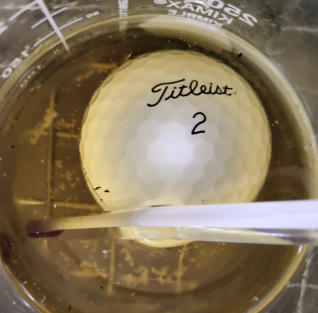

The remaining No. 2 balls are heated at 45-50°C, and after 5 hours, the topcoat/marking and primer can be wiped off together by wiping vigorously.

This is ball number 2

-

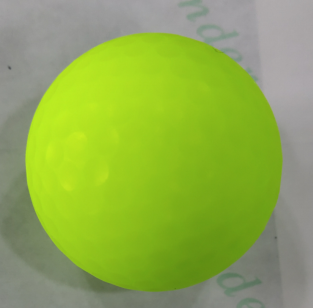

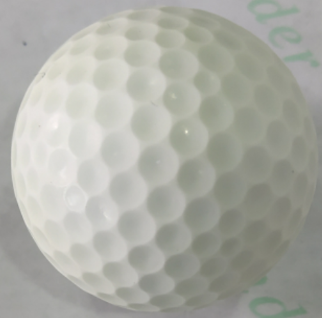

The surface of the ball that has just been stripped of the primer will turn yellow. It is presumed that some bonding groups will remain on the surface of the primer. Stripping the topcoat won't have this problem.

Before soaking in warm water at 40°C

after soaking

-

Conclusion: AHLR03-D2Plus4 Hardened Ink Cleaner can remove the hardened primer, marking and topcoat on the surface of golf balls without harming urethane.

-

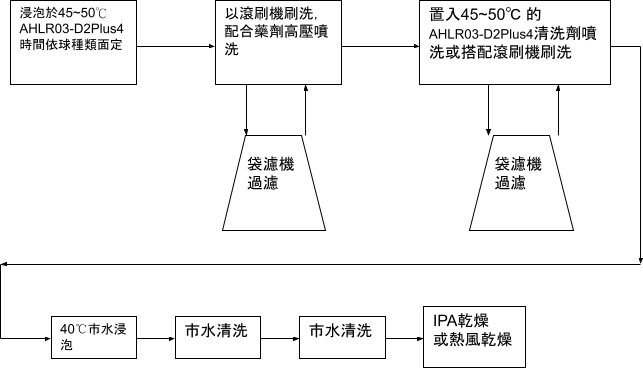

Suggested process: In mass production, a rolling brush machine can be used instead of manual wiping to improve efficiency (cleaning process as shown in the figure below).

-

Questions and discussions:

10.1 The spherical shell in the photo is judged to be scratched or worn.

It is speculated that the possible reasons are:

1. The original ball was scratched before it was fully hardened after injection. Doesn't show until primer is removed.

2. Use chemicals to heat the paint at 50°C to peel off the paint. Since it is close to the melting point of sarin, the ball is moved and rolled without the help of proper fixtures, causing abrasions.

(It is more likely that the distribution of heaters in the tank is not uniform, causing some of the spheres to come into contact with heaters and surfaces with higher temperatures, and the local temperature is higher than 60°C, causing the contact points to melt.)

Since most of the spheres are intact, it is not damage caused by chemical reaction (chemical reaction will be a comprehensive injury), more like physical scratches and abrasions.

Improvements are suggested in the following ways:

1. Lower the temperature and extend the time.

2. Reduce the power of a single heater and increase the number and area of heaters. Add a mask to keep the sphere from touching the heater.

10.2 After the agent has been used for a period of time, with the continuous release of PU ink monomers, carbon dioxide and dust in the air gradually dissolve into the agent, and it is normal that the efficiency of the agent will decrease.

The effectiveness of the potion is reduced, and new liquid can be added to restore the potency, but there is a limit.

A large number of cleaning and peeling paint; to prolong the service life of the agent, it has a great relationship with the number of tanks and pre-soaking.

With only one tank of potion, the paint stripping speed of the new solution is fast, but with each stripping of the paint, the stripping time will gradually be lengthened.

If there are more than 3 tanks of chemicals + pre-soaking tanks, the number of peeling balls will be increased by more than 5 to 10 times, and a good paint stripping rate can be maintained.

This is because the pre-soaking tank (please use the waste liquid that has been eliminated, it can be used for more than half a year. Soak it overnight at room temperature) has pre-softened the PU topcoat ~ primer.

In the first tank (please use the eliminated chemicals from the second tank to replenish, it can be used for about 1~8 weeks depending on the number of balls cleaned. 45°C, 50~120min) can capture >70~90% of PU paint.

In the 2nd tank (please use the medicine eliminated from the 3rd tank to replenish, it can be used for about 1~8 weeks to see the number of balls cleaned. 45°C, 50~120min) can capture the remaining 10~30% of PU paint.

In the third tank (new solution, it can be used for about 1~8 weeks to see the number of balls cleaned. 45°C, 50~120min), the remaining PU paint can be peeled off, as a guarantee, to ensure that all golf balls have been cleaned and cleaned. Keep this tank medicament as a new liquid that is less polluted by peeled PU monomers.

Assume that each slot is set to 50 minutes. In this way, except that the first batch of spheres takes 150 minutes to produce, a batch can be produced every 50 minutes thereafter. The actual soaking time of each batch of balls is 150 minutes.

Moreover, there is only one tank (the first tank) for the actual waste tank eliminated medicine, and there is only one tank (the third tank) for replenishing the new liquid.

However, after this arrangement, assuming that there is only a single slot, it may take 2 to 3 days to replace one slot. With 3 slot potions, it can be extended to 7~15 days before needing to replace 1 slot.

Of course, if the number of medicament tanks can be increased to 5 tanks, the output speed can be improved (each tank soaks for 30 minutes, and 5 tanks also have 150 minutes. But every 30 minutes can produce a batch)

Potion life will also be extended.

Another point to note is that the peeled PU paint should be removed as much as possible, so as to avoid the peeled PU paint being soaked in the agent and decomposing, which will reduce the life of the agent.

The specific method is: use 2 batch-type hanging baskets, the first stainless steel hanging basket has a larger aperture, lift the peeled golf balls and move them to another tank for cleaning. The aperture of the second stainless steel hanging basket is tight, allowing only the medicine to flow through.

Every time several batches are cleaned, the second stainless steel hanging basket is hoisted to remove the PU filter residue falling off on it. The first hanging basket is inside the second hanging basket, and the second hanging basket is inside the stainless steel chemical tank.

According to the customer's feedback, about 100~600 balls can be peeled off per kilogram of medicine (different balls, the number is different, the difference is a bit big).