-

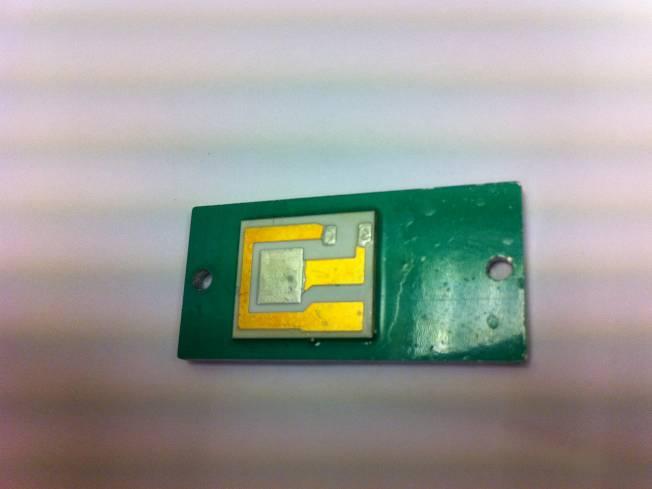

before cleaning

-

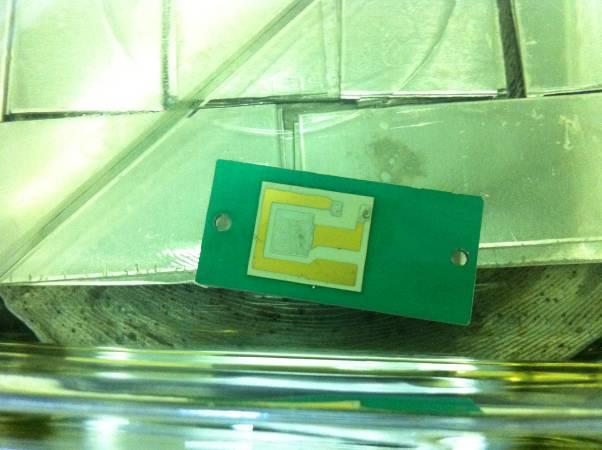

Add AHLR03, soak at 70degC for 10min, take it out and clean it with a high-pressure water jet.

-

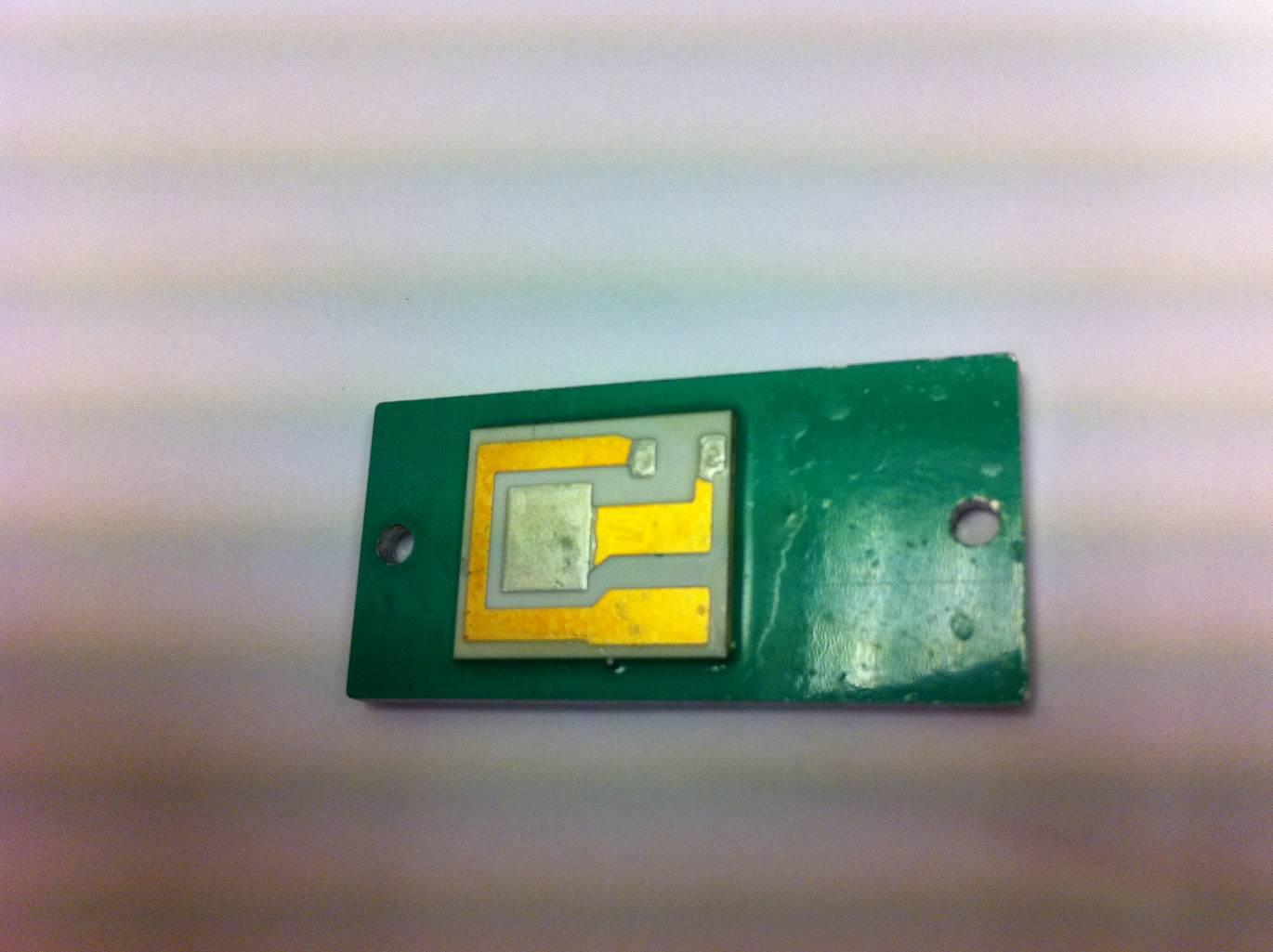

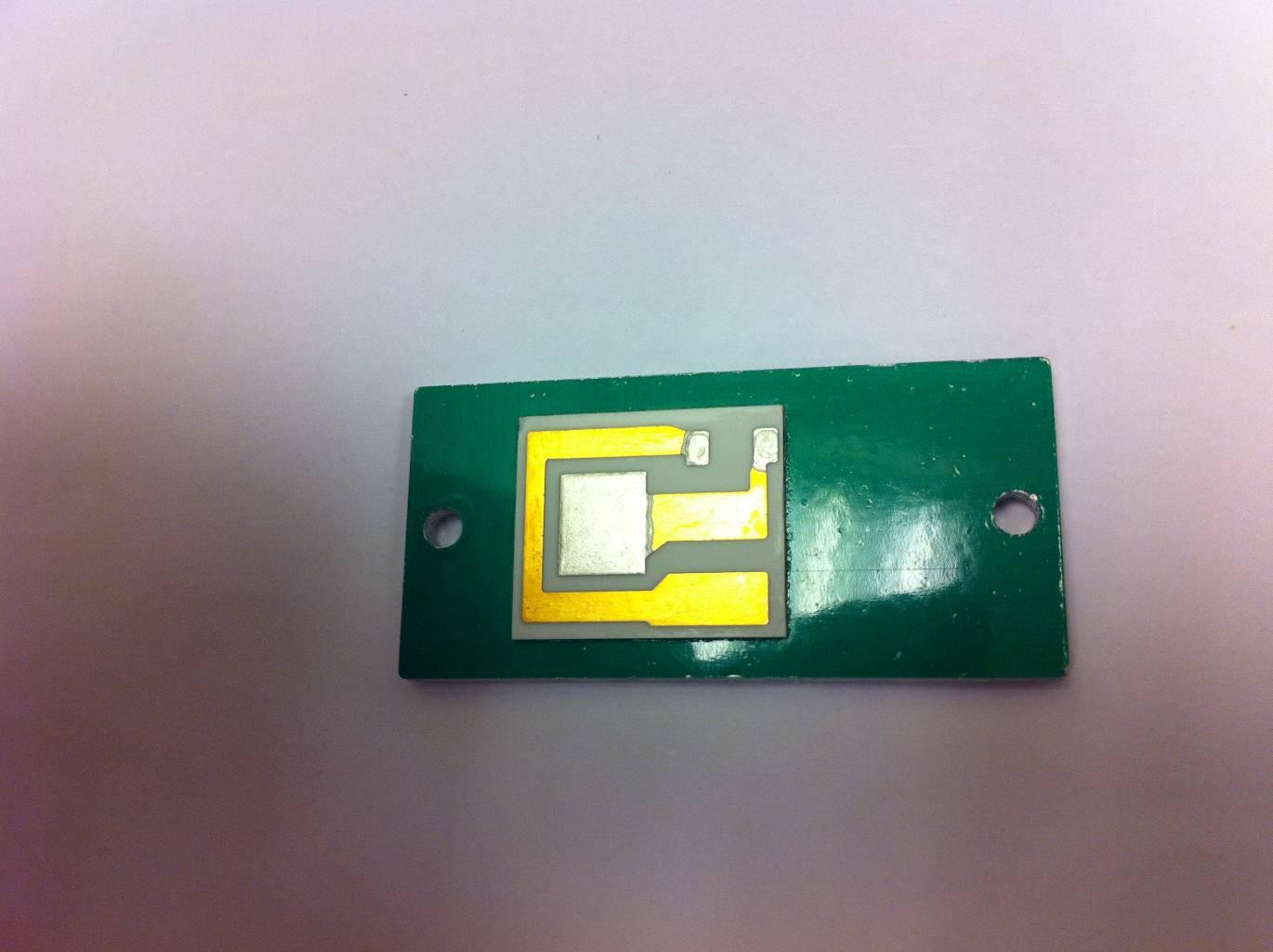

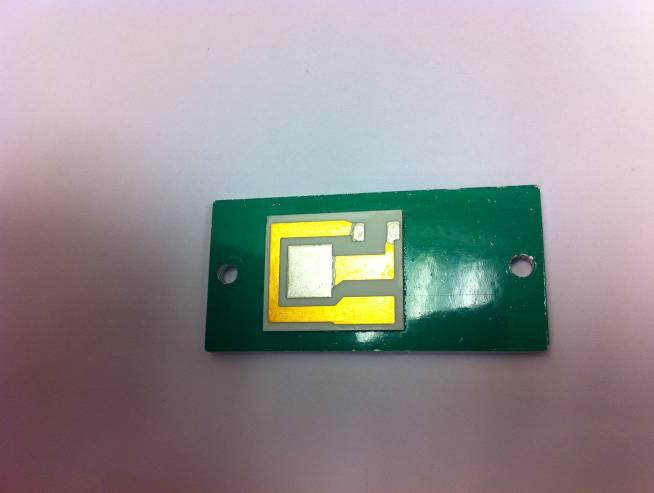

After cleaning.

-

Compare before and after cleaning.

-

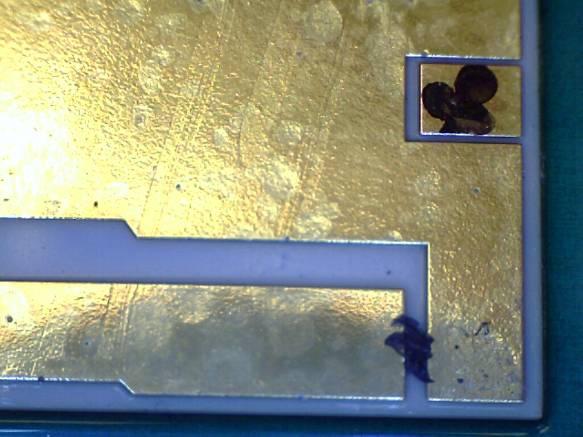

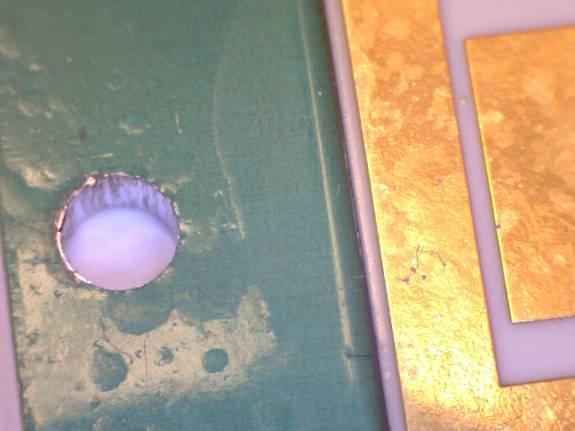

Repeat the test and observe with a microscope. Before washing.

-

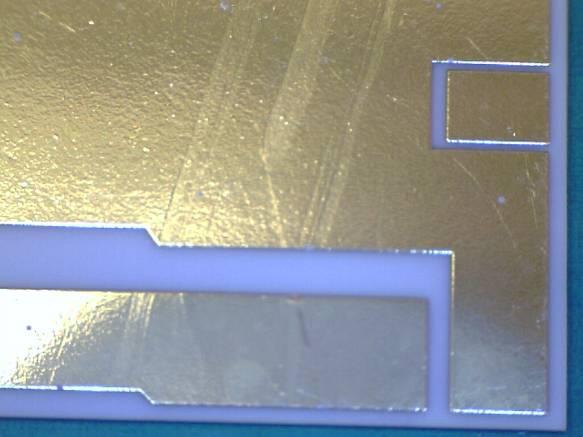

Repeat the test and observe with a microscope. After cleaning.

-

Compare. Repeat the test, observing under the microscope before and after cleaning. The flux above has been completely removed.

-

Suggestions and discussions:

8.1 AHLR03 confirms that it is effective to clean the flux on the PCB; and it will not harm the green paint and the aluminum board on the back.

8.2 Heating at 70degC is effective for flux cleaning. You can try lowering the temperature to clean.

4.3 It is easier to wipe and remove with a dust-free cloth than to spray with a high-pressure water gun. Cleaning machinery and equipment can be considered to be equipped with brushes for scrubbing.

8.3 The surfactant used in AHLR03 is biodegradable, has low toxicity, high boiling point (>255°C), high flash point (>105°C), and low volatilization rate: 0.01 (butyl acetate = 1). It has a slight smell when used, and can replace natural glue removers, reduce VOC and odor tolerance of the user unit.