-

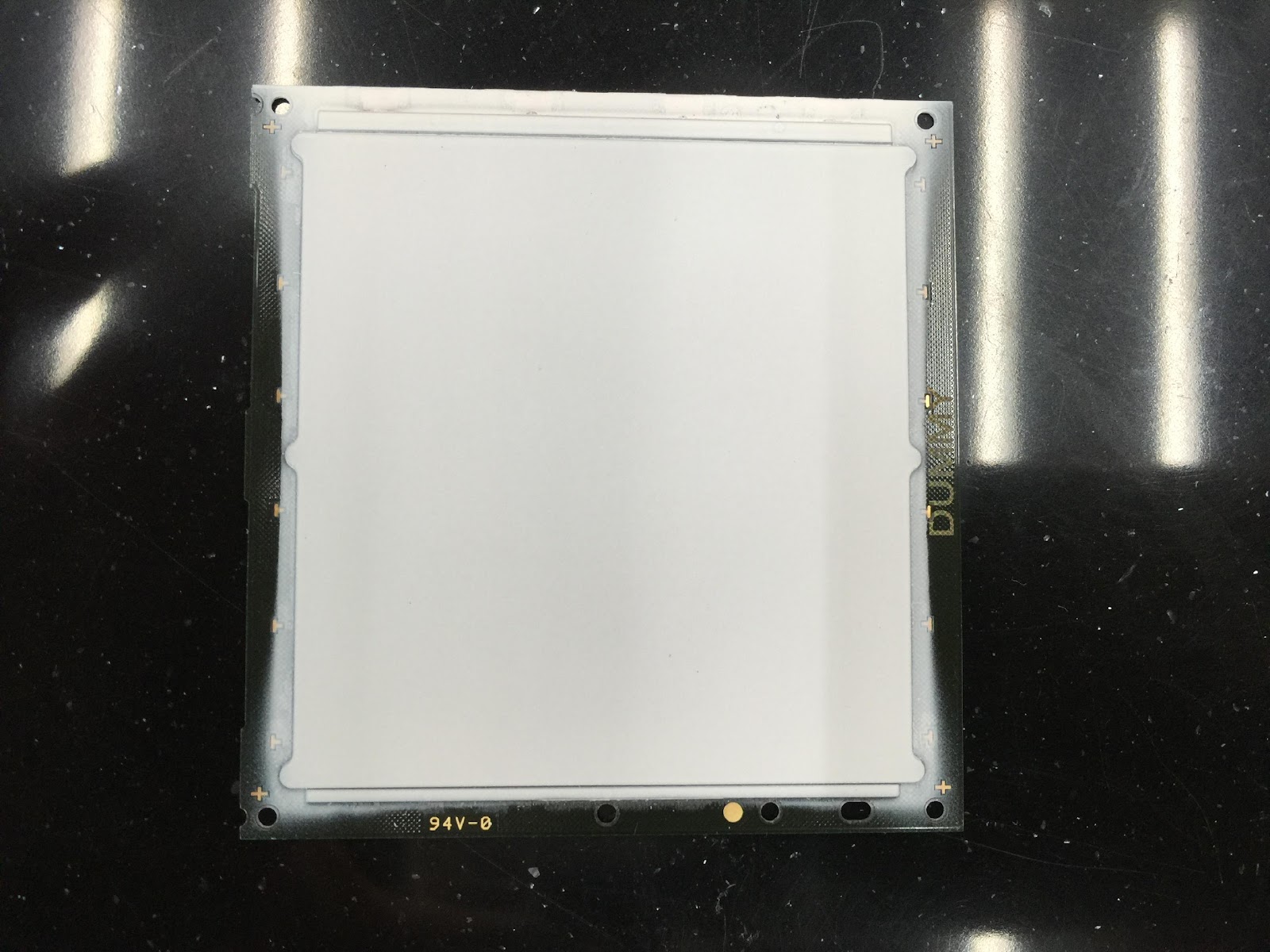

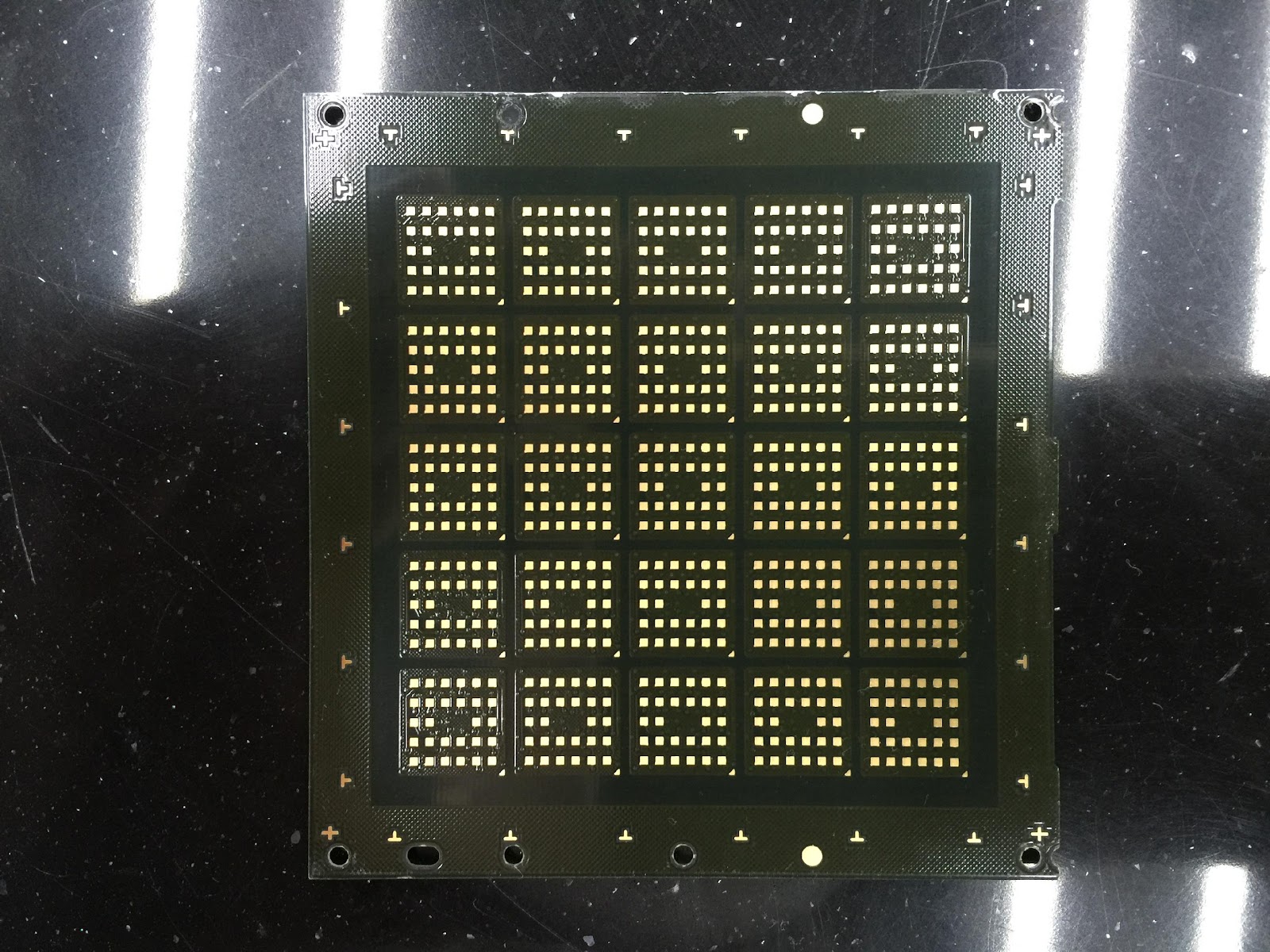

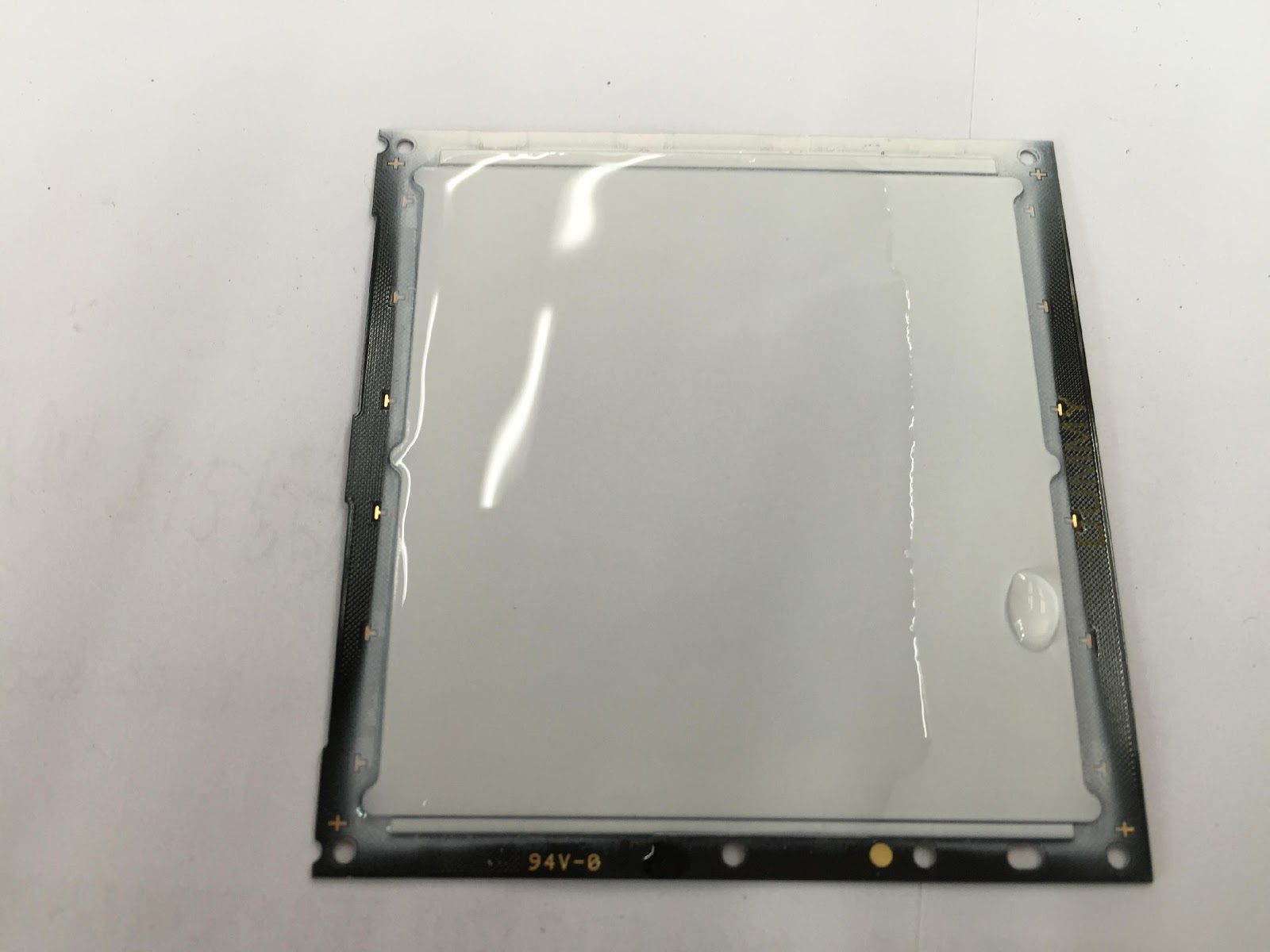

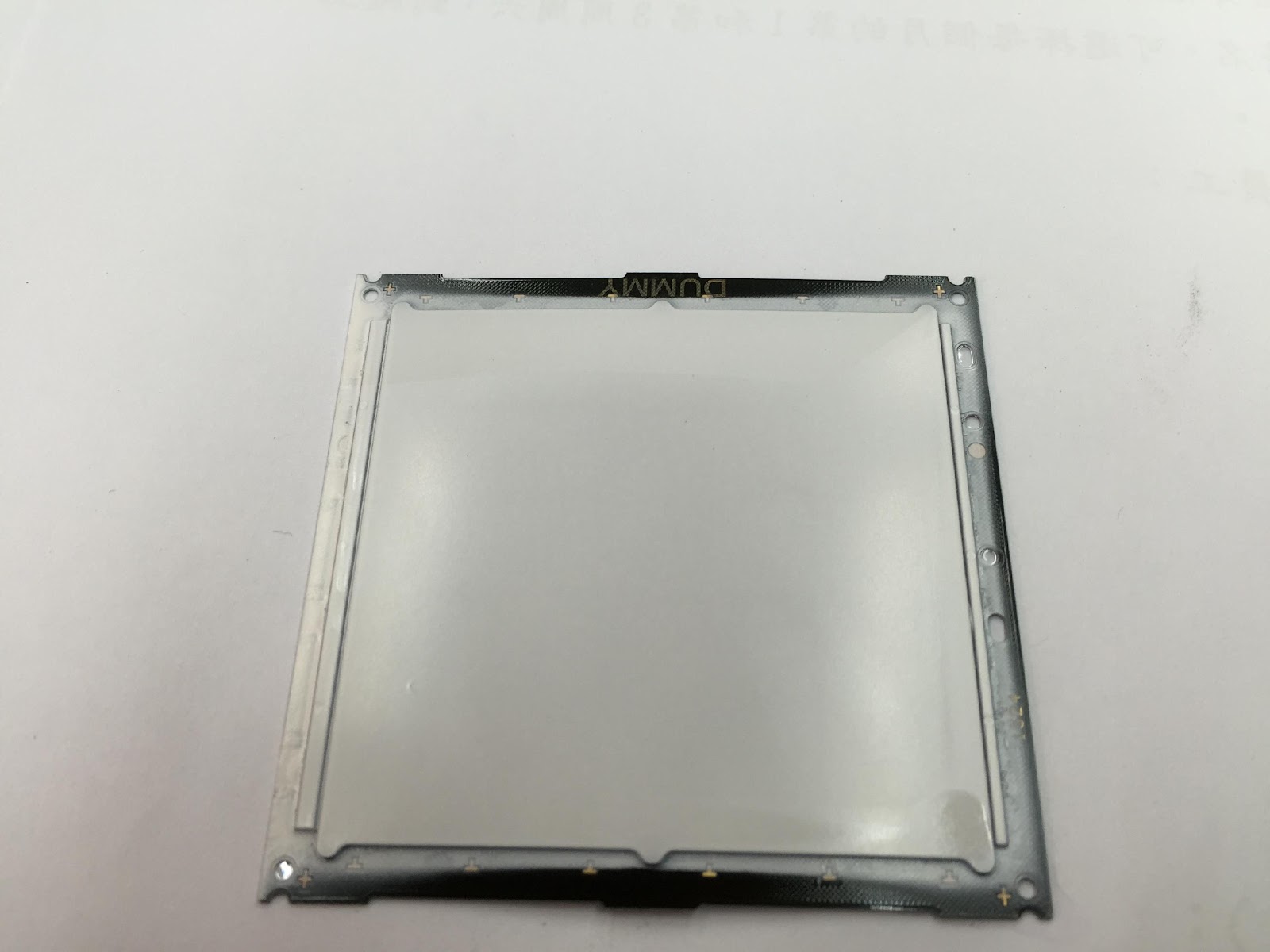

Sample before coating, covered with white hardened ink plate, not yet cut into IC wafers.

-

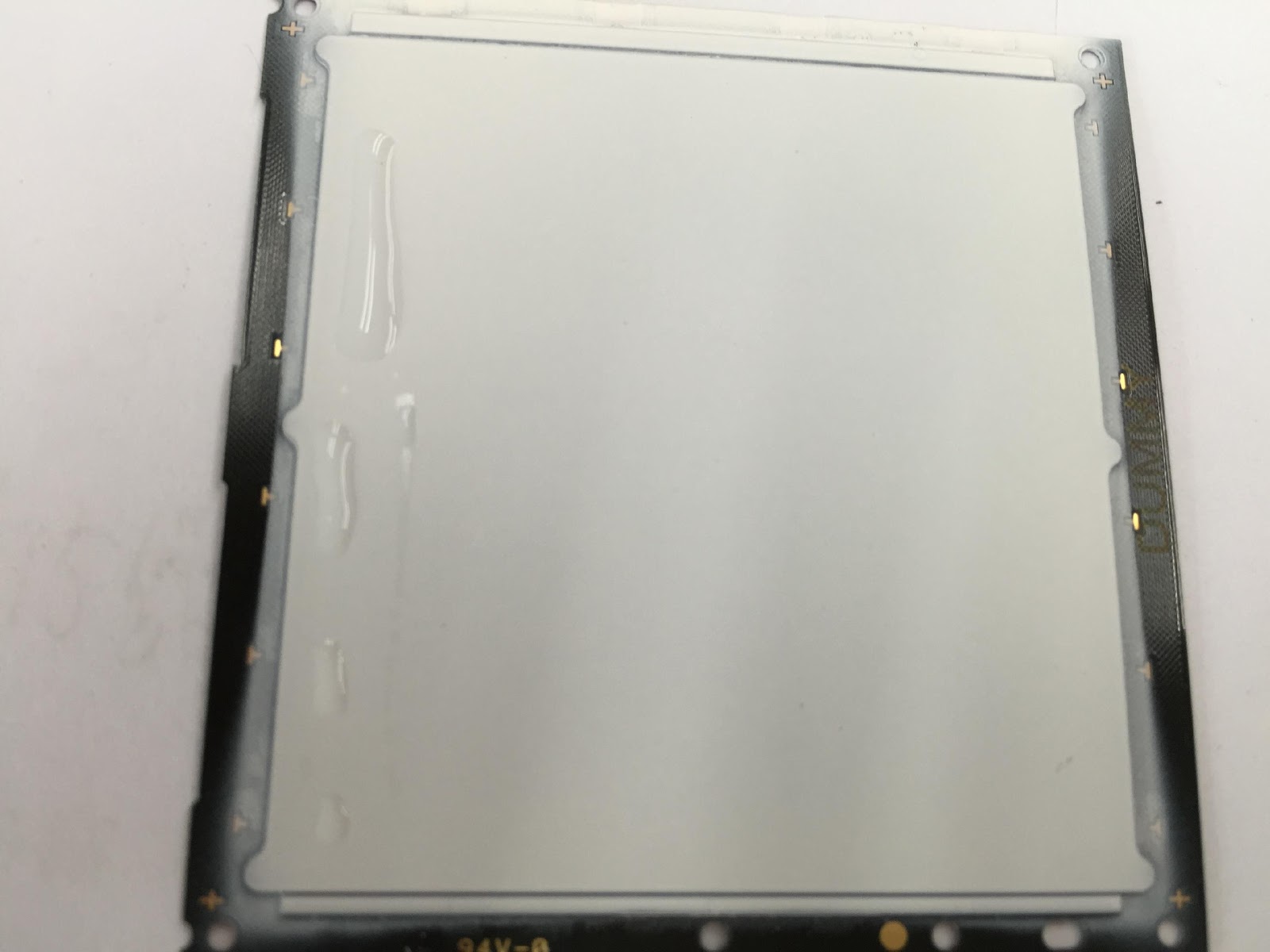

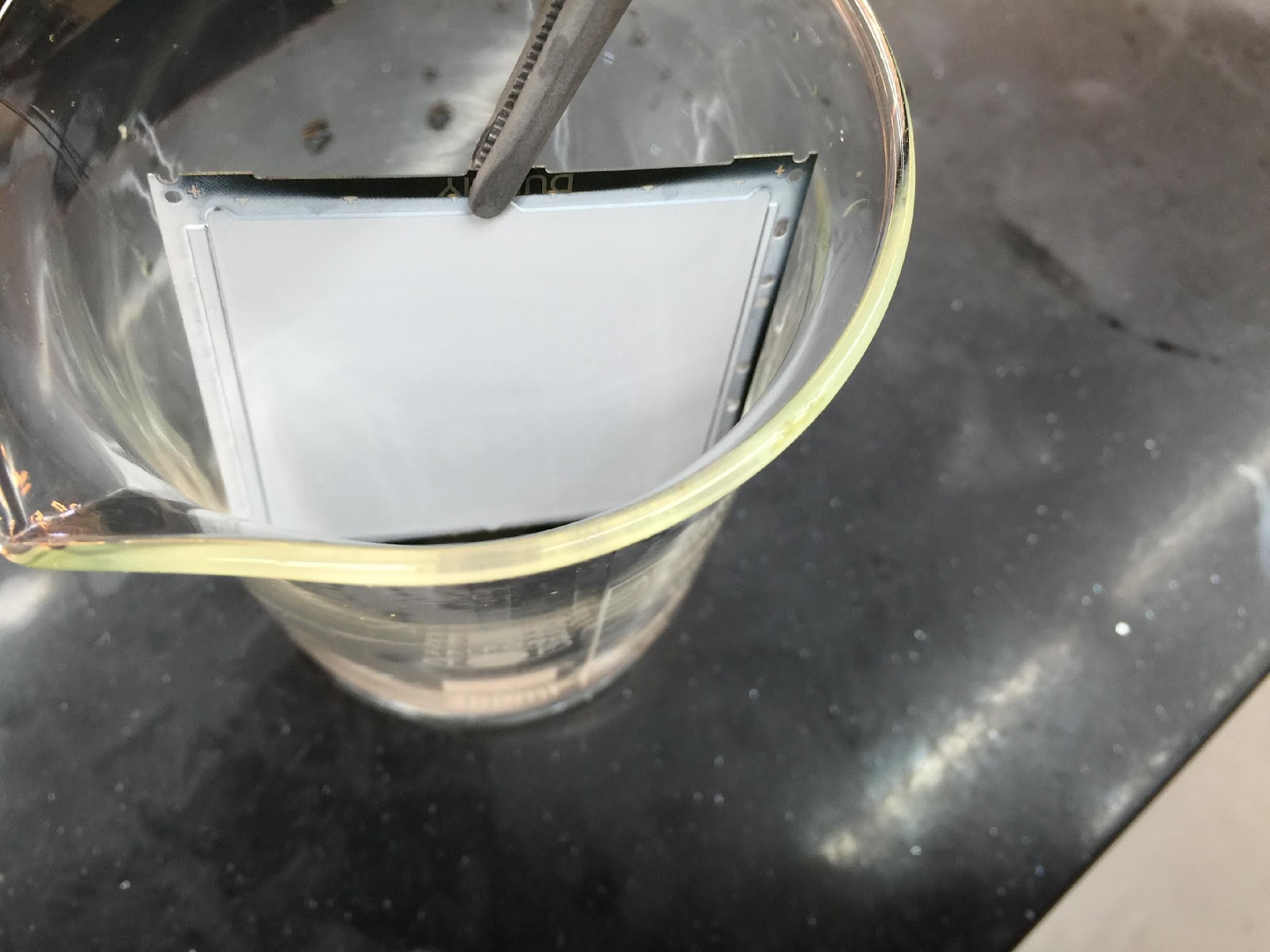

Use Xiwei TM Razor Protection Fluids LCP01 and LCP02, which can evenly cover metal workpieces and protect metals for laser cutting, and apply them on the plate covered with white hardening ink. The surface of this workpiece was found to have insufficient affinity for LCP01 and LCP02. The applied Raiche protective liquid will condense into water droplets, which cannot form a uniform protective film. The drop-shaped liquid on the left of the picture below is the situation where LCP01 gradually condenses into a drop-like shape after rubbing LCP01 with a cotton swab.

-

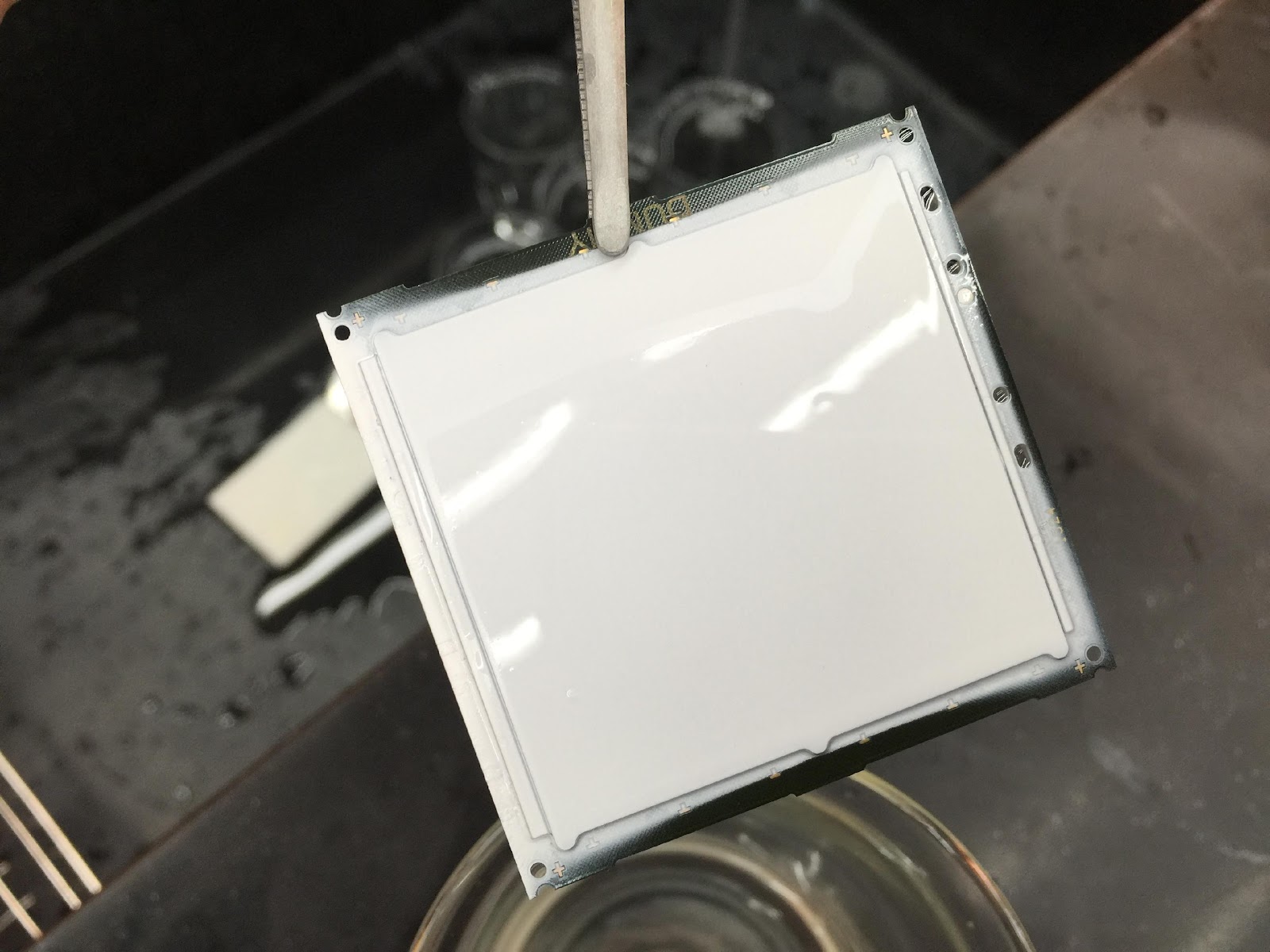

For the development of workpieces covered with resin, Xiwei TM Raycut Protective Liquid LCP03 was developed. It was found that LCP03 could be evenly coated on this plate covered with white hardened ink. The left side of the picture below is the coated LCP03, and the small drop of liquid on the right is LCP02.

-

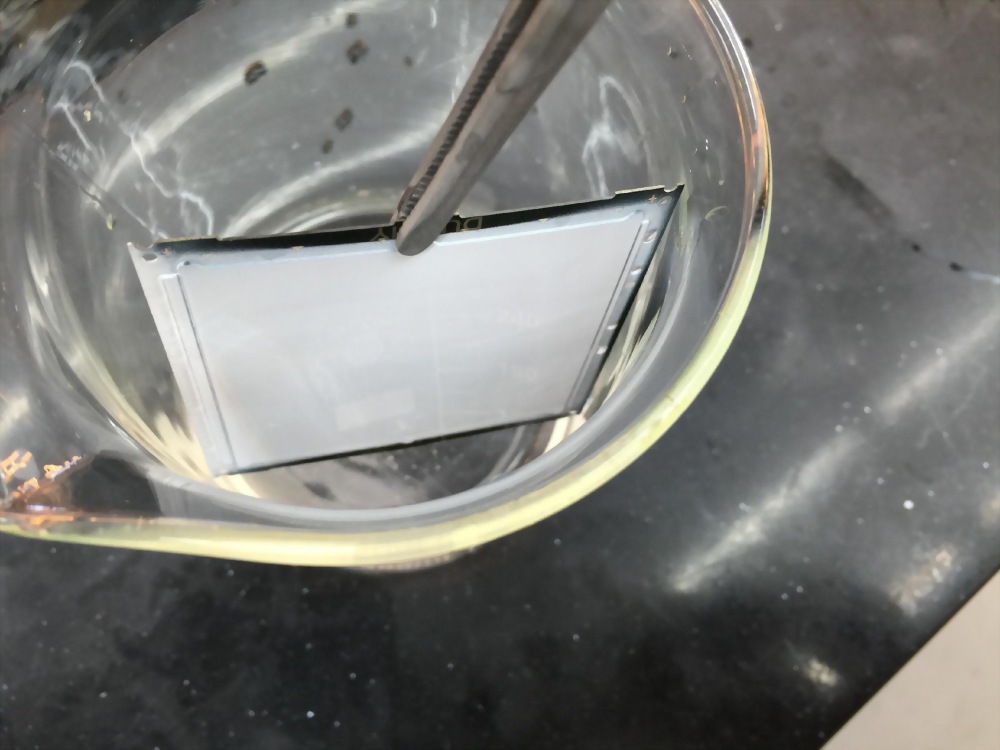

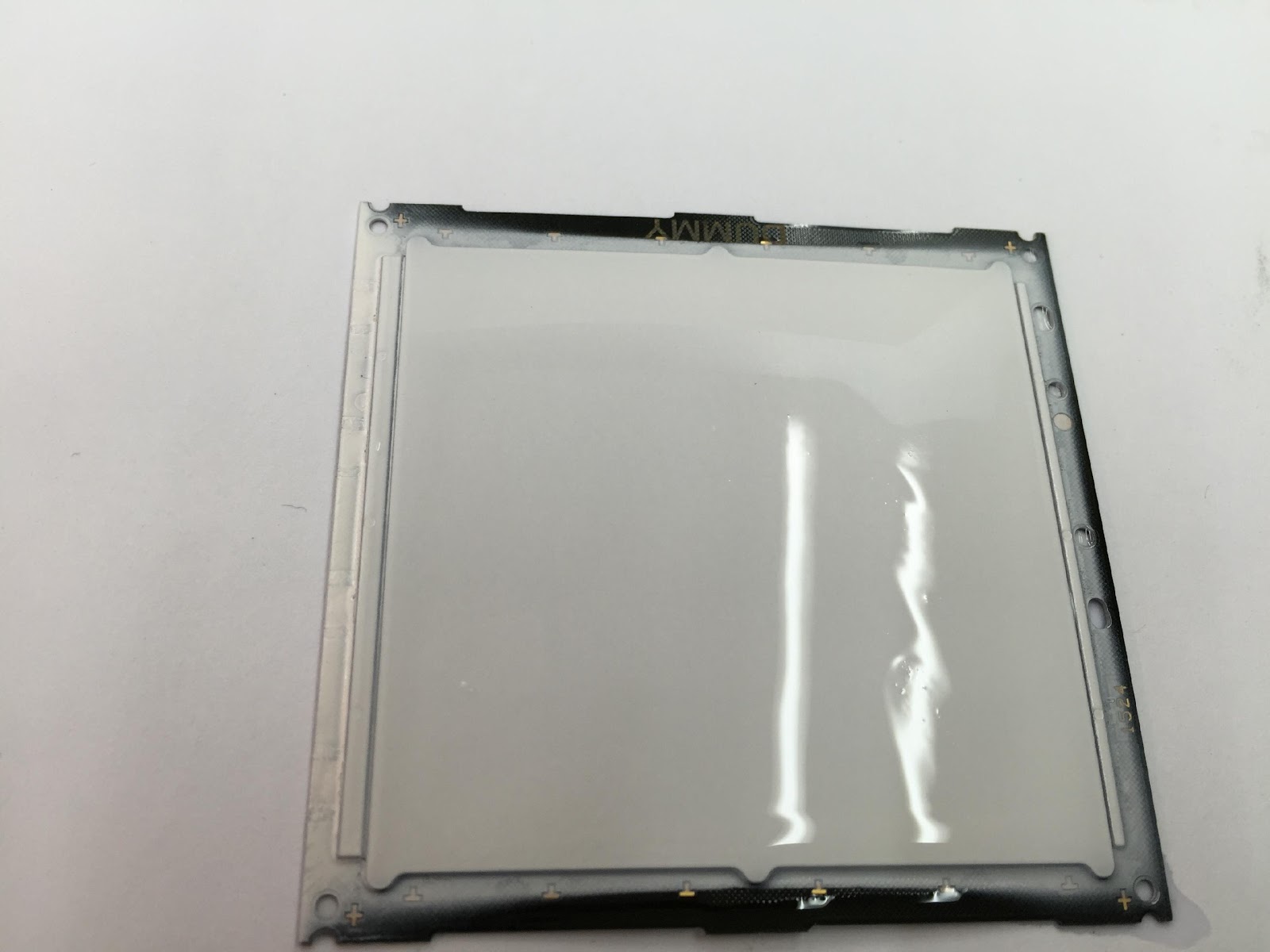

Repeat the test. Take a new plate covered with white hardened ink, soak it in LCP03 directly, and take it out immediately.

-

It is found that LCP03 can evenly adhere to the surface of the white hardened ink plate, and can also form a uniform water-soluble film after drying.

-

discuss.

6.1 Xiwei TM Raycut Protective Liquid LCP03 can evenly adhere to the surface of the white hardened ink plate to form a water-soluble protective film. To avoid the scorching marks on the workpiece caused by excessive heat at the edge of the light during laser cutting. It can also protect the workpiece from the toner and particle pollution released during laser cutting. Because toner and particles will adhere to the protective film, the protective film can be easily removed by rinsing with warm water.

6.2 Method of coating LCP03: It is recommended to soak the workpiece in LCP03 directly, then take it out immediately, and let it stand vertically until it drips dry, or use a centrifuge to dry it. Or apply by rotary spraying. This excess liquid can be shaken off and the film on the surface will be more even.