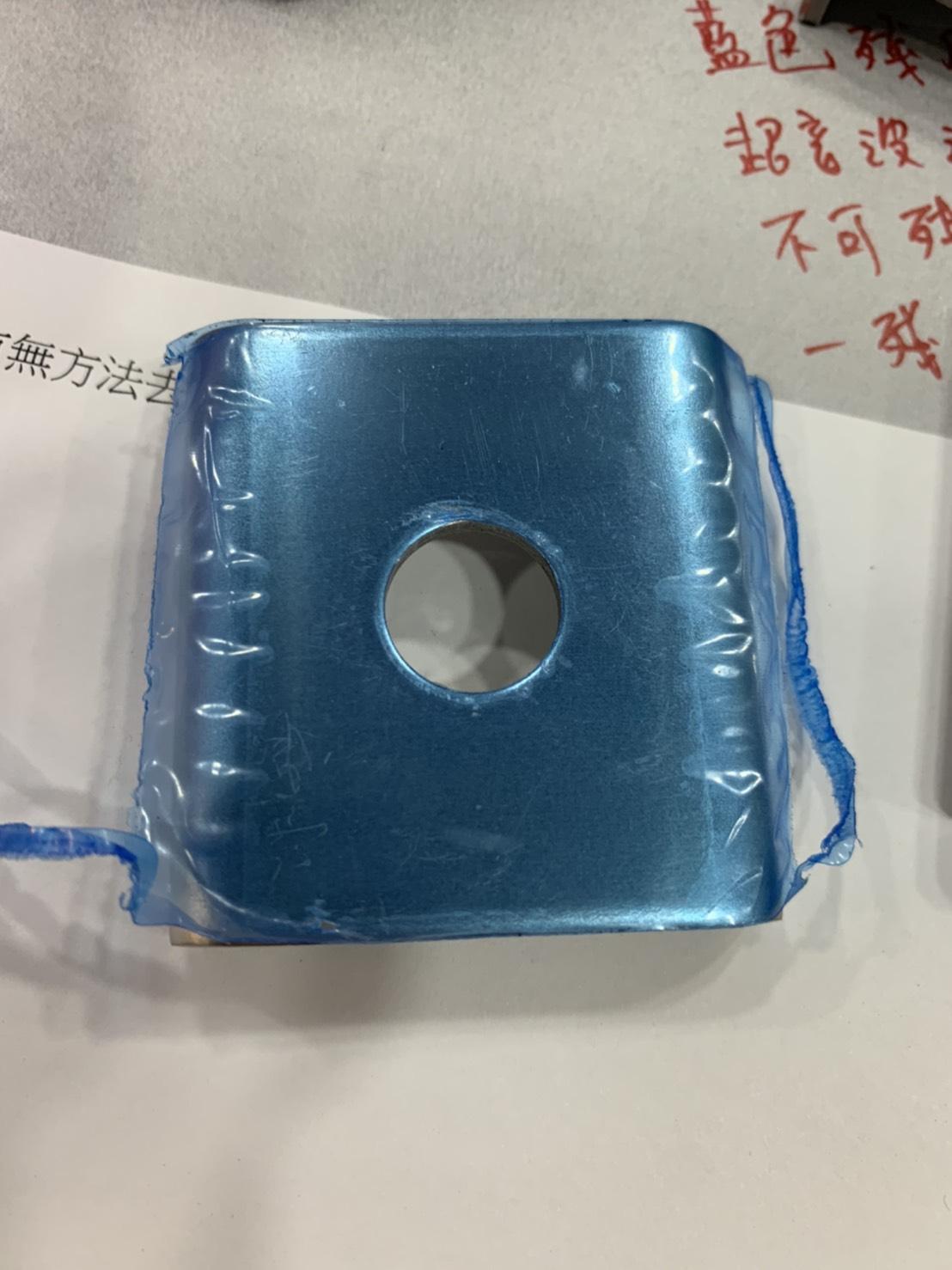

Workpiece description: This stainless steel workpiece has some marks marked with a strange pen, and it is covered with residual glue, particles, and stickers that have not been removed.

-

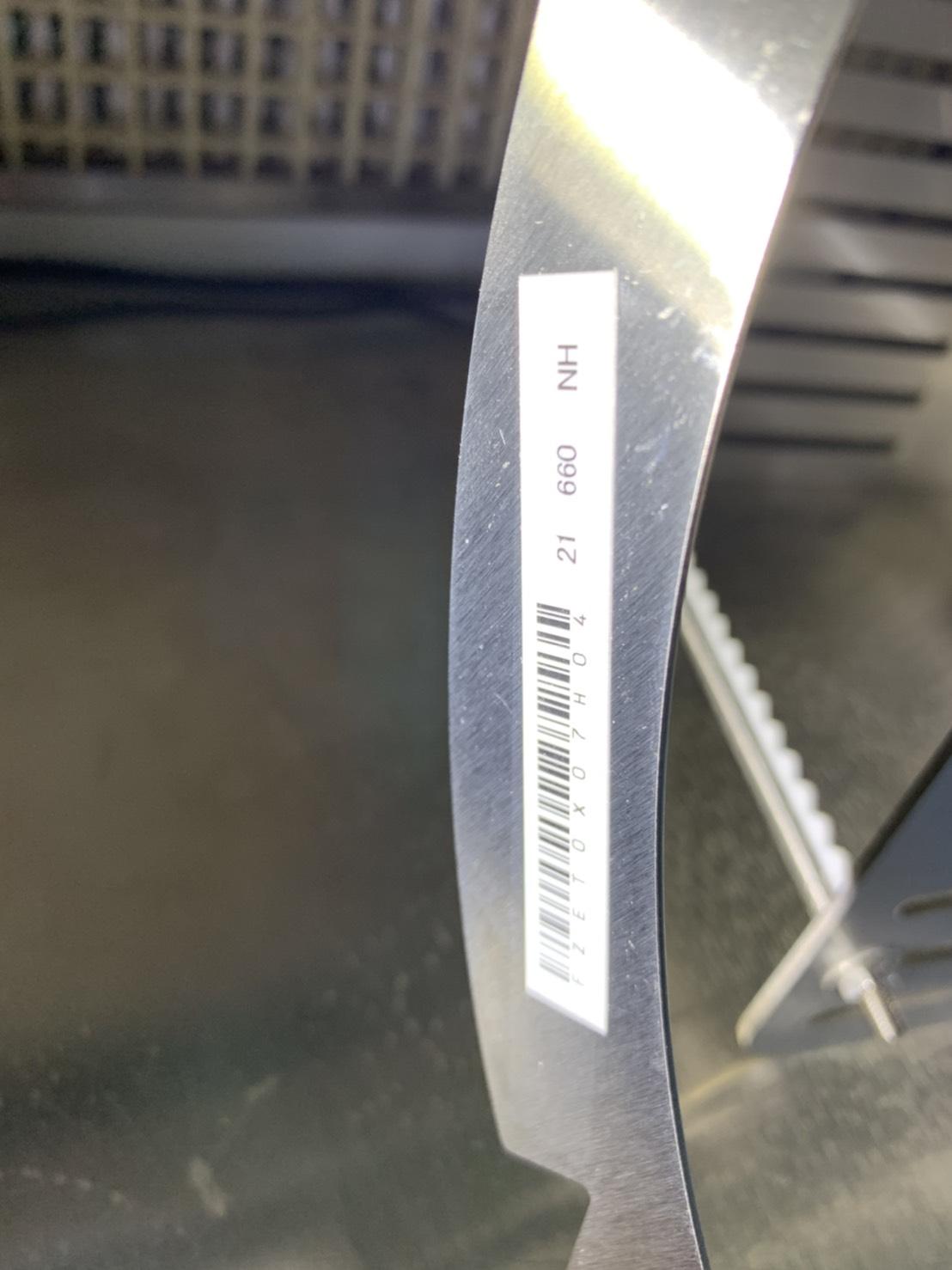

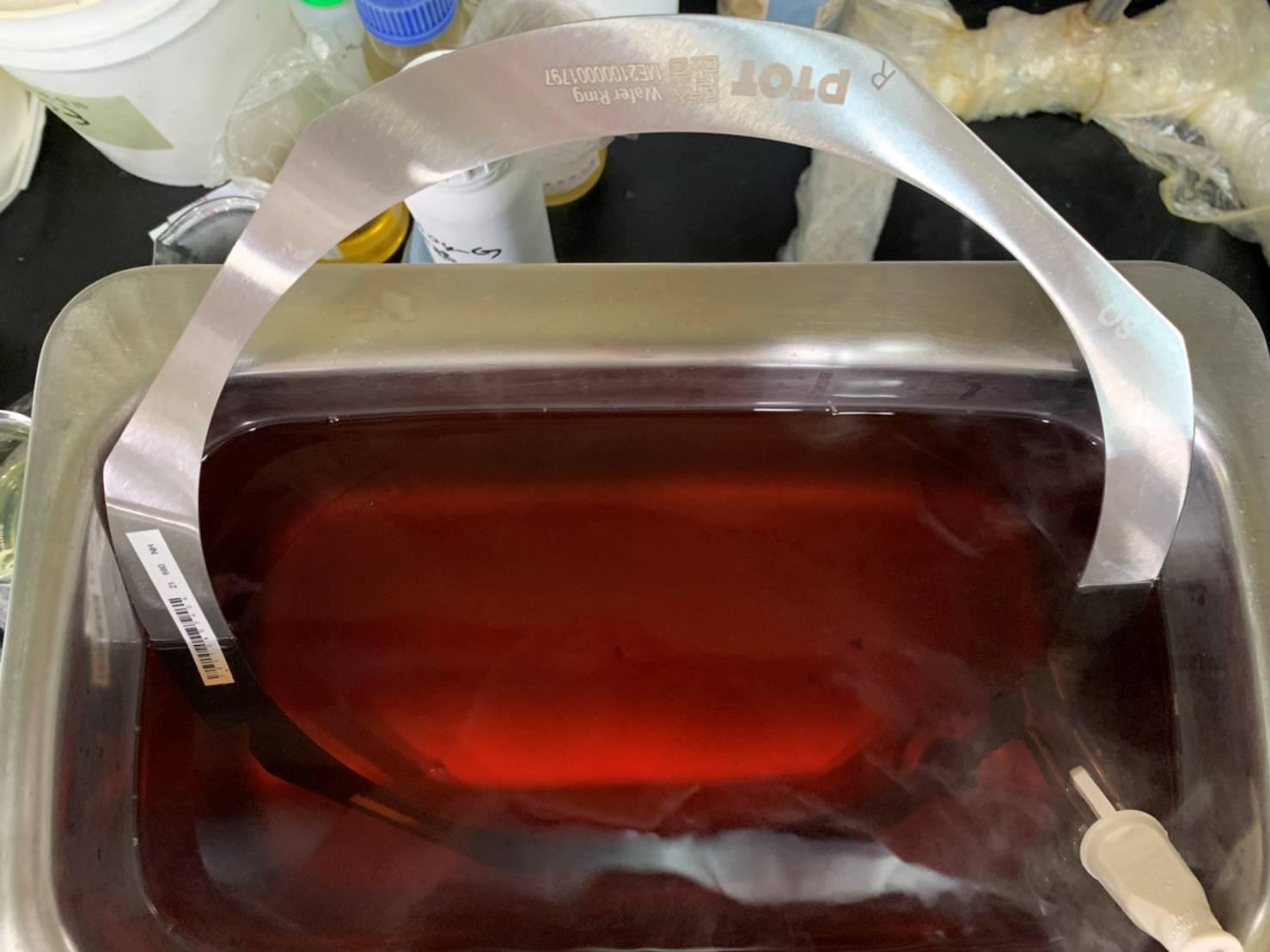

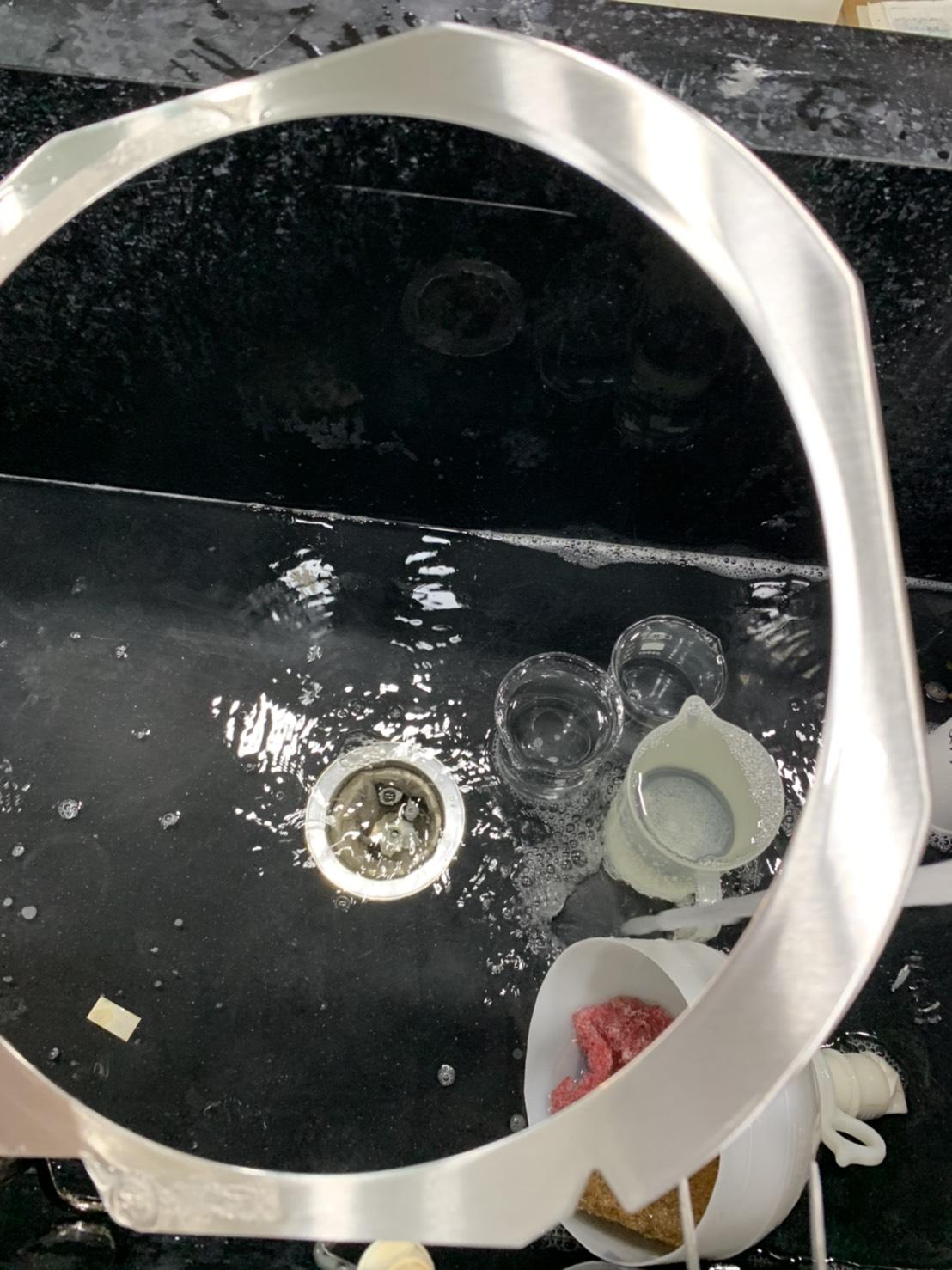

Test the first stainless steel Wafer Ring. Before washing, it is covered with residual glue, particles, and stickers that have not been removed.

-

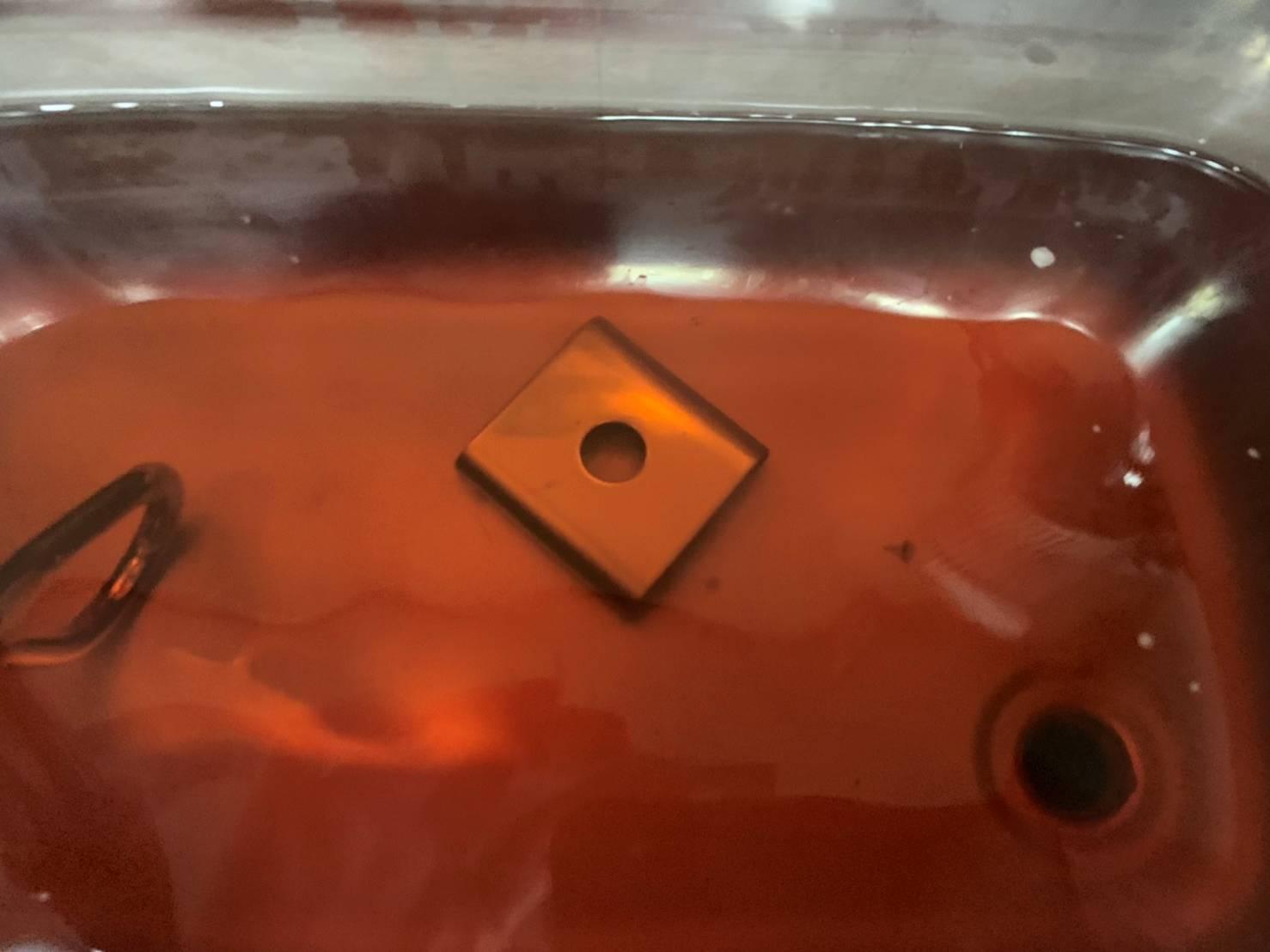

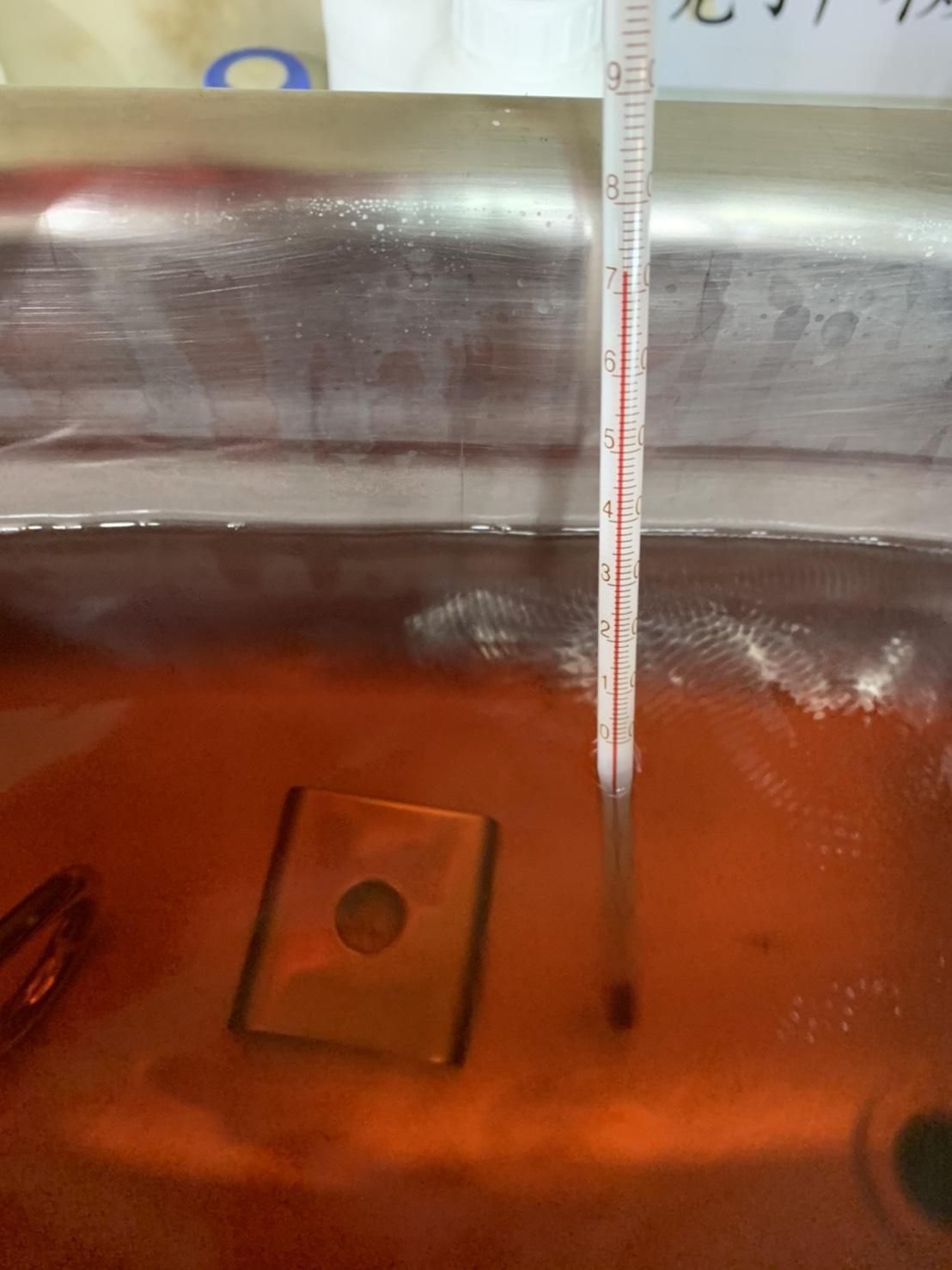

Use microdust cleaner PTC-3b, place the agent in an ultrasonic cleaner (40KHz, 50W/L) and heat to 60°C. Put in a stainless steel Wafer Ring, shake and wash for 5 minutes.

-

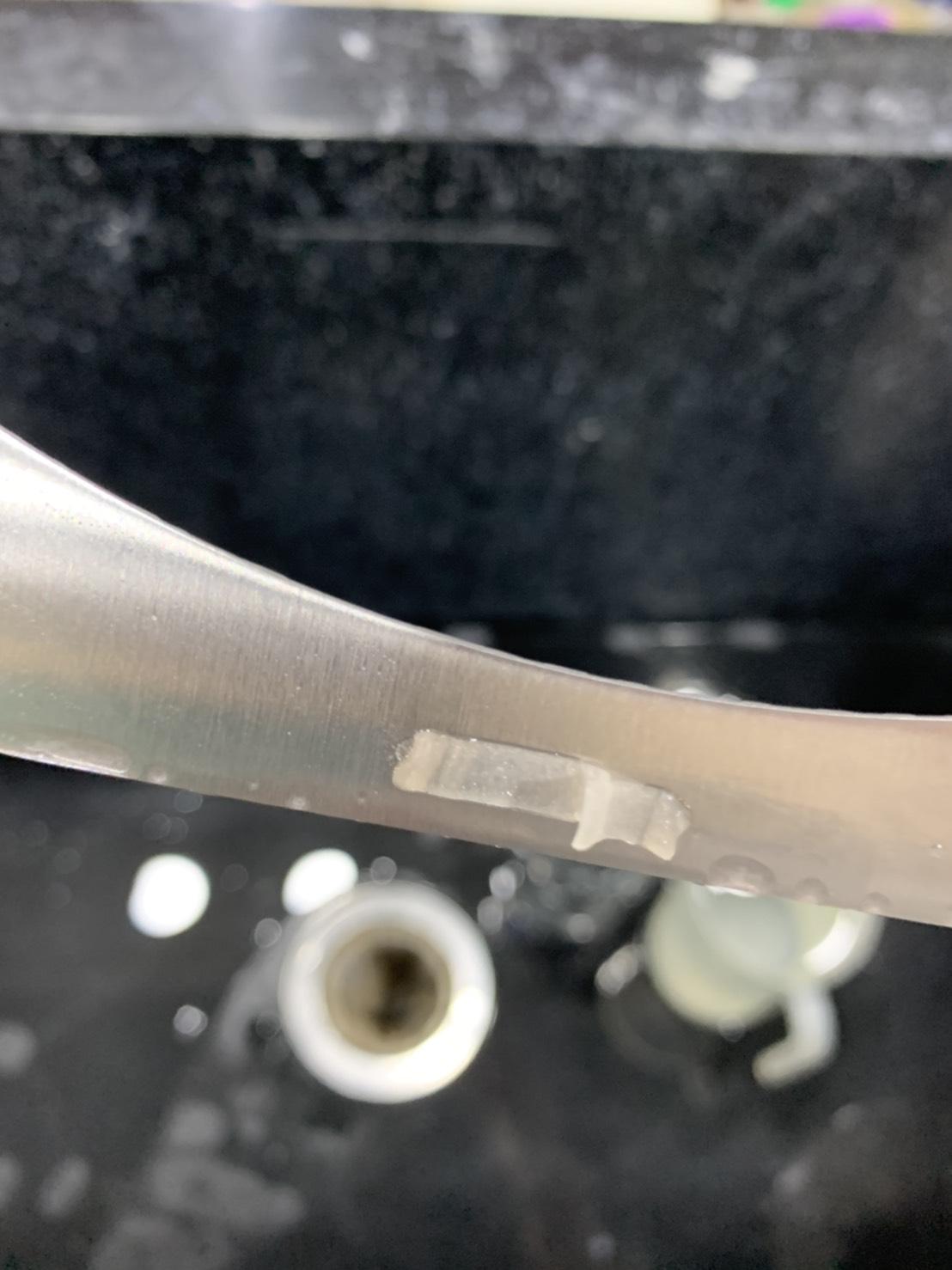

After cleaning with ultrasonic vibration for 5 minutes, take it out, and find that the residual glue on the surface has been removed. But the remnants of the stickers still remain.

-

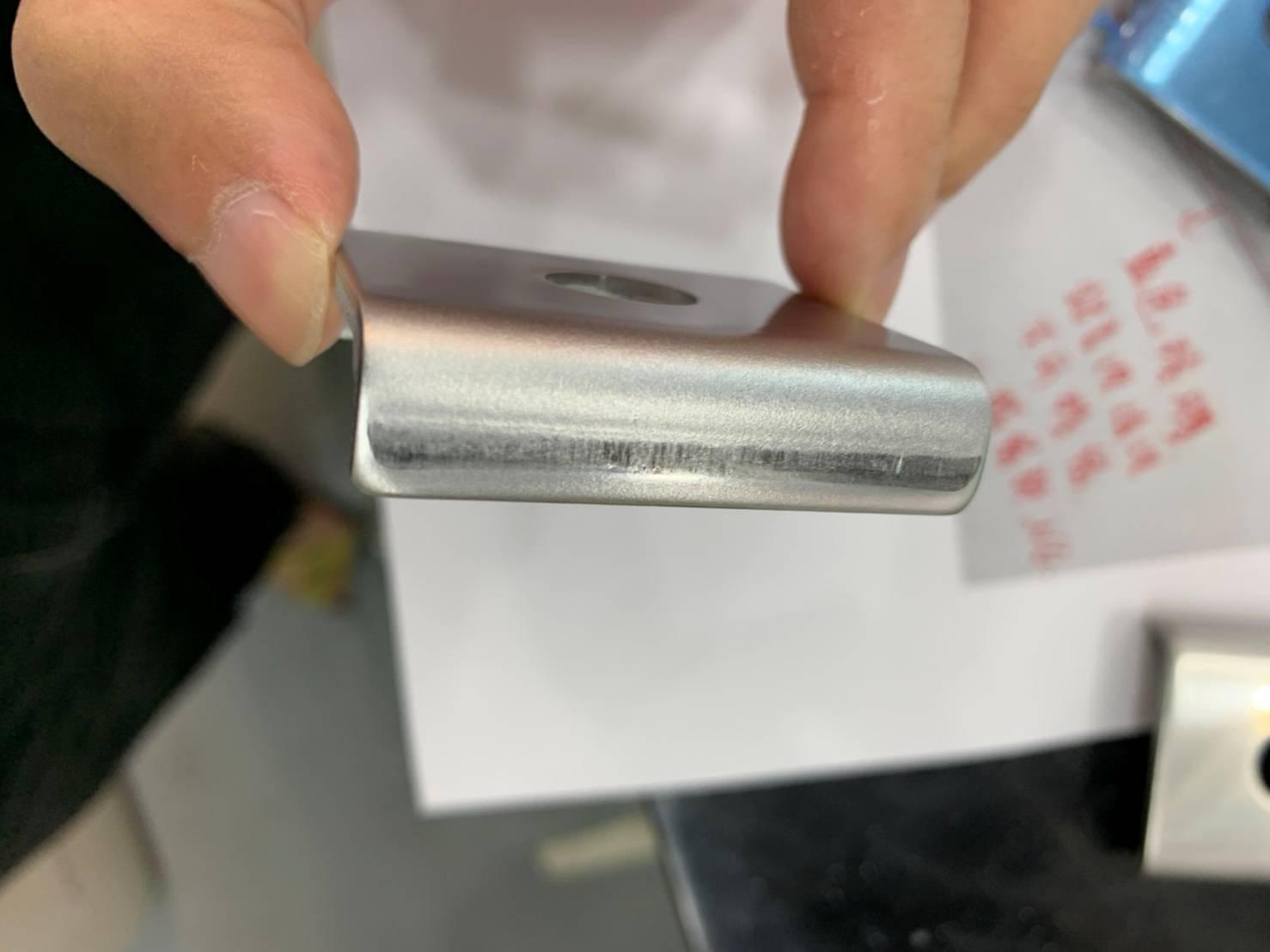

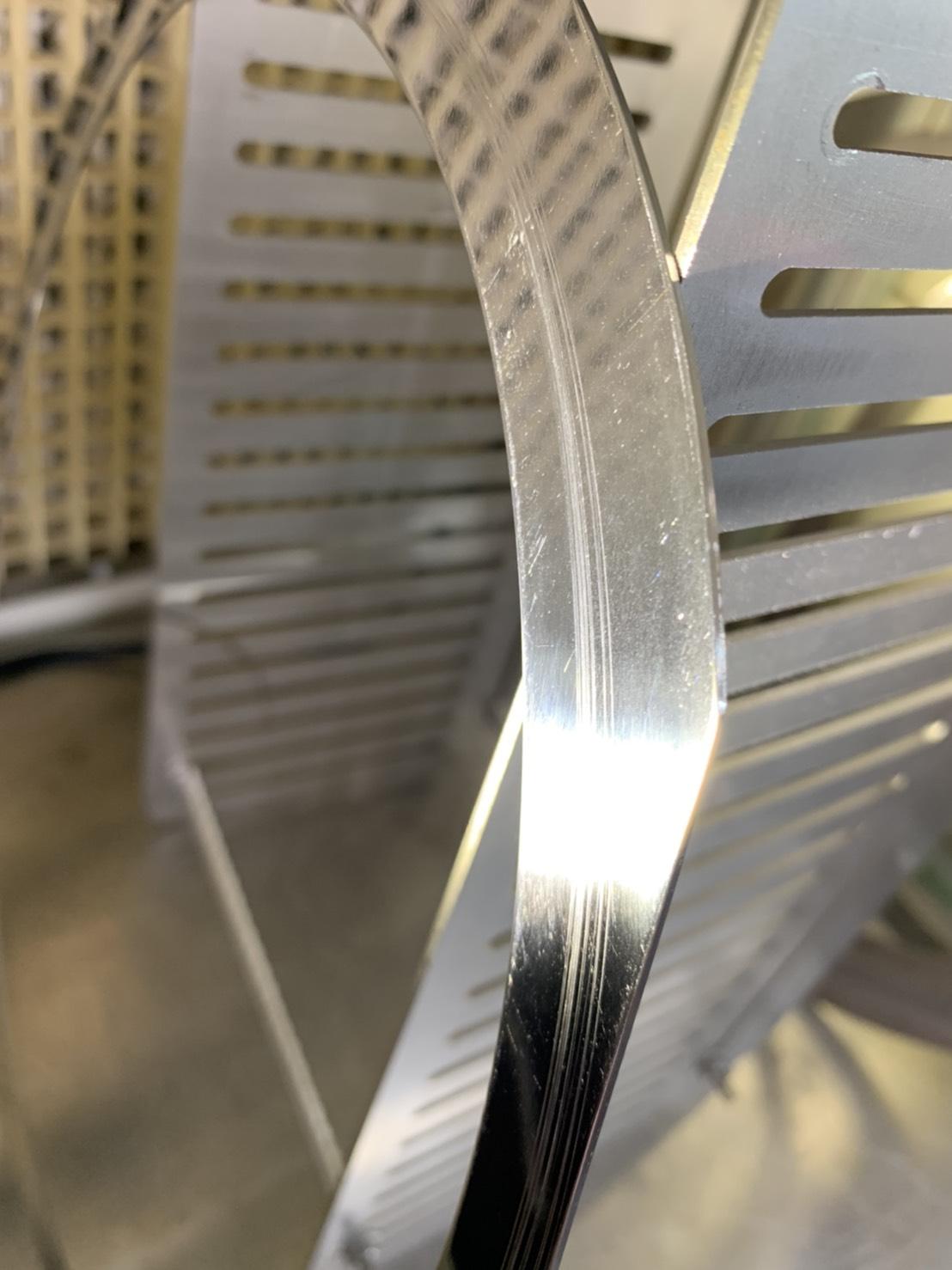

Take it out and rinse it with clean water. It is found that the residual glue and Particle on the surface have been completely removed. White spots under strong light are scratches.

-

Extend the wash time by 30 minutes. Try to remove the remaining paper from the sticker by prolonging the cleaning time.

-

It was found that although it was cleaned with ultrasonic vibration for 30 minutes and then taken out, the residual paper of the sticker still remained, but the adhesive on the sticker had swelled and lost its stickiness. It can be completely cleaned by extending the cleaning for 10 minutes, but the cleaning time is increased by 40 minutes, and the efficiency is not good.

-

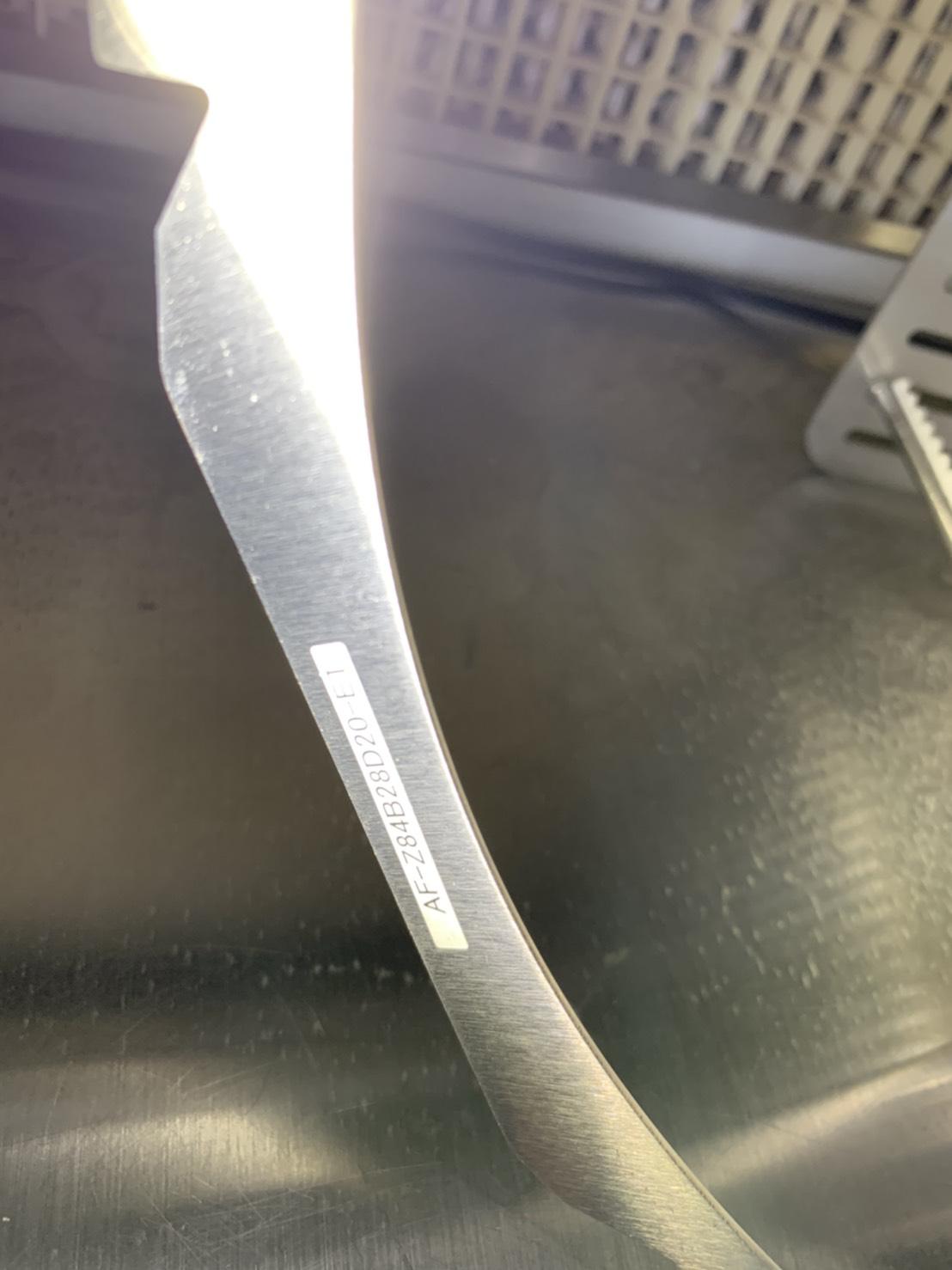

Rotate the stainless steel Wafer Ring, put another sticker into the micro-dust cleaner PTC-3b, and clean it with ultrasonic vibration for 30 minutes. After taking it out, I found that the other sticker was a plastic sticker, and the medicine could not penetrate it. Although this plastic sticker agent can wash off the surface ink, the back glue of the plastic sticker does not swell. Only the residual glue near the edge of the sticker has decomposed and slightly lifted. Finally, tear it off with tweezers, and then use the micro-dust cleaner PTC-3b to clean the residual glue around the sticker and shake it under ultrasonic waves for 5 minutes, and then it can be completely removed. It is found that cleaning with chemicals is not efficient enough to completely remove the stickers.

-

Take it out and rinse it with clean water. It is found that the residual glue and Particle on the surface have been completely removed. White spots under strong light are scratches.

-

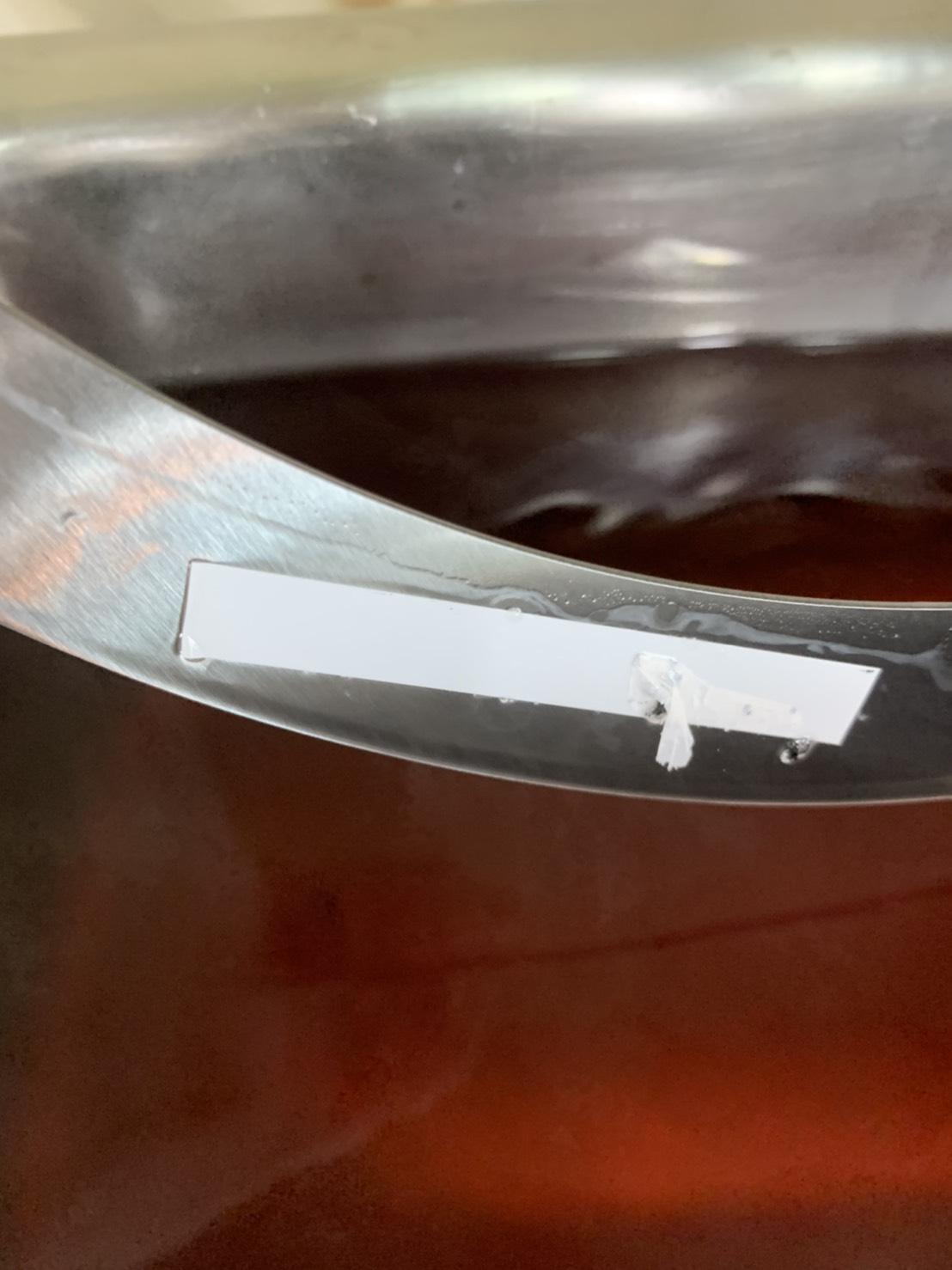

Repeat the test and take the second stainless steel Wafer Ring. The surface of this stainless steel Wafer Ring is covered with a lot of residual glue, and many marks are written on the surface with a strange pen. The picture below is before cleaning.

-

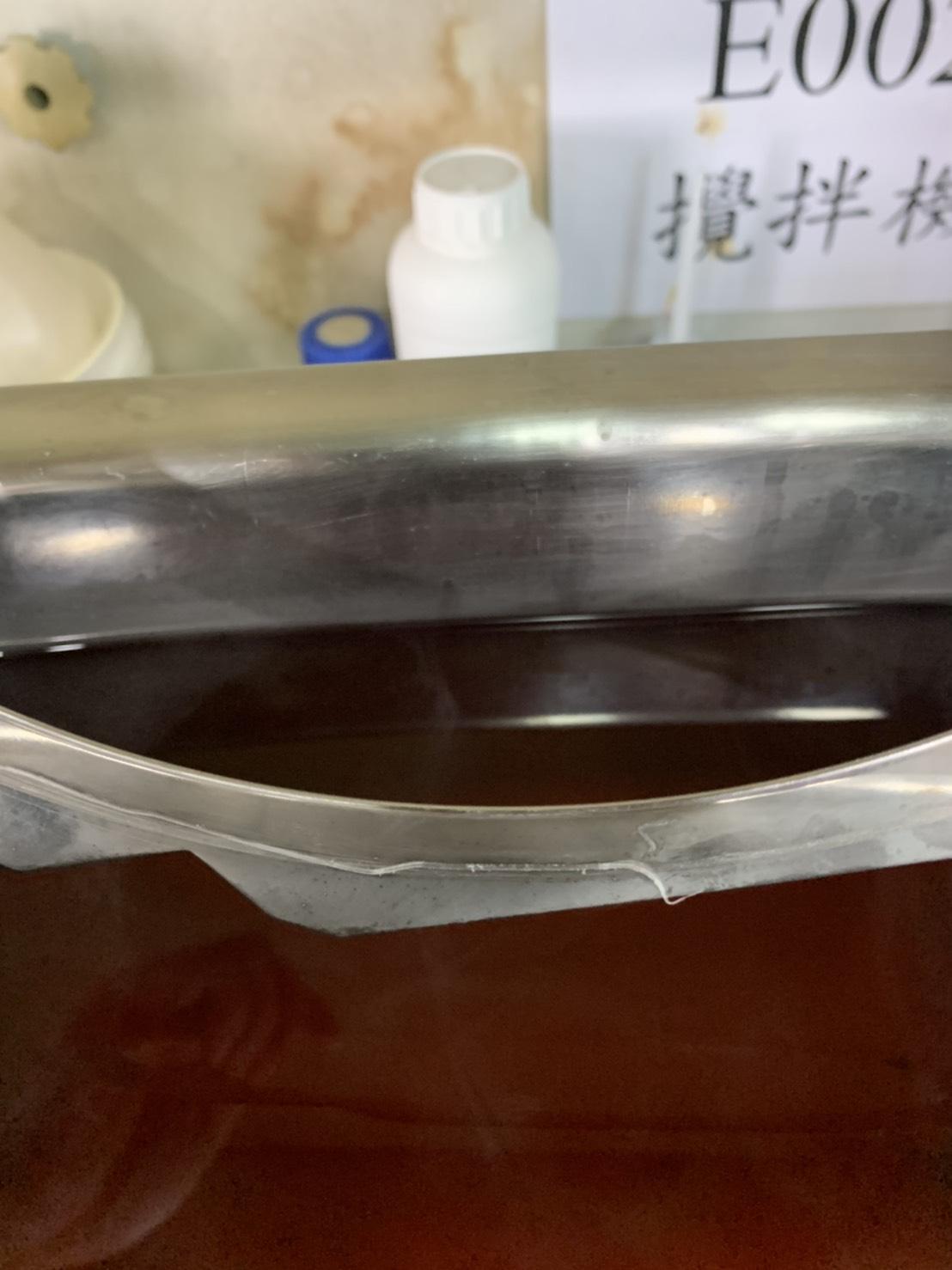

After cleaning with ultrasonic vibration for 5 minutes, I took it out, and found that the residual glue on the surface of the Wafer Ring soaked in the medicine had swollen and rotted like a snot.

-

Take it out and rinse it with clean water. It is found that the residual glue and Particle on the surface have been completely removed. Where the agent is not soaked, the residual glue cannot be completely removed by washing with water.

-

After standing to air dry. It was found that the residual glue and particles on the surface of the Wafer Ring soaked in the chemical had been completely removed.

-

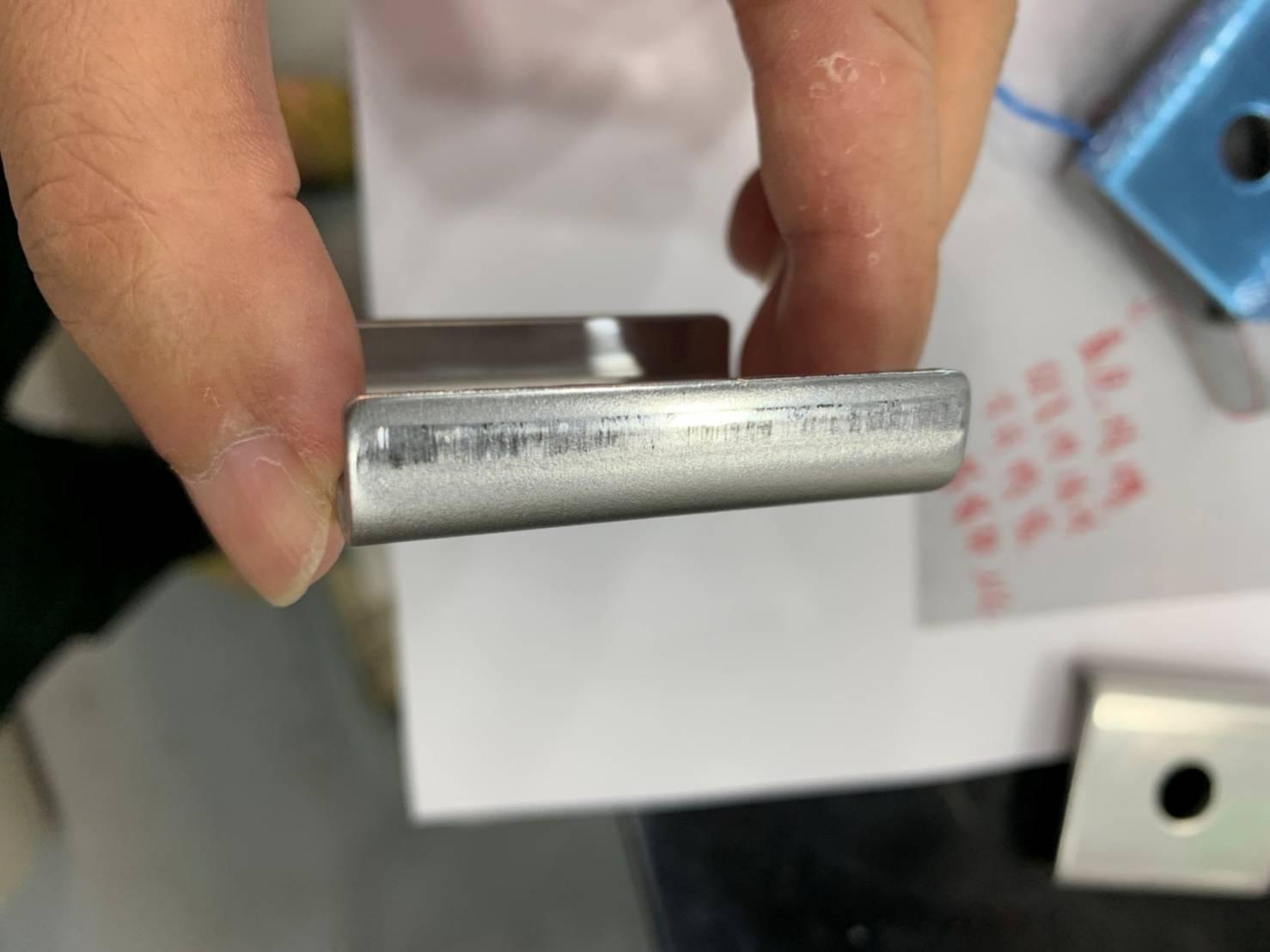

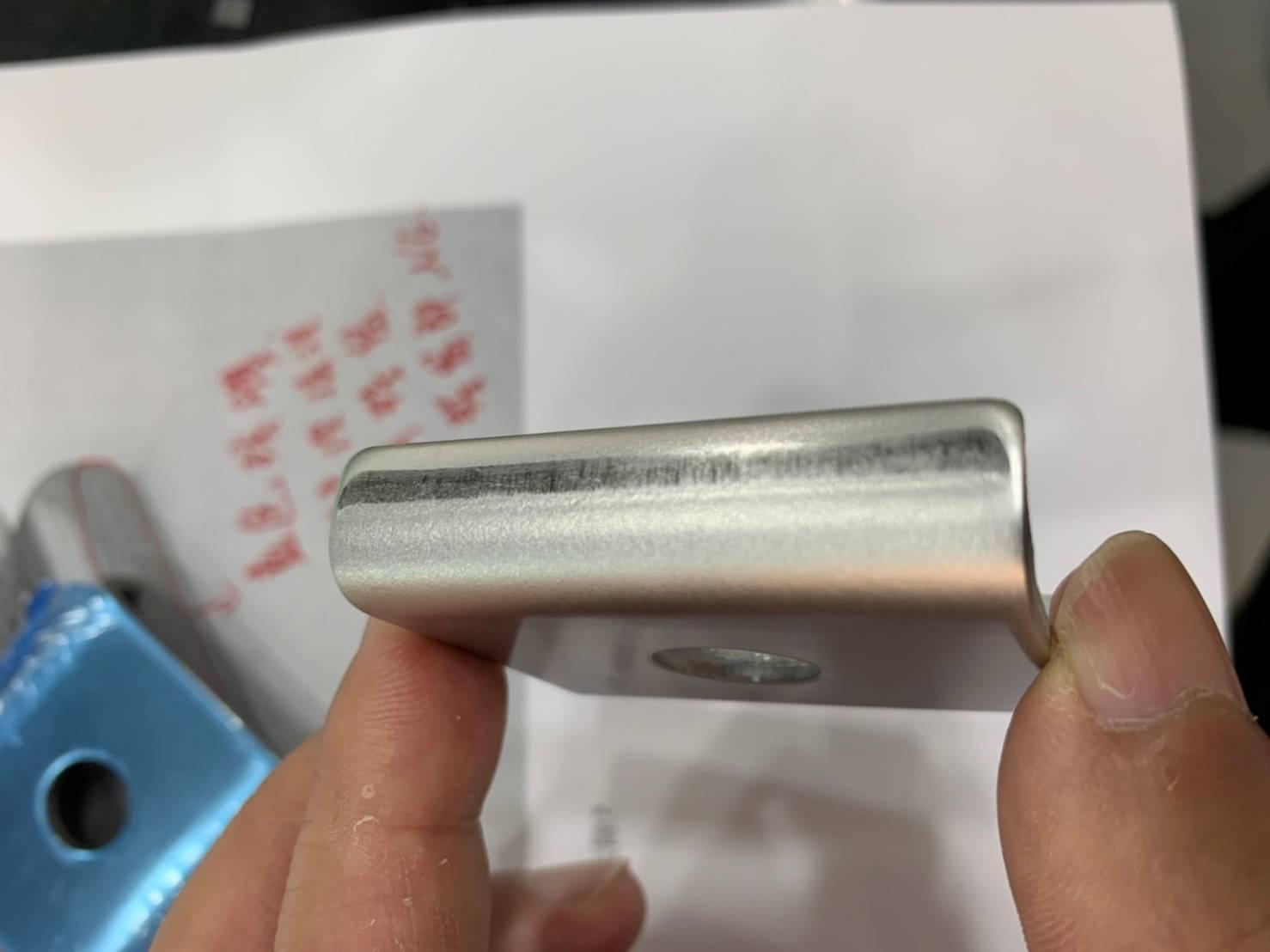

Repeat the test and take the third stainless steel Wafer Ring. The surface of this stainless steel Wafer Ring has circular scratches, and there is residual glue on the scratches. The picture below is before cleaning.

-

Wash with ultrasonic vibration for 5 minutes, take it out, and rinse with clean water. It is found that the residual glue and Particle on the surface have been completely removed. White spots under strong light are scratches.

-

Conclusions: 15.1 Heat the microdust cleaner PTC-3b to 60°C, and use an ultrasonic cleaning machine (40KHz, 50W/L) to vibrate and clean for more than 5 minutes, which can completely remove the particles and residual glue on the stainless steel Wafer Ring workpiece.

15.2 Ultrasonic cleaning machine (40KHz, 50W/L) vibration cleaning, must pay attention to power (50W/L), frequency (40KHz), workpieces cannot be stacked, and the distance between workpieces must be greater than 1/2λ (the speed of sound waves in water Divide by frequency 1600M/40000(40KHz)=4cm).

15.3 It is recommended to tear off the sticker before cleaning it with microdust cleaner PTC-3b.