1. Use microdust cleaner PTC04 (100%), heat to 45°C, and clean with 40KHz, 50W/2L ultrasonic wave for 5 minutes. Then rinse with pure water. It was found that the surface water marks could not be cleaned. Then heat it to 50°C with microdust cleaning agent PTC13, and clean it with 40KHz, 50W/2L ultrasonic wave for 5 minutes. After rinsing with pure water, it was found to be completely cleansed.

-

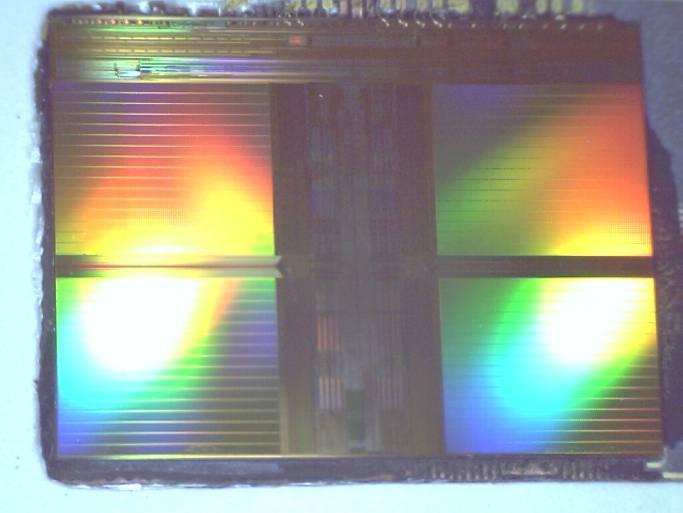

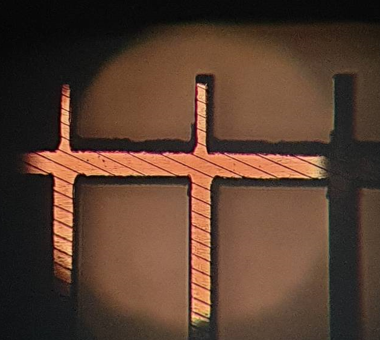

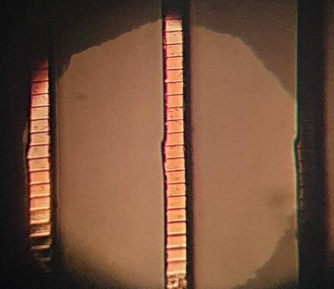

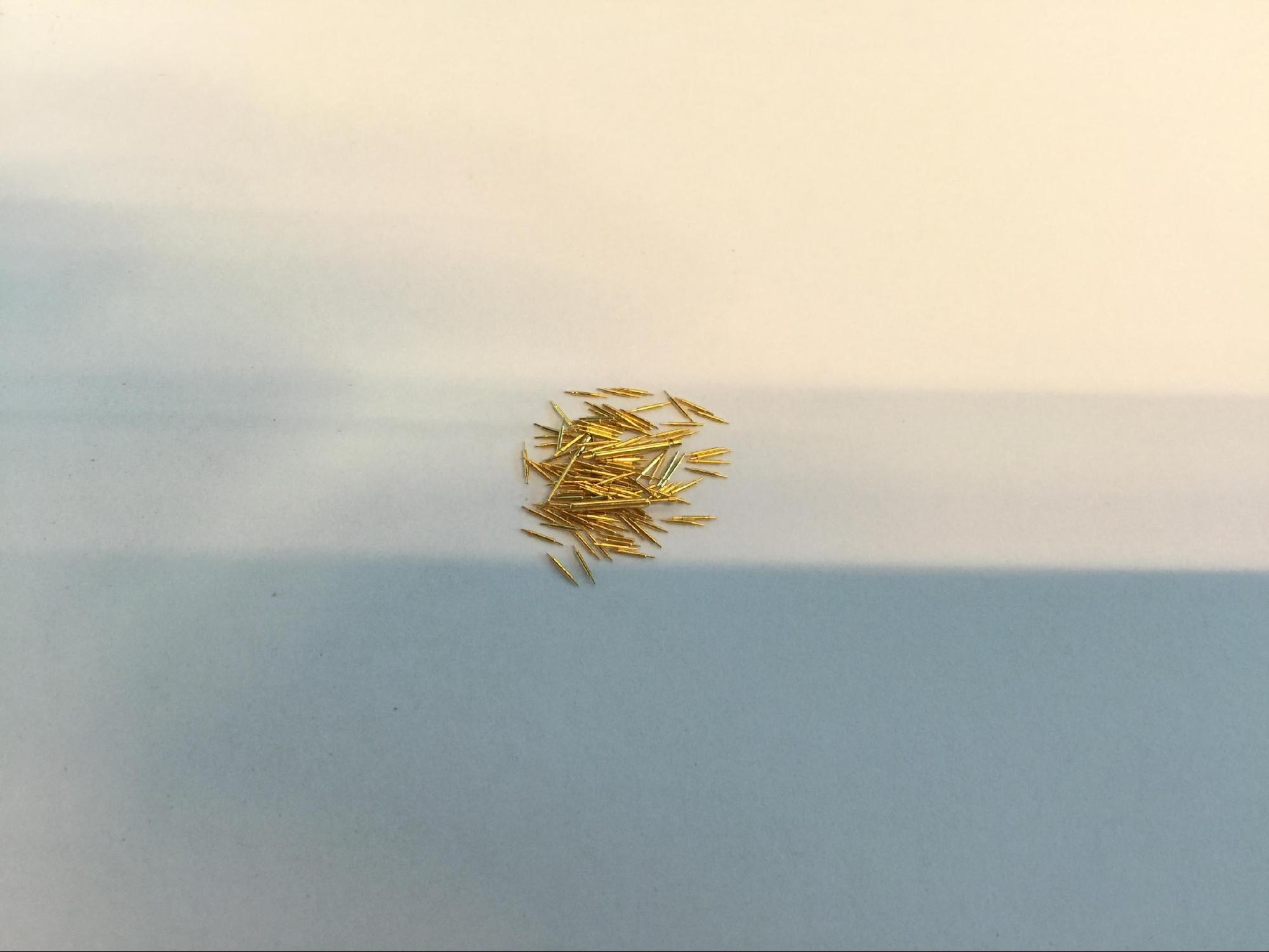

Before cleaning, because the surface is covered with particles, the existence of residual water marks cannot be seen with the naked eye.

-

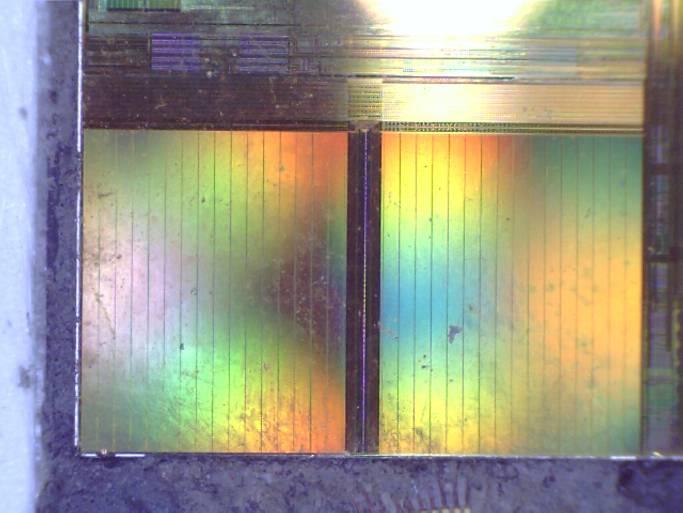

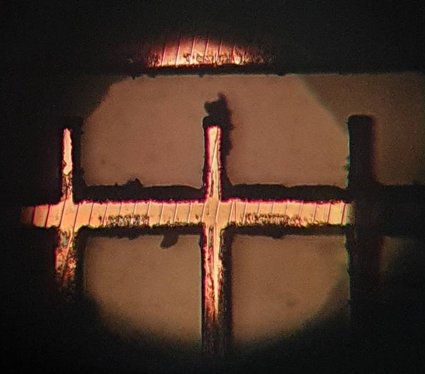

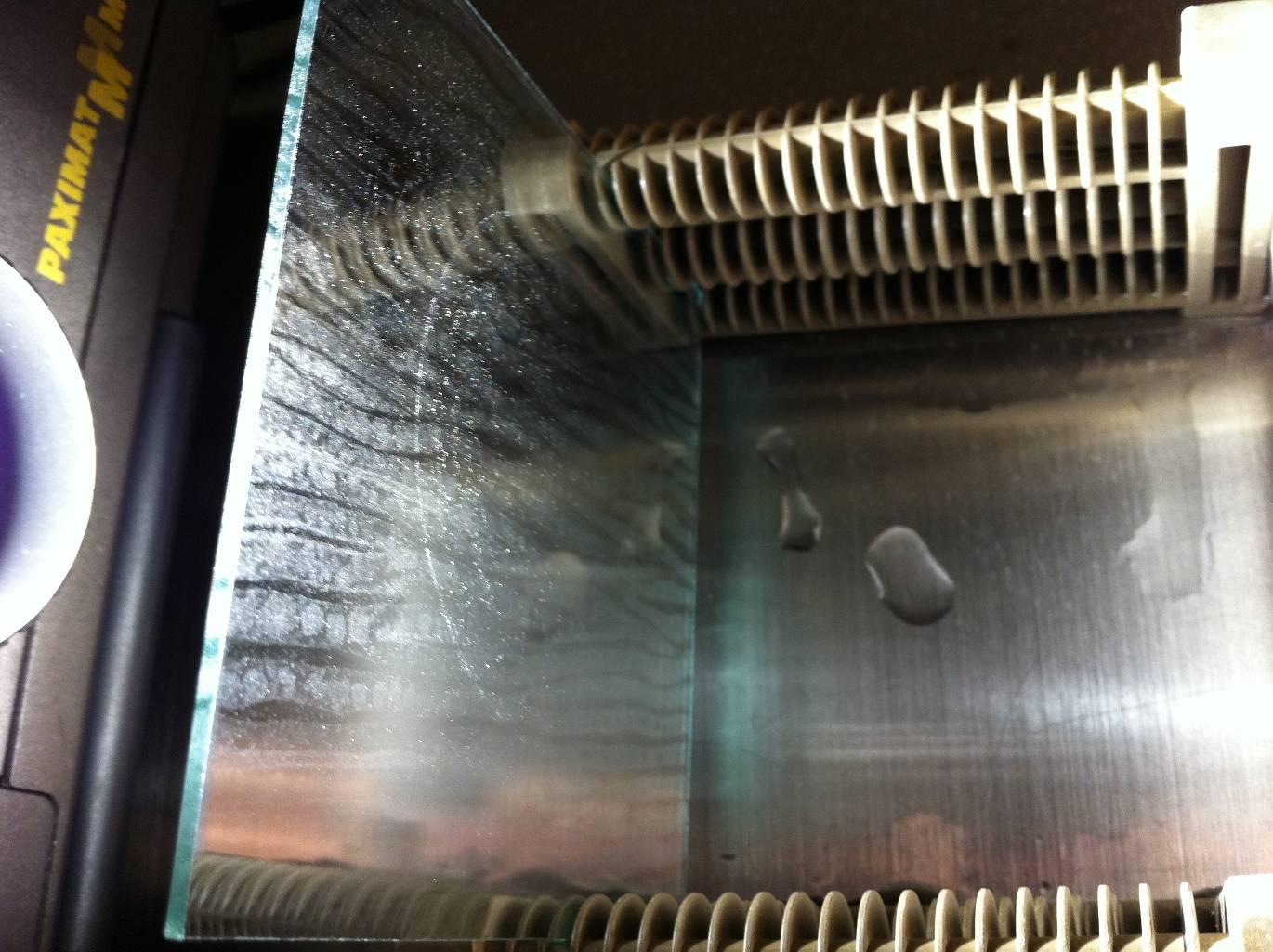

Put it in the dust cleaning agent PTC04 (100%), heat it to 45°C, and clean it with 40KHz, 50W/2L ultrasonic wave for 5 minutes. After rinsing with pure water, it was found that the surface was covered with water marks (or water mark-like coating). The original dirty shape has been improved, and water marks (or water mark-like coatings) can be seen more clearly.

-

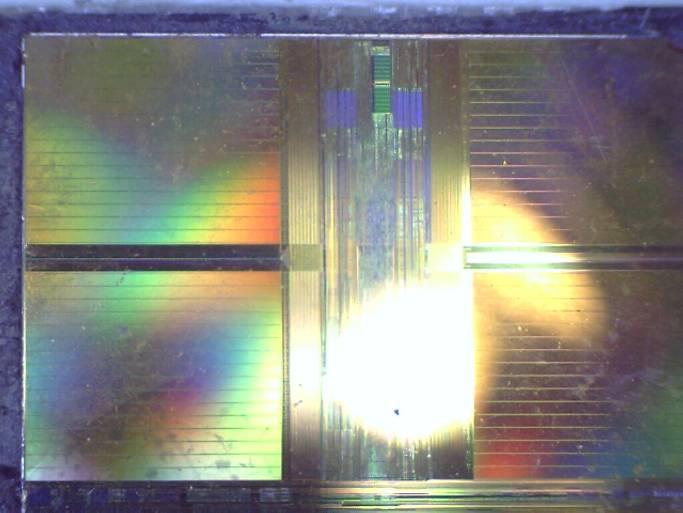

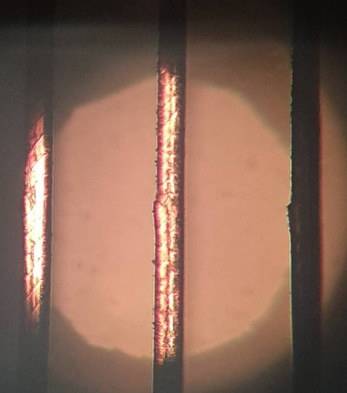

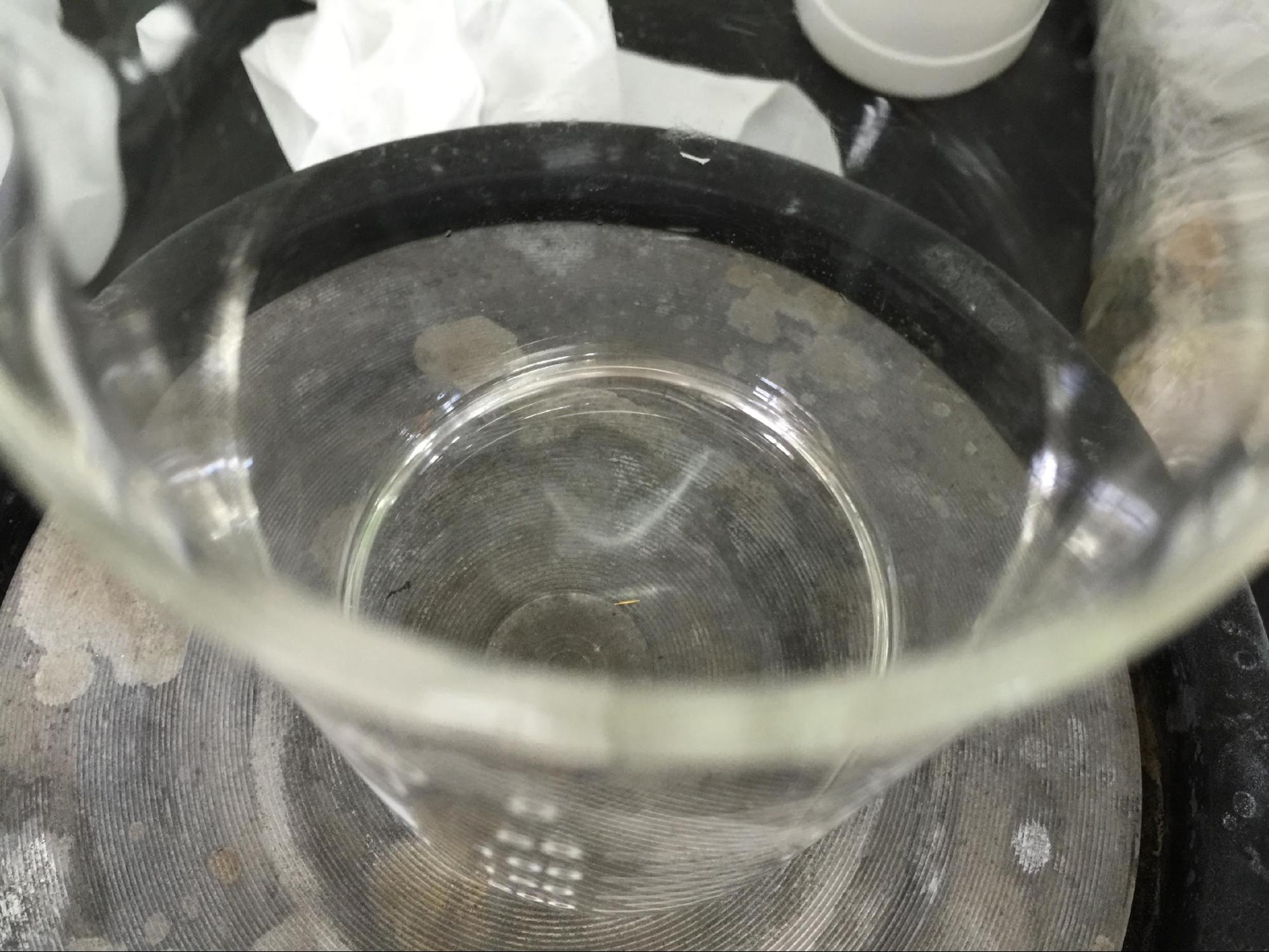

Take it out, and then heat it to 50°C with the dust cleaning agent PTC13, and clean it with 40KHz, 50W/2L ultrasonic wave for 5 minutes.

-

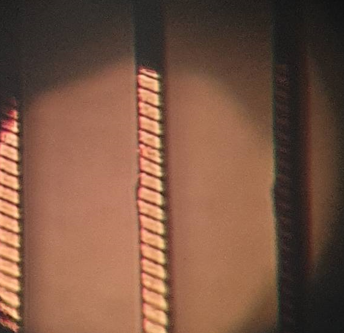

After rinsing with pure water, it was found to be completely cleansed.

-

Suggestions and discussions:

5.1 Microdust cleaner PTC04 cannot clean the water mark (or water mark-like coating) on this glass.

5.2 Use micro dust cleaning agent PTC13, heat to 50°C, and clean with 40KHz, 50W/2L ultrasonic wave for 5 minutes. Can be washed completely.

5.3 Microdust cleaning agent PTC13 can effectively clean organic polymer deposits, and can also decompose some inorganic films. And can generate interface potential (zeta potential) greater than -45mv. Make the glass surface and the particle form an effective repulsive negative voltage. It can effectively remove grease and particle pollution on the glass.