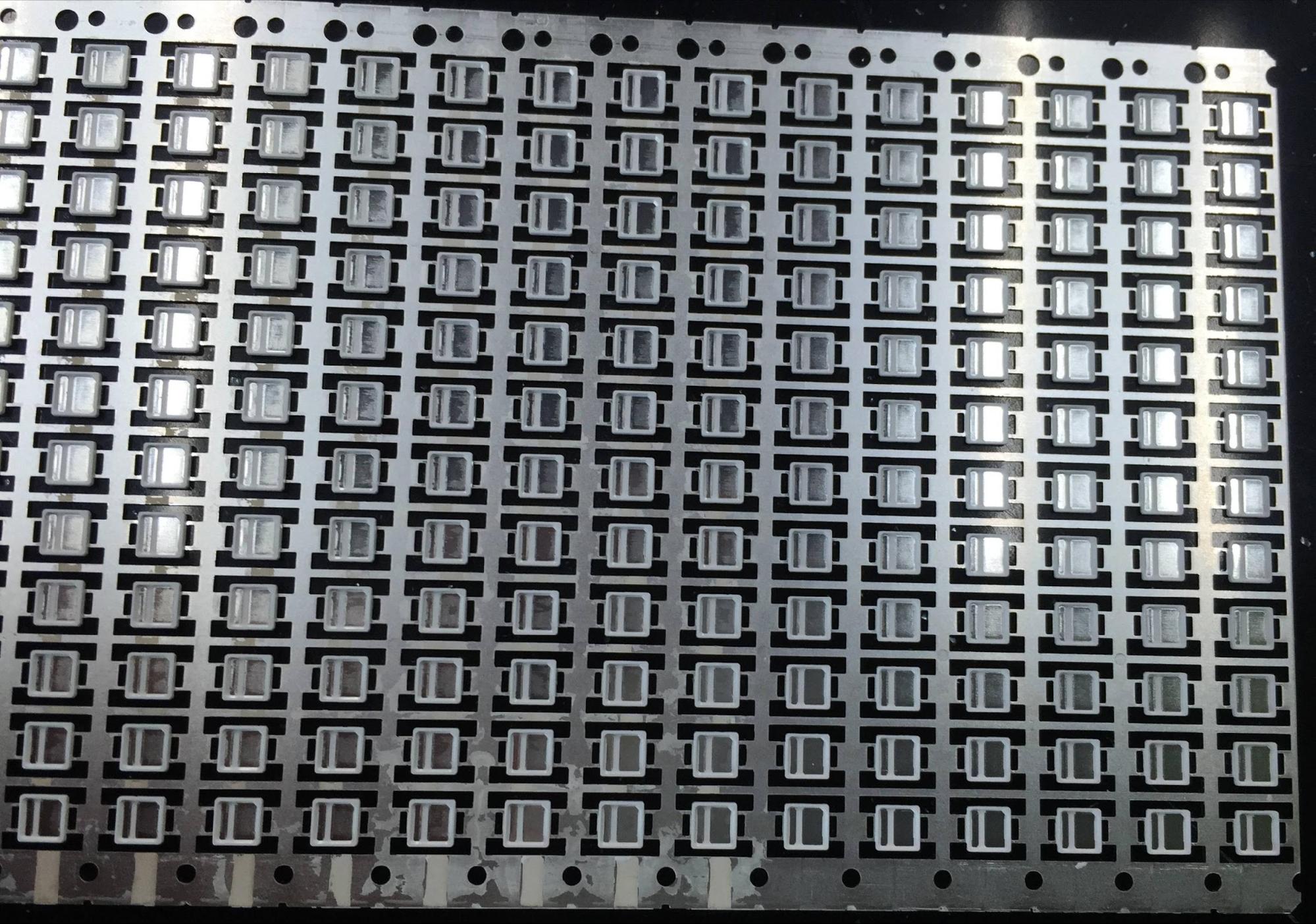

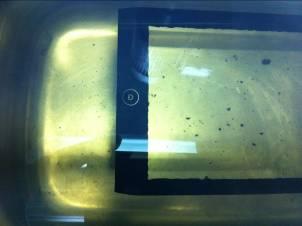

1. Use PTC13 (85% PTC13, 15% water), heat at 70°C, soak for 10 minutes, and peel off directly. Rinse off with pure water.

-

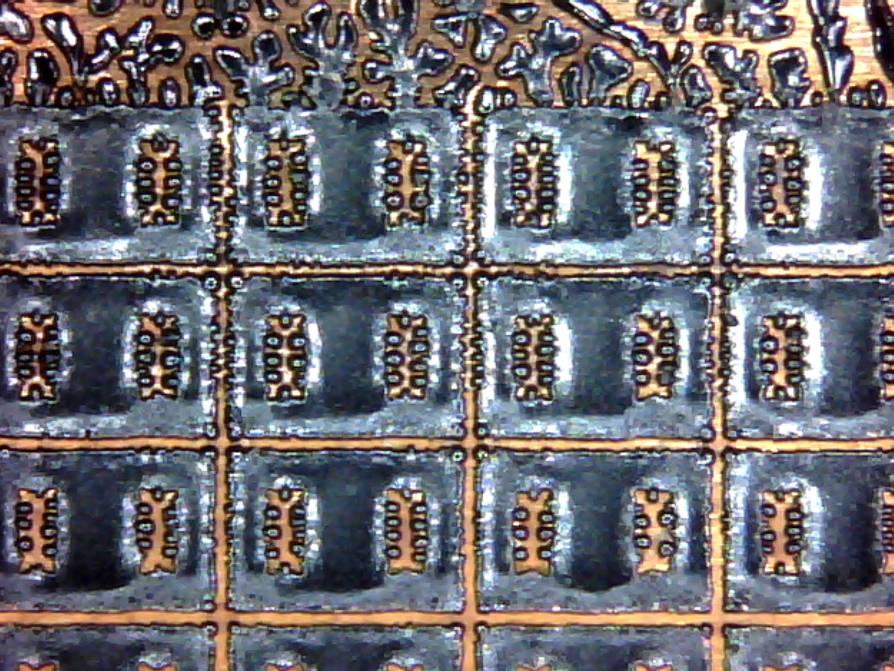

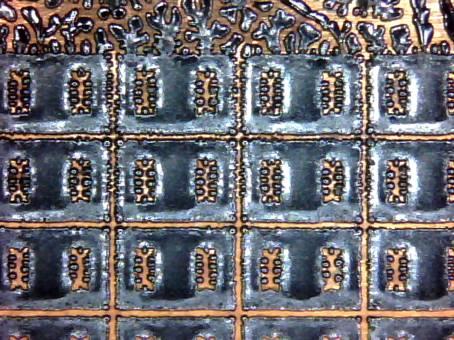

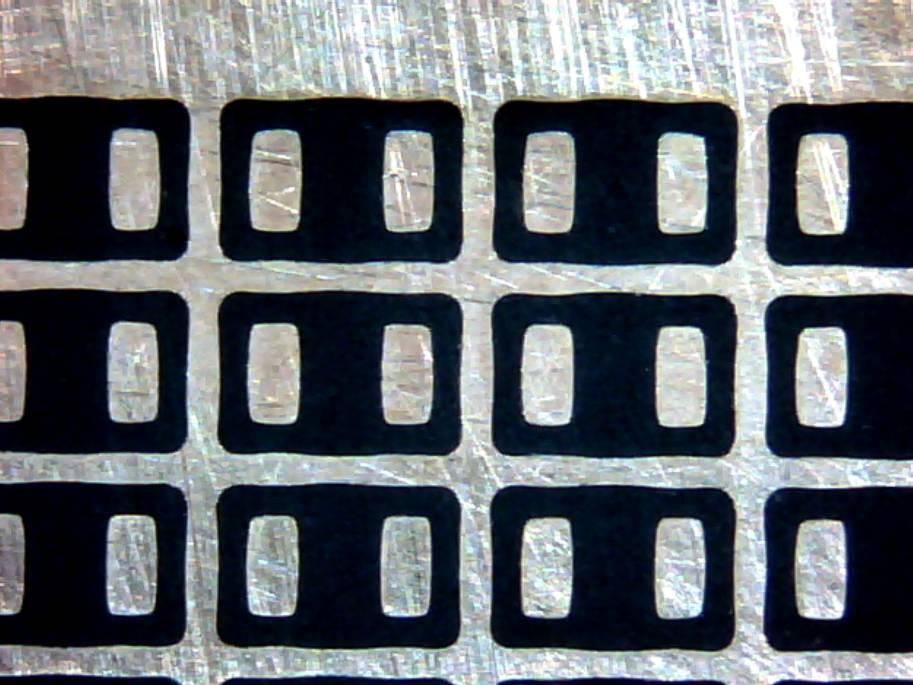

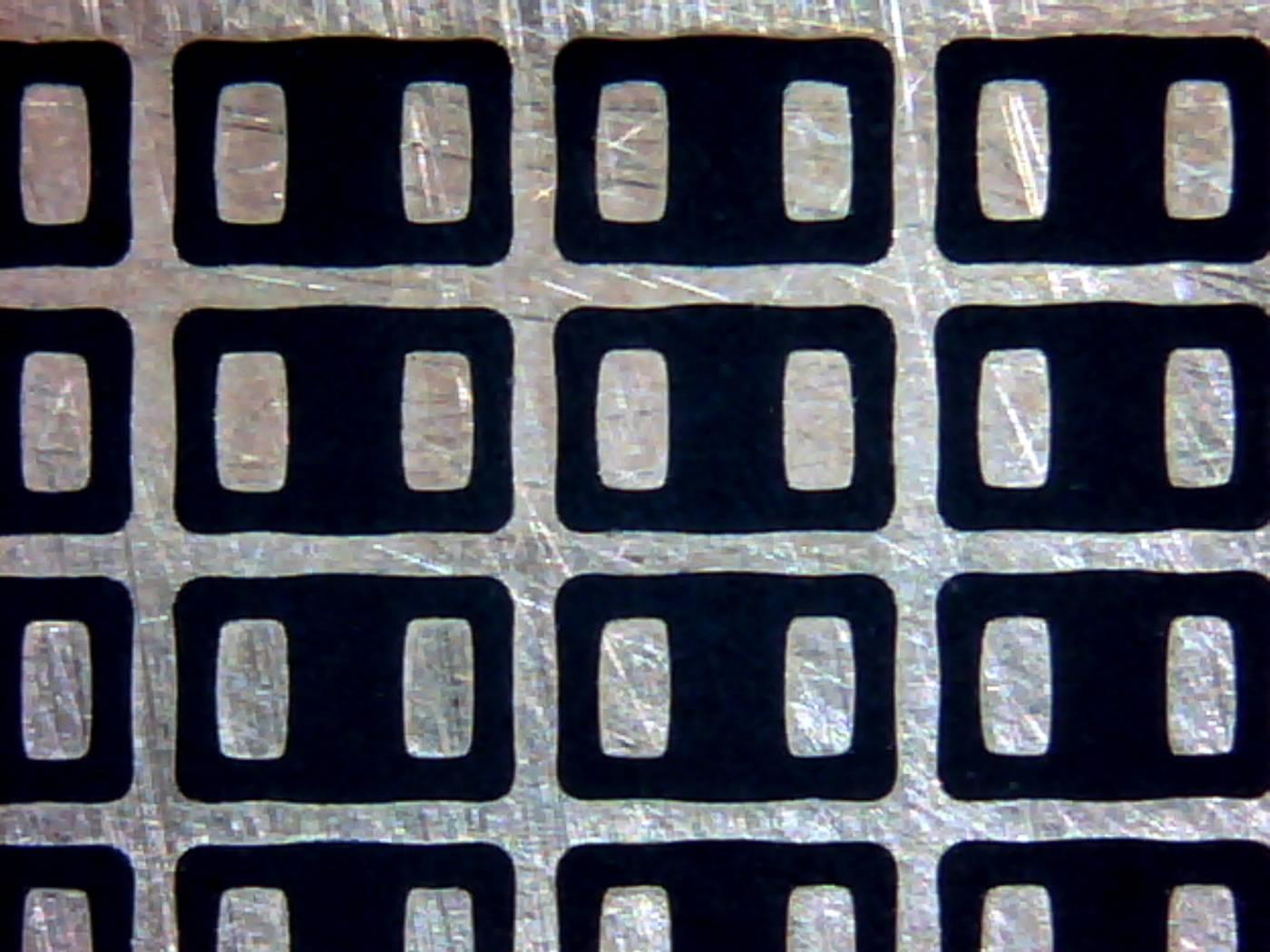

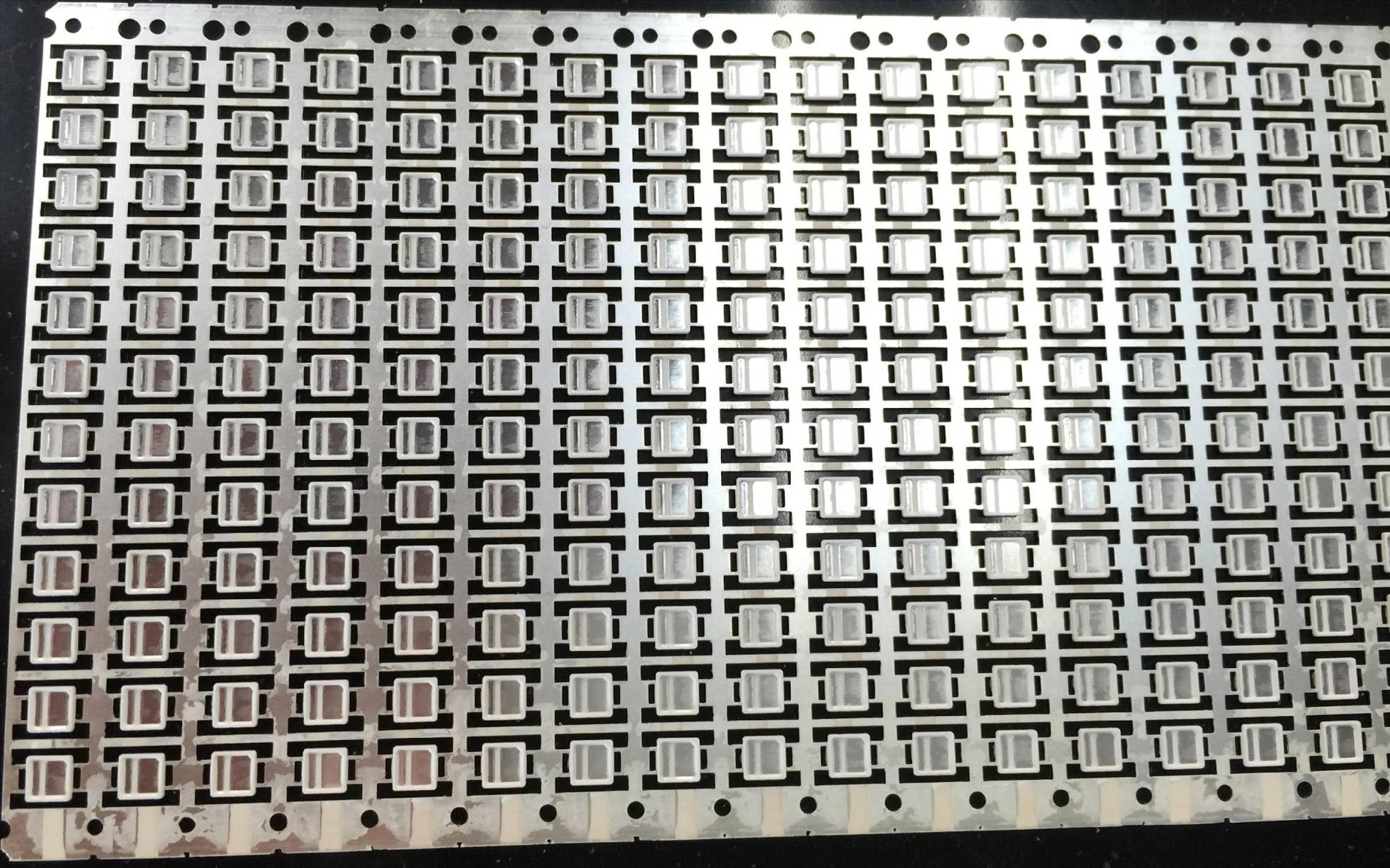

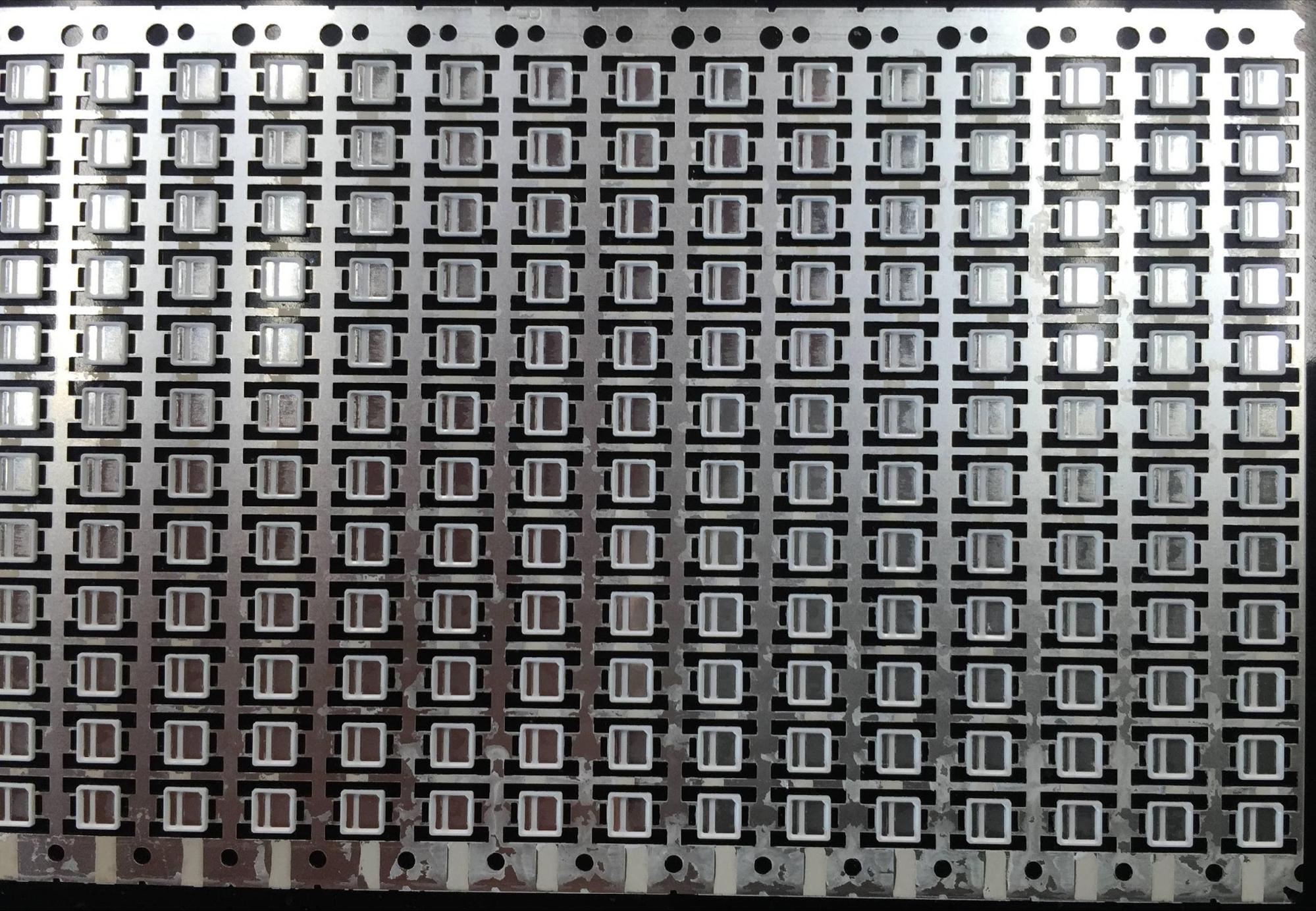

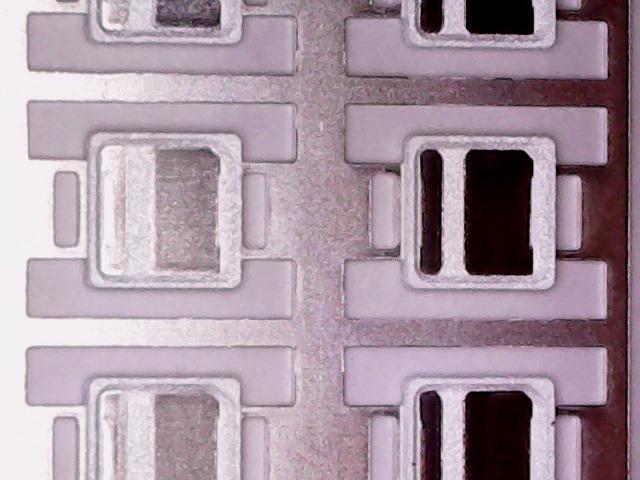

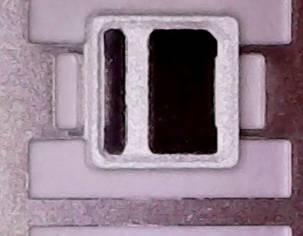

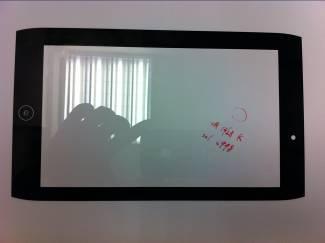

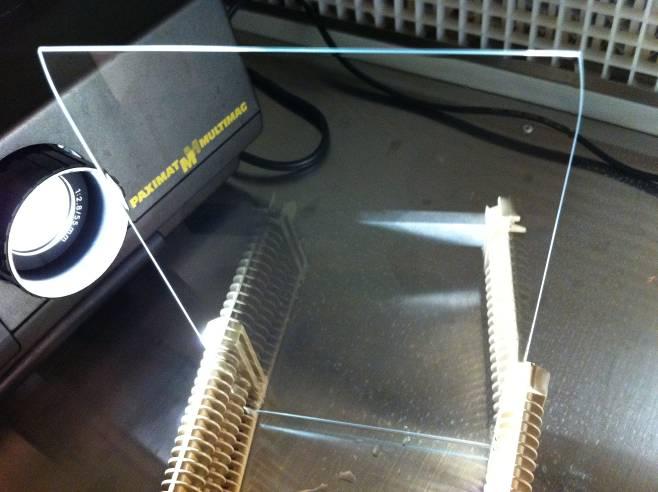

Before cleaning, it can be seen from the enlarged picture that it is three-dimensional glass with gaps.

-

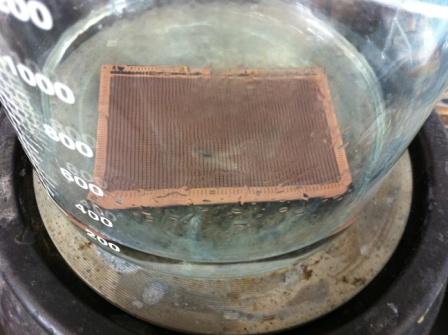

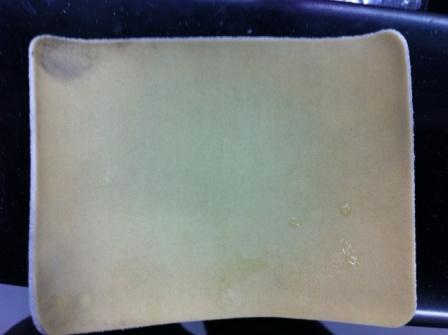

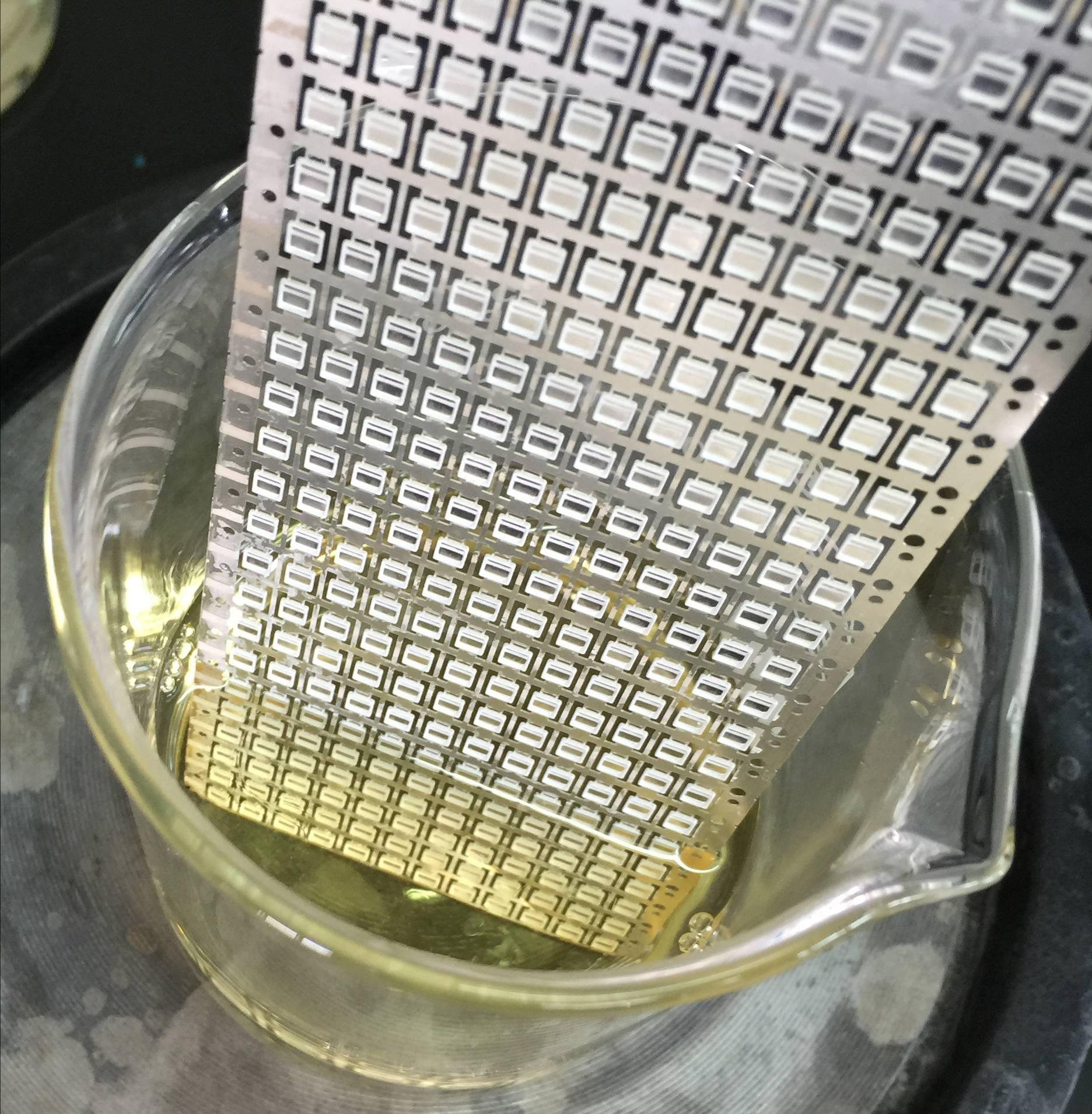

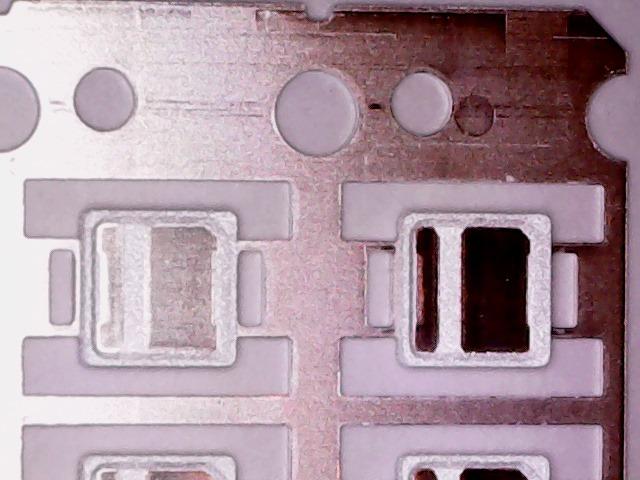

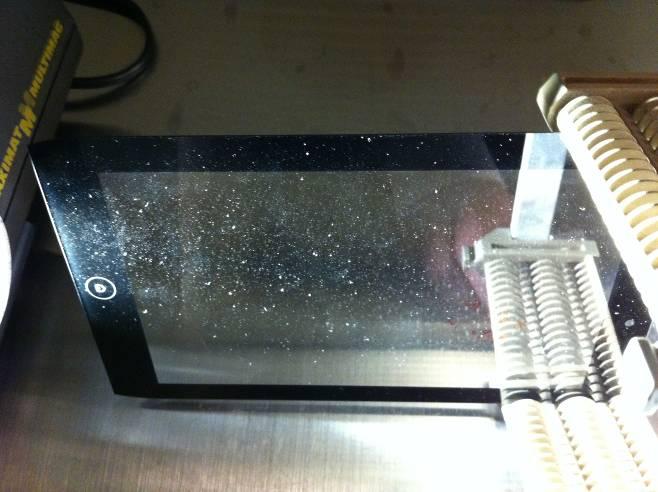

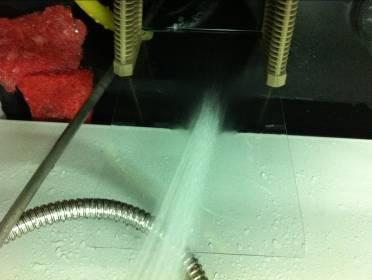

Place in PTC13 (85% PTC13, 15% water) at 70°C, heat and soak for 10 minutes.

-

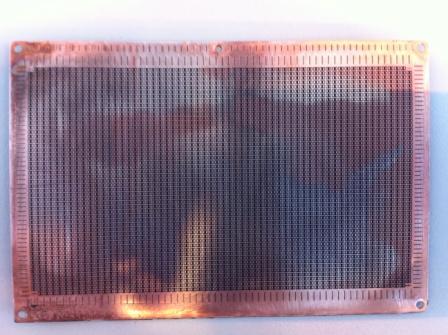

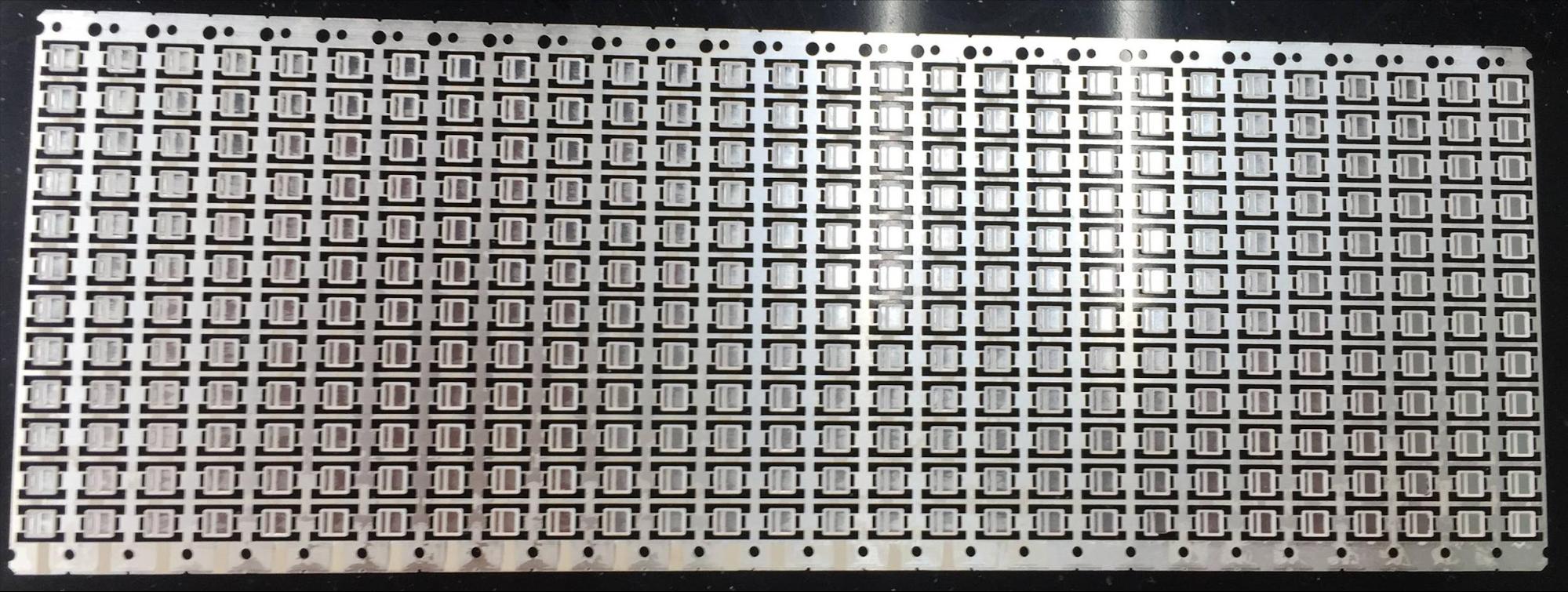

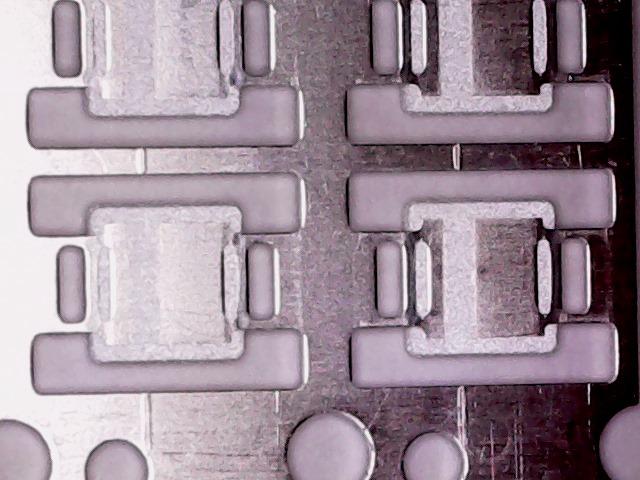

Watch on the desktop

-

Suggestions and discussions:

4.1 PTC13 confirms that the hardened black frame ink on the provided CG samples can be effectively peeled off.

4.2 Placed at 70°C, heated and soaked for 10 minutes is a preliminary test condition, not the best parameter. It is recommended that process engineers need to reconfirm the corresponding parameters of time and temperature in order to find the shortest time and optimum temperature.

4.3 Automation suggested process:

4.3.1 Soaking tank. Soak at 70°C PTC13 for 5-10 minutes. Swell and peel hardened ink.

4.3.2 Rinsing tank. According to the appropriate cleaning design, it is divided into 3~6 washing and drying.

4.4PTC13 can generate a zeta potential greater than -45mv. Make the glass surface and the particle form an effective repulsive negative voltage. While peeling off the hardened ink on the glass, it can also effectively remove grease and particle pollution on the glass.