-

PMMA and wafers sent by customers before cleaning. Under the strong light in the clean room, it was found that the surface of the visible area was covered with foggy particles.

-

Place in 100% PTC17plus, 40KHz ultrasonic wave, 30W/L, room temperature, shake and wash for 1 minute.

-

Take out the flush water and observe under the strong light in the clean room. It is found that the particle has been completely cleared.

-

Repeat the test. Take another lens, before cleaning, the surface still has particles attached, but the fog in the viewing area is lighter.

-

Place in 100% PTC17plus, 40KHz ultrasonic wave, 30W/L, room temperature, shake and wash for 2 minutes. Take out the flush water and observe under the strong light in the clean room. It is found that the particle has been completely cleared.

-

Since there are still drops of water on the surface of the cleaning parts, put them in a clean room and let them dry. After drying, confirm that the water droplets in the visible area have evaporated and are completely washed.

-

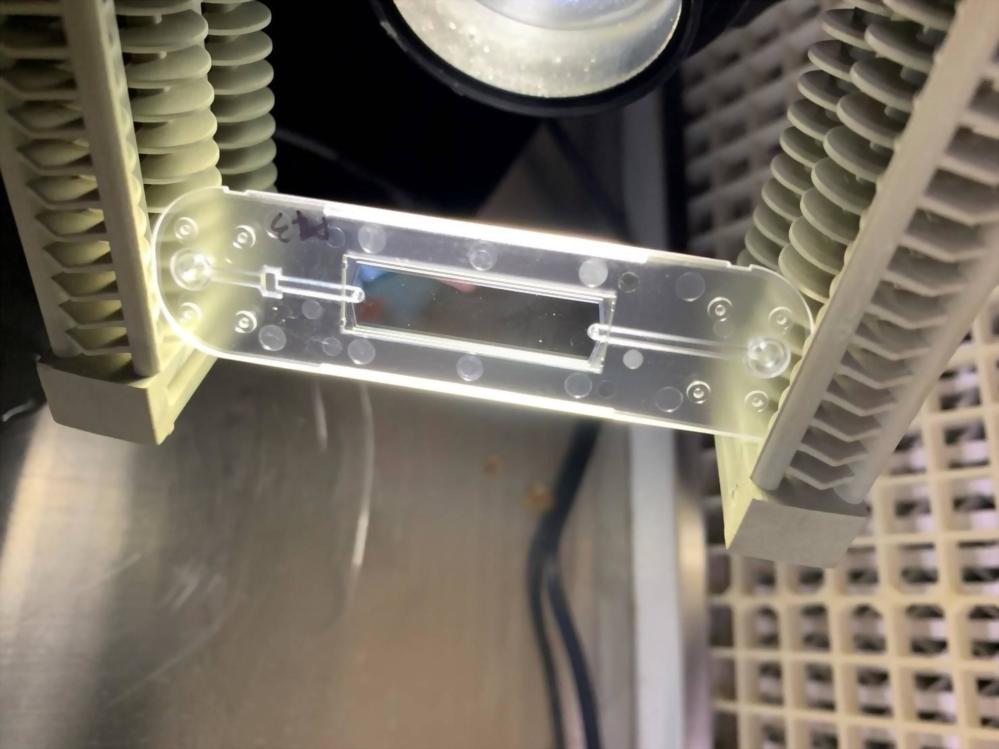

Test wafer cleaning. Before cleaning the sent wafer, it can be seen that the surface is covered with particles under strong light.

-

Wash with 100% PTC17plus, 40KHz ultrasonic wave, 30W/L, room temperature, and shake for 2 minutes. Take out the flush water and observe under the strong light in the clean room. It is found that although some particles have been removed, there are still many particles remaining.

-

Extend cleaning time. With 100% PTC17plus, 40KHz ultrasonic wave, 30W/L, room temperature, shake and clean again for 10 minutes. Take out the flush water and observe under the strong light in the clean room. It was found that the residual particles had been removed. However, after drying in the clean room, it was found that there were water marks on the bottom. It was suspected that the cleaning agent was not completely rinsed, and after the rinse water flowed down, the dry residue remained.

-

Extend the pure water rinse time. Because the customer indicated that the center of the wafer is full of holes. Consider the extremely slow flow of liquid in a hole. Therefore, wash again with 100% PTC17plus, 40KHz ultrasonic wave, 30W/L, room temperature for 1 minute, and then rinse with pure water for 20 minutes. Found to be completely clean.

-

conclusion and suggestion:

11.1 PTC17plus can effectively clean PMMA plastic lenses and wafers. For related parameters, please refer to the above report.

11.2 100% PTC17plus can effectively clean PMMA plastic lenses and wafers. Customers are asked to repeatedly verify the cleaning effect by themselves, and adjust the parameters by themselves, reduce the concentration, increase the temperature, prolong or shorten the cleaning time...etc.

11.3 PMMA plastic lenses and wafers are fixed in fixtures and placed in an ultrasonic cleaning machine for cleaning. Please note that the interval must be greater than 1/2λ. (Converted at 40KHz, 1/2λ is about 2 cm, and the recommended distance is more than 3 cm)

11.4 Please note that the agent or water flows through the center of the wafer filled with holes, and the flow rate will be slower when approaching the surface. Therefore, it is necessary to increase the temperature or increase the rinse time to completely remove the agent and particles.