-

The lens material is S-BSM14. According to the information provided by the customer, the material is soft and not resistant to strong alkali; therefore, a special degreasing agent "C8" for low alkalinity optical polishing was developed. Degreasing agent "C8" for optical polishing has a pH of 11.0. Before cleaning, a large amount of centering oil is attached to the surface.

-

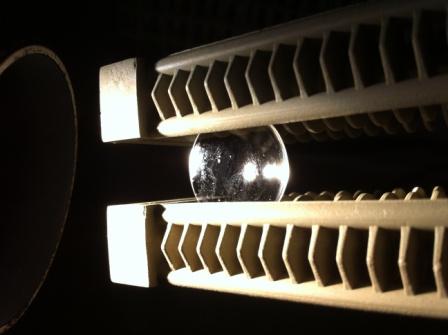

Place in 100% C8, 45°C, 40KHz ultrasonic wave, 30W/L, and shake for 3 minutes. It was found that the dirt was completely washed away. And the lens is not damaged; the surface does not have any fine lines.

Observing from different angles, it is found that the cleanliness is good, no matter what angle you use, there is no trace.

-

Take another lens and repeat the test. Before cleaning, a large amount of centering oil is also attached to the surface.

-

Continue to place in 100% C8, 45°C, 40KHz ultrasonic wave, 30W/L, and shake for 3 minutes. It was found that the dirt was completely washed away. And the lens is not damaged; the surface does not have any fine lines.

-

Increase the cleaning temperature to 55°C and repeat the test. Take another piece of lens, and before cleaning, there is still a lot of centering oil attached to the surface.

-

Place in 100% C8, 55°C, 40KHz ultrasonic wave, 30W/L, and shake for 3 minutes. It was found that the dirt was completely washed away. And the lens is not damaged; the surface does not have any fine lines.

-

Extend the wash time to 6 minutes and repeat the test. Take another piece of lens, and before cleaning, there is still a lot of centering oil attached to the surface.

-

Place in 100% C8, 45°C, 40KHz ultrasonic wave, 30W/L, and shake for 6 minutes. It was found that the dirt was completely washed away. And the lens is not damaged; the surface does not have any fine lines.

-

Lower the cleaning temperature to room temperature (20°C) and repeat the test. Take another piece of lens, and before cleaning, there is still a lot of centering oil attached to the surface.

-

Place in 100% C8, room temperature (20°C), 40KHz ultrasonic wave, 30W/L, and shake for 6 minutes. It was found that the dirt was not completely washed.

-

Suggestions and discussions:

11.1 Place in 100% C8, 45°C, 40KHz ultrasonic, 30W/L, and shake for 3 minutes. It was found that the dirt was completely washed away. And the lens is not damaged; the surface does not have any fine lines. C8 is an agent suitable for cleaning the centering oil on the surface of S-BSM14 lens.

11.2 The special degreasing agent C8 for optical grinding contains long carbon chain surfactant components. Although it has good degreasing power, the long carbon chain surfactant is not easy to rinse and clean. The post-cleaning rinse in this test report is to rinse with a large amount of pure water for more than 5 minutes, in order to no longer see the bubble residue on the fixture. It is recommended that in the mass production process, the special degreasing agent C8 for optical polishing should be placed in the front-end cleaning (replacing aromatic solvents such as DC-14), and the back-end should be equipped with a short carbon chain and low alkalinity dust cleaning agent, such as PTC06L, to Efficiently rinses clean.

11.3 Since the special degreasing agent C8 for optical grinding is a low-alkalinity lotion, its damage to the lens of the S-BSM14 soft material is not as strong as that of the high-alkaline agent SILILON-HS, so it is recommended that the cleaning temperature can be increased to 40~45°C. The cleanliness of cleaning at room temperature is not as good as that at 45°C.