1. Use SGC01 (95%, 5% water), heat at 75°C and soak for 10 minutes. Then wipe off with a lint-free cloth.

-

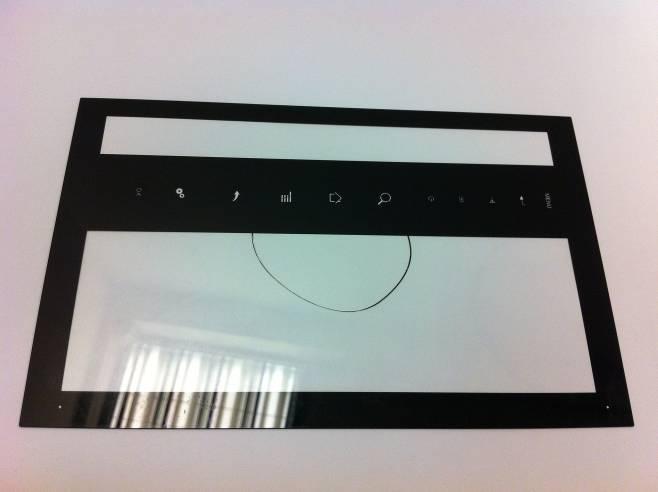

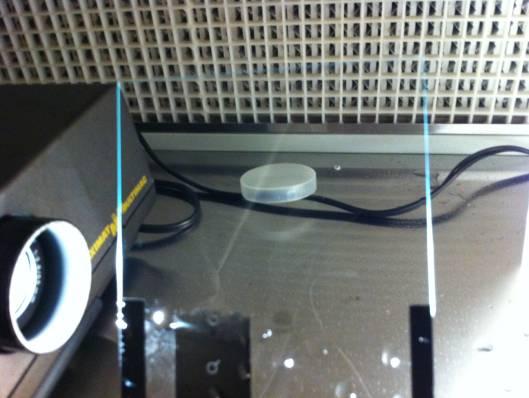

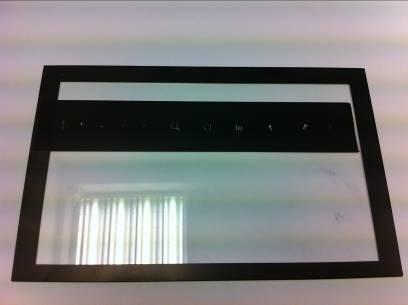

before cleaning

-

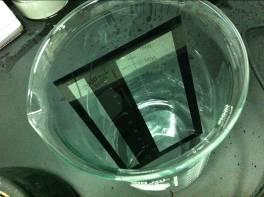

Place in SGC01 (95%, 5% water) at 75°C, heat and soak for 10 minutes.

-

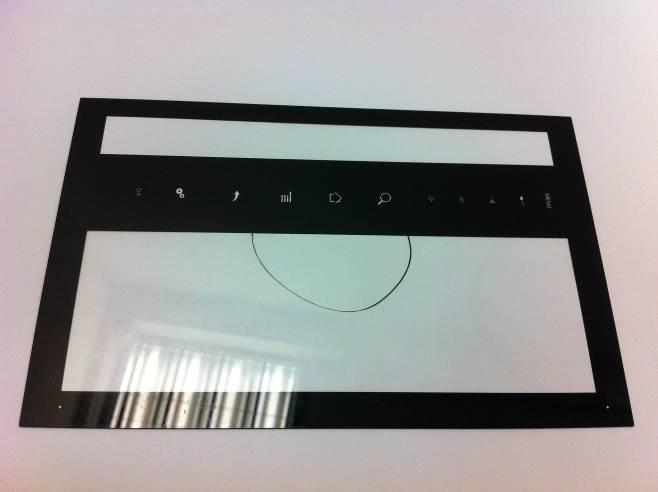

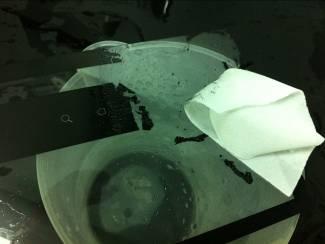

The ink in the middle of the glass peeled off significantly after soaking for 10 minutes.

Soak for 1 minute

Soak for 10 minutes

-

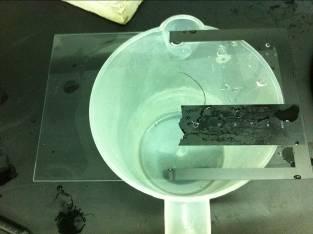

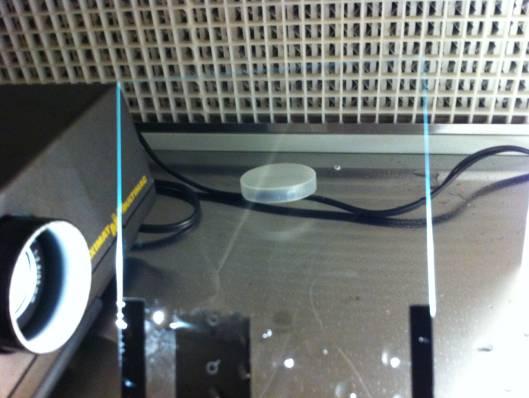

The ink on the four sides of the glass still does not peel off after soaking in SGC01 for 30 minutes. But take it out and wipe it with a lint-free cloth, it can be easily wiped off. There is a small amount of ink residue, which can be completely removed after soaking SGC01 for 10 minutes again.

-

Suggestions and discussions:

5.1 SGC01 confirms that the CG sample provided to IDEETech can effectively peel off the hardened black frame ink on it.

5.2 Since the ink on the four sides of the glass does not swell and peel off, it is impossible to determine whether it can be removed with a dust-free cloth after soaking for 30 minutes. It is recommended that process engineers need to reconfirm the corresponding parameters of time and temperature.

5.3 Automation suggested process:

5.3.1 Prewash tank. Pre-wash with ultrasonic wave at 60℃, SGC01 for 1 minute. Wash off the particles on it to avoid scratches on the glass when the rear plum page scrubber is scrubbing.

5.3.2 Soaking tank. Soak for 10 (~30) minutes at 75°C SGC01. Decomposes and softens hardened ink.

5.3.3 Scrub tank. Scrub with plum-type brushing machine to wash off the ink.

5.3.4 Re-soak tank. Soak for 10 minutes at 75°C SGC01. This step is to confirm that the hardened ink that may not have come off completely in the previous step due to too much thickness can be decomposed and softened again.

5.3.5 Scrub tank. Scrub with plum-type brushing machine to remove all ink, pollutants and particles on the glass.

5.3.6 Washing tank. According to the design of plum-page brush washing machine, it is divided into 3~6 steps of washing and drying.

5.4SGC01 can generate a zeta potential greater than -36mv. Make the glass surface and the particle form an effective repulsive negative voltage. While peeling off the hardened ink on the glass, it can also effectively remove grease and particle pollution on the glass.

2. Use SGC04 (85% SGC04, 15% water), heat at 70°C and soak for 10 minutes. Then wipe off with a lint-free cloth.

-

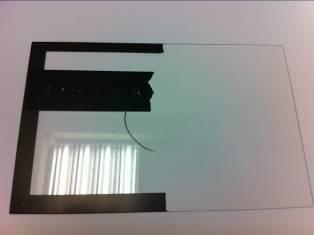

Before cleaning (applied to Sensor deglue)

-

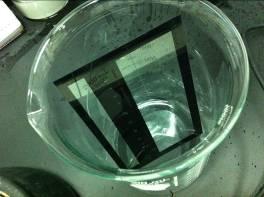

Place in SGC04 (85% SGC04, 15% water) at 70°C, heat and soak for 10 minutes.

-

The ink in the middle of the glass peeled off significantly after soaking for 6 minutes.

Soak for 1 minute

Soak for 6 minutes

-

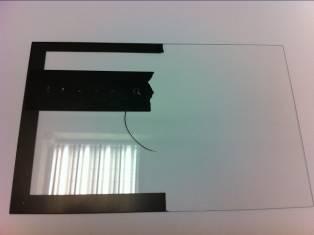

The ink on the four sides of the glass still does not peel off after soaking SGC04 for 10 minutes. But take it out and wipe it with a lint-free cloth, it can be easily wiped off.

-

There is still a small amount of ink residue on the glass, which can be completely removed after soaking SGC04 again for 5 minutes.

-

In a dust-free dark room, observe with a strong light to confirm that the black frame ink and particles can be completely removed.

-

Suggestions and discussions:

7.1 SGC04 confirms that the CG sample provided to IDEETech can effectively remove the hardened black frame ink on it.

7.2 Since the ink on the four sides of the glass does not swell and peel off, it is impossible to determine whether it can be removed by wiping with a clean cloth within 10 minutes of soaking. It is recommended that process engineers need to reconfirm the corresponding parameters of time and temperature.

7.3 Automated suggested process:

7.3.1 Prewash tank. Pre-wash with ultrasound at 60°C SGC04 for 1 minute. Wash off the particles on it to avoid scratches on the glass when the rear plum page scrubber is scrubbing.

7.3.2 Soaking tank. Soak for 7 (~10) minutes at 70°C SGC04. Decomposes and softens hardened ink.

7.3.3 Scrub tank. Scrub with plum-type brushing machine to wash off the ink.

7.3.4 Re-soak tank. Soak for 5 minutes at 70°C SGC04. This step is to confirm that the hardened ink that may not have come off completely in the previous step due to too much thickness can be decomposed and softened again.

7.3.5 Scrub tank. Scrub with plum-type brushing machine to remove all ink, pollutants and particles on the glass.

7.3.6 Washing tank. According to the design of plum-page brush washing machine, it is divided into 3~6 steps of washing and drying.

7.4 SGC04 can generate a zeta potential greater than -45mv. Make the glass surface and the particle form an effective repulsive negative voltage. While peeling off the hardened ink on the glass, it can also effectively remove grease and particle pollution on the glass.