-

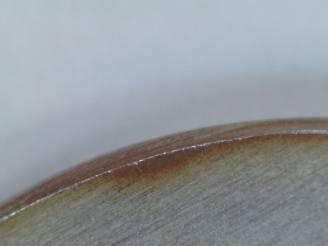

Before cleaning, the scorch marks left by laser cutting can be clearly seen.

Zoom in to see:

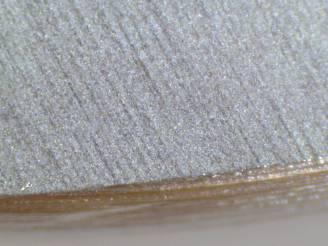

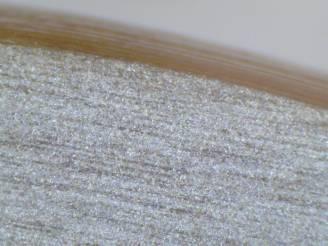

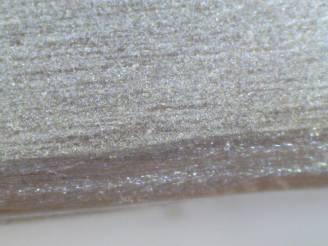

Observe with a microscope:

-

Put the workpiece into the silicon dioxide film cleaner SMC04 at 60°C and the stainless steel bright passivator A2yD at 70°C.

The left side of the photo is SMC04, which must be stored in a plastic beaker and heated over water; the right side is A2yD.

-

It was found that immersion in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds can effectively remove the burn marks left by laser cutting.

-

Soak in stainless steel bright passivator A2yD at 70°C for 30 minutes; it was found that it can also remove the burn marks left by laser cutting. But there are still a small amount of traces that cannot be completely removed.

-

Soak in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds, and then soak in stainless steel bright passivator A2yD at 70°C for 3 minutes; it can effectively remove the burn marks left by laser cutting. And the stainless steel workpiece is brighter.

-

Take another workpiece and repeat the test. Soaking in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds can effectively remove the scorched marks left by laser cutting. The left side of the photo below is soaked SMC04, 60 ℃, 30 seconds; the right side is not soaked.

-

Take another workpiece and repeat the test. Soak in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds, and then soak in stainless steel bright passivator A2yD at 70°C for 3 minutes; it is found that it can effectively remove the scorch marks left by laser cutting. The right side of the photo below is soaked; the left side is unsoaked.

-

However, there is no significant difference compared with simply soaking SMC04 at 60°C for 30 seconds. The left side of the photo below is soaking SMC04 at 60°C for 30 seconds; the right side is soaking SMC04 at 60°C for 30 seconds, then soaking at 70°C for 3 minutes at A2yD.

-

in conclusion:

9.1 Soak in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds, which can effectively remove the scorch marks left by laser cutting.

9.2 The cleaning effect of stainless steel bright light passivator A2yD is poor.

9.3 Soak in silicon dioxide film cleaner SMC04 at 60°C for 30 seconds, and then soak in stainless steel bright passivator A2yD at 70°C for 3 minutes; it is found that it can effectively remove the scorch marks left by laser cutting, and can effectively avoid stainless steel workpieces rust.