-

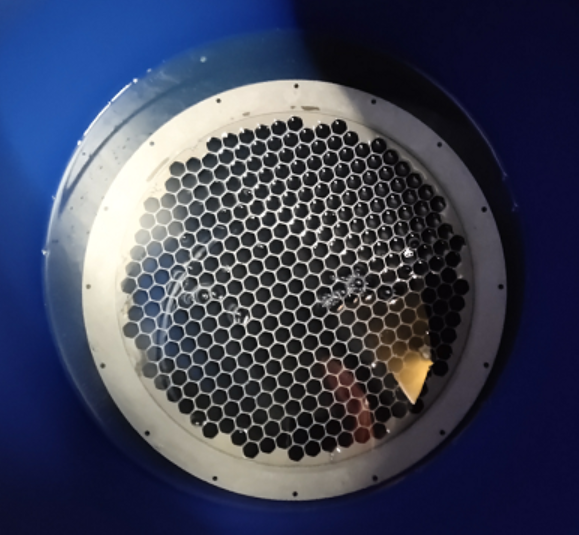

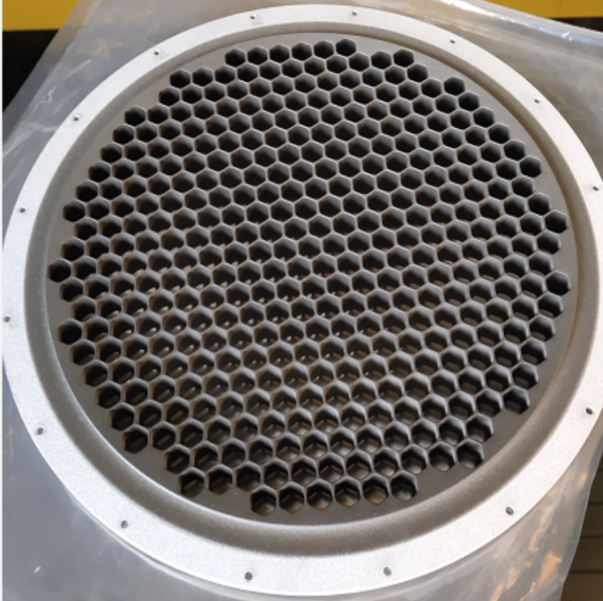

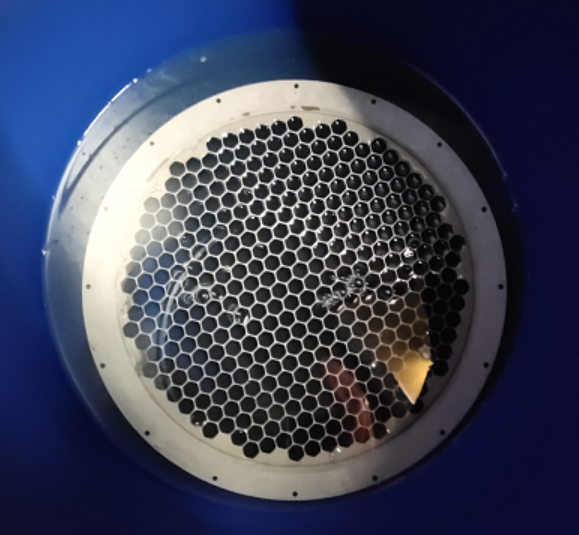

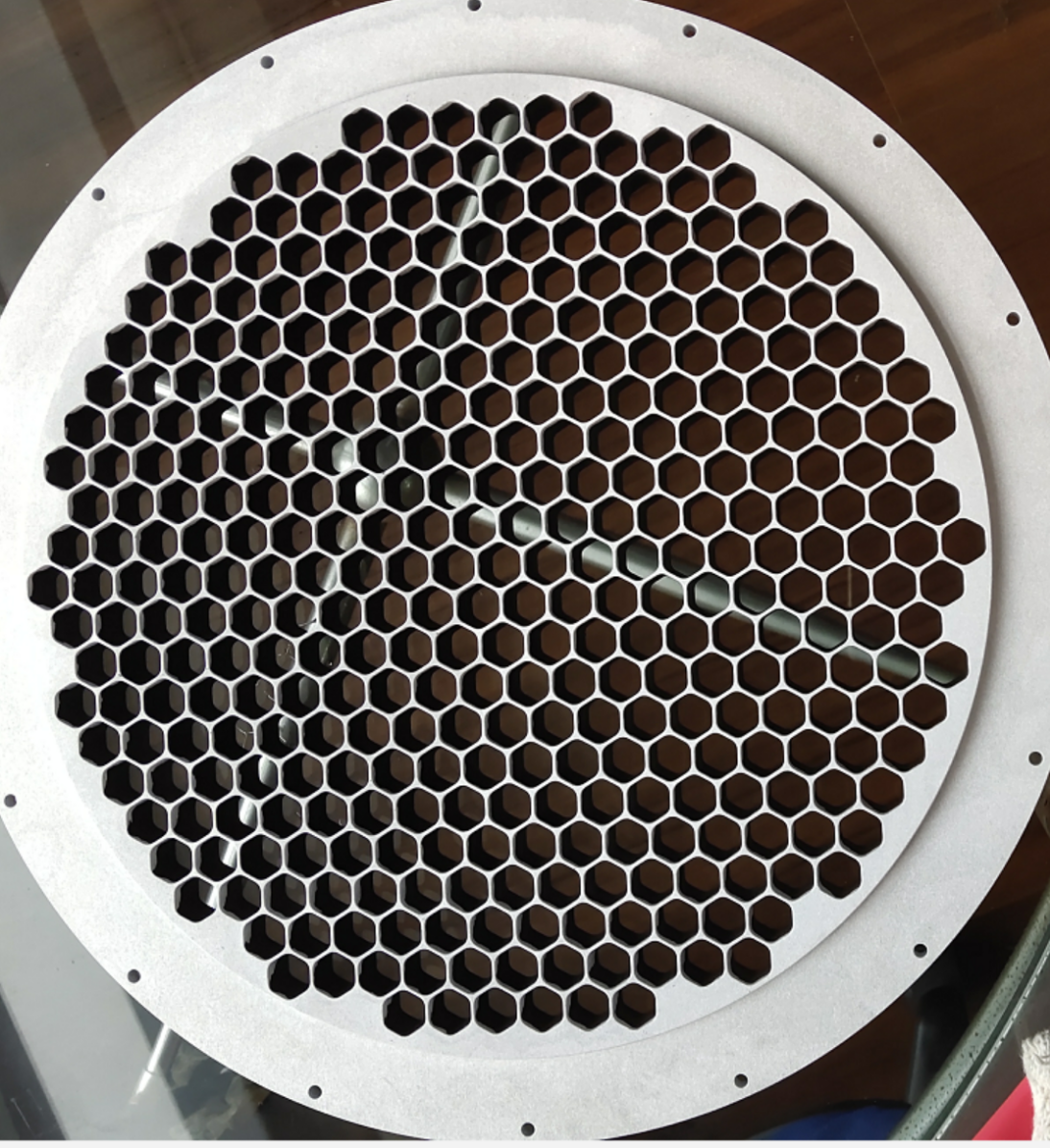

The Collimator Due to long-term impact, about 0.2mm of titanium oxide is deposited on the surface. The base material of this spare part is aluminum.

-

Put an appropriate amount of cleaning agent into the barrel, put the parts into the agent, micro bubbles appear after the coating on the surface of the part starts to react, shake the barrel after 6 hours, the coating has begun to fall off, and the agent turns black.

-

After 10 hours, take out the parts and rinse them with clean water, and then use an air gun to blow off the residual coating on the surface. If the thickness of the coating is greater than 0.2mm, it needs to be sandblasted and then soaked. Washing and drying are repeated until the coating is completely removed.

-

Conclusion: SiO2 thin film cleaning agent can be used to remove the coating on the surface of the part, and since the agent itself does not contain acid, the workpiece will not be brittle after cleaning, and the service life will not be affected. If the coating is too thick, it needs to be used in conjunction with physical removal methods .