-

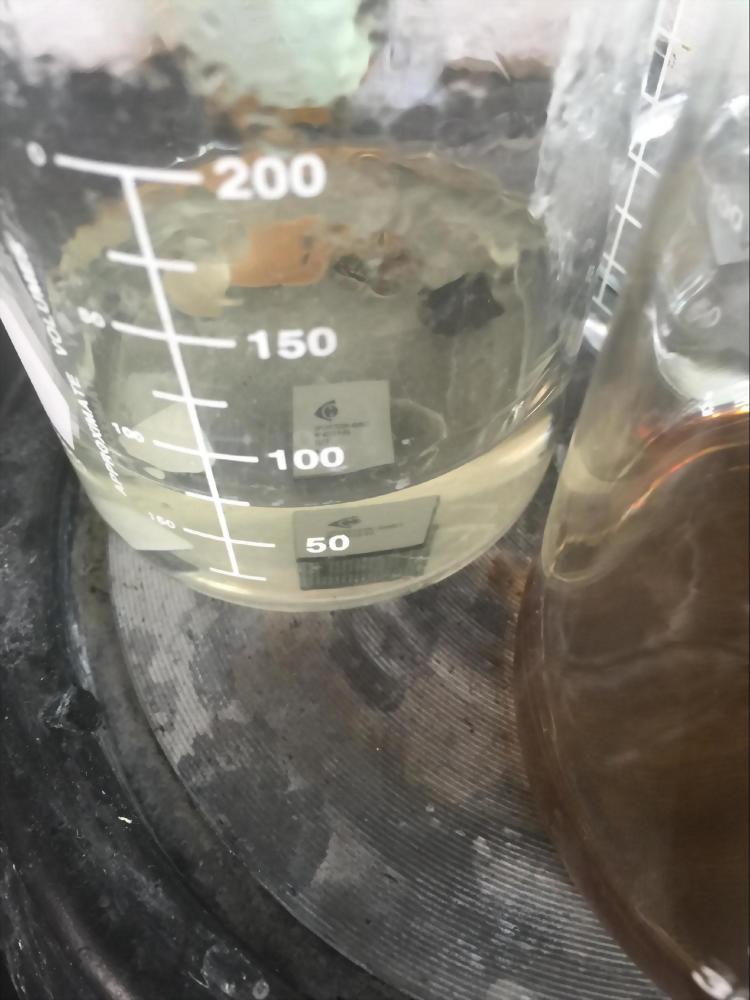

before cleaning

Before the ACF residue is removed.

The purpose of this test is to heat and soak the agent, without wiping or scraping, to effectively remove the residual ACF anisotropic conductive adhesive.

-

Heat the agent to about (70°C), put it into the Driver IC, soak ACHM04-Aplus for 10 minutes, and find that most of the ACF residue has been removed.

-

Increase soaking temperature. Heat the agent to about (100°C), put it into the Driver IC, soak ACHM04-Aplus for 10 minutes, and find that most of the ACF residue has been removed.

-

in conclusion:

ACHM04-Aplus can remove residual ACF anisotropic conductive adhesive.

It is recommended to soak the entire workpiece in a 60~80°C chemical and clean it with ultrasonic vibration.