-

Before washing, look.

-

After the peelable adhesive is torn off, irradiate it with a strong light (full-spectrum halogen lamp) in a clean room, and you can clearly see a circle of residue along the outer edge of the peelable adhesive. There are traces caused by roller indentation in the peelable adhesive attachment area.

-

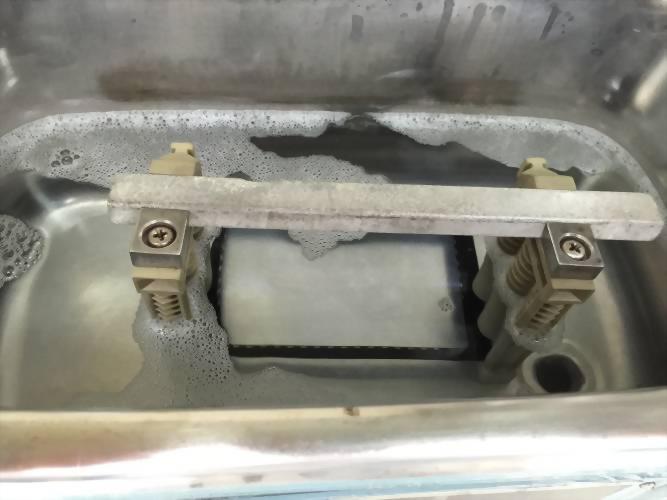

Use ACHM04-A2 peelable glue cleaning agent, at room temperature 32 ℃, after pre-soaking for 5 minutes. Turn on the ultrasonic wave, and clean it for 60 seconds under 40KHz, 50W/L ultrasonic wave. It was found that the residual glue had been removed. But the indentation is still visible.

-

Use PTC06-i3 dust cleaning agent, turn on the ultrasonic wave at a heating temperature of 50°C, and clean it for 240 seconds under 40KHz, 50W/L ultrasonic wave.

-

Clean with PTC06-i3 fine dust cleaner for 240 seconds at a heating temperature of 50°C, 40KHz, 50W/L ultrasonic waves. It was found that most of the residual glue had been removed and the indentation was almost invisible.

-

Replace the agent and repeat the test. Take another panel and peel off the peelable adhesive.

-

Use ACHM04-H2 peelable glue cleaning agent, heat at 50°C, and pre-soak for 10 minutes. Turn on the ultrasonic wave, and clean it for 60 seconds under 40KHz, 50W/L ultrasonic wave.

-

It was found that the peelable glue had been removed.

-

Repeat the test. Reduced temperature test. Use ACHM04-H2 peelable glue cleaning agent, at room temperature 32 ℃, after pre-soaking for 10 minutes. Turn on the ultrasonic wave, and clean it for 60 seconds under 40KHz, 50W/L ultrasonic wave.

before cleaning

after cleaning

But after repeating it several times, it was found that there were still a few panels with a small amount of residual glue that could not be removed.

-

I tested other cleaning agents and found that none of them could be cleaned effectively.

-

Suggestions and discussions:

11.1 ACHM04-A2, and ACHM04-H2 peelable glue cleaning agent are better agents for cleaning the peelable glue residue with automatic cleaning process.

11.2 ACHM04-A2 is strong in cleaning and stripping glue, but care must be taken not to heat it, and not to use ultrasonic waves for too long. Pay attention to time control so as not to cause washing injury due to excessive washing.

11.3 ACHM04-H2 has a weaker cleaning power for removing peelable rubber, but it allows a longer soaking time and is better controlled.

11.4 With PTC06-i3 dust cleaning agent, the cleanliness of the panel can be effectively improved.

11.5 The suggested process is:

1. Tank A, use ACHM04-A2, pre-soak for 5 minutes at room temperature (the room temperature was 32°C during the test).

(ACHM04-H2 can also be used, pre-soaked at a temperature of 50°C for 10 minutes.)

Due to the longer soaking time, the volume of this tank can be increased. If you use ACHM04-A2 agent, you don’t need to heat it, just buy HDPE plastic barrel or stainless steel barrel with enough capacity.

2. For tank B, use ACHM04-A2 peelable glue cleaning agent, and clean it for 60 seconds under 40KHz, 50W/L ultrasonic wave.

(ACHM04-H2 can also be used to clean for 60 seconds at a temperature of 50°C, 40KHz, 50W/L ultrasonic waves.)

3. Tank C, use PTC06-i3 fine dust cleaning agent, heat at 50°C, and clean for 240 seconds under 40KHz, 50W/L ultrasonic waves.

If there are no obvious water marks, indentations or other marks after the peelable glue is removed from the panel, the cleaning time of this tank can be shortened to 60 seconds.

4. Two-fluid waterjet cleaning and air drying.