-

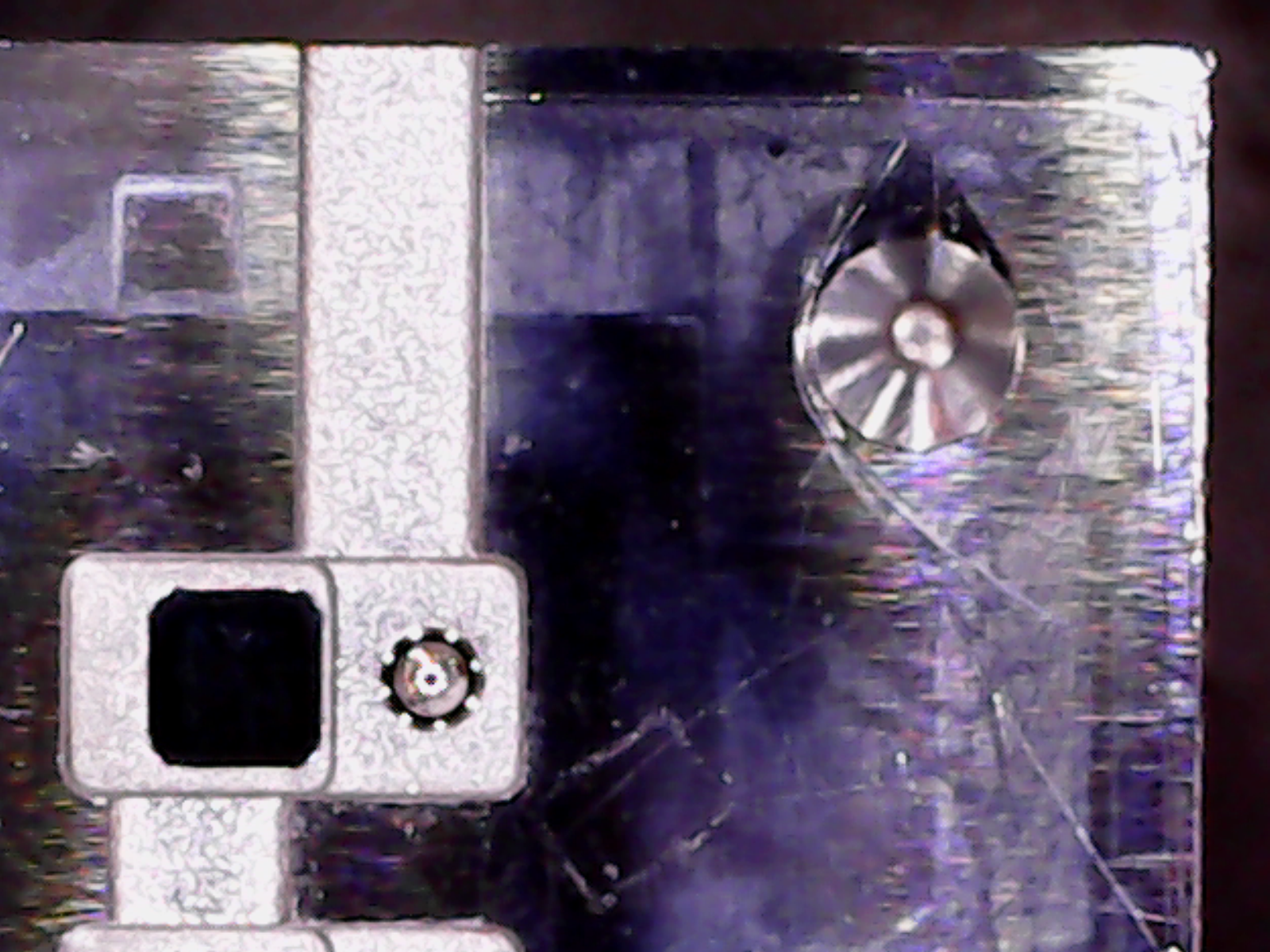

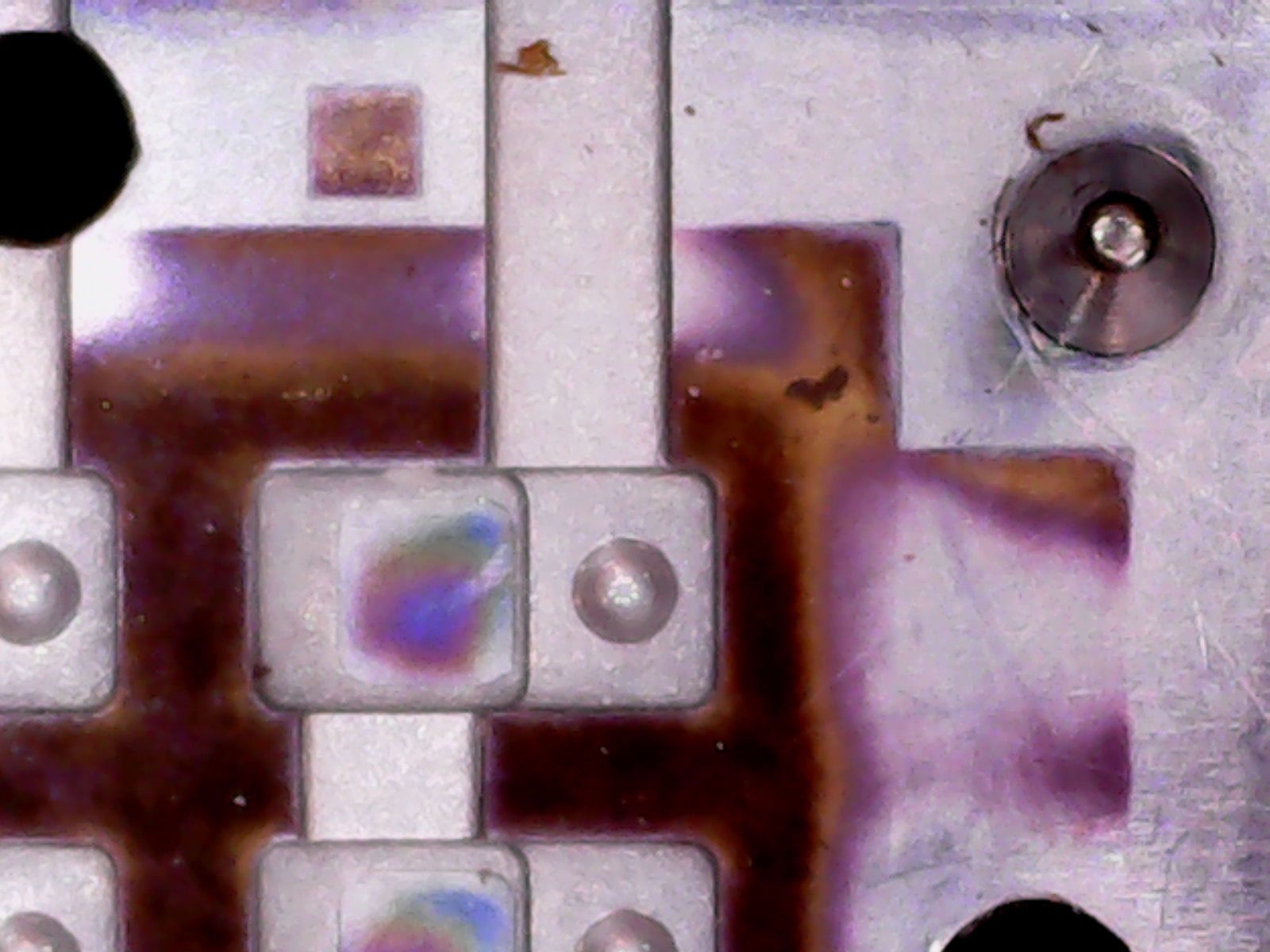

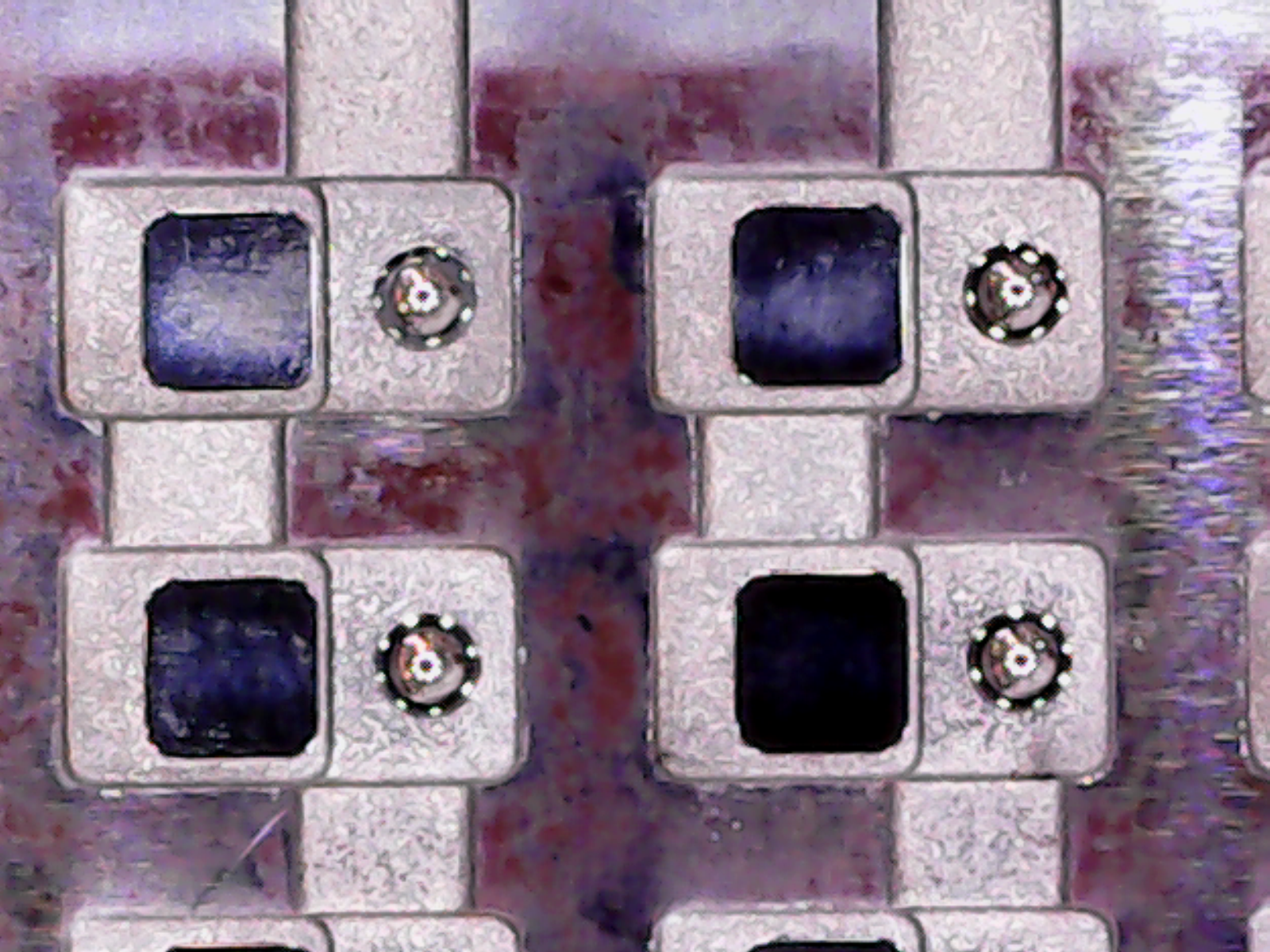

After the LED mold has been used for a period of time, it is very difficult to remove due to the EMC curing at high temperature. Although the residual EMC is continuously removed with rubber cakes, the mold core (at the red arrow in the figure below) is still atomized due to a small amount of residue, resulting in the subsequent injection of LED cups that cannot present a mirror effect. In addition, a large amount of epoxy and release agent remain on the surface of the mold, which is very difficult to remove due to long-term curing at high temperature.

-

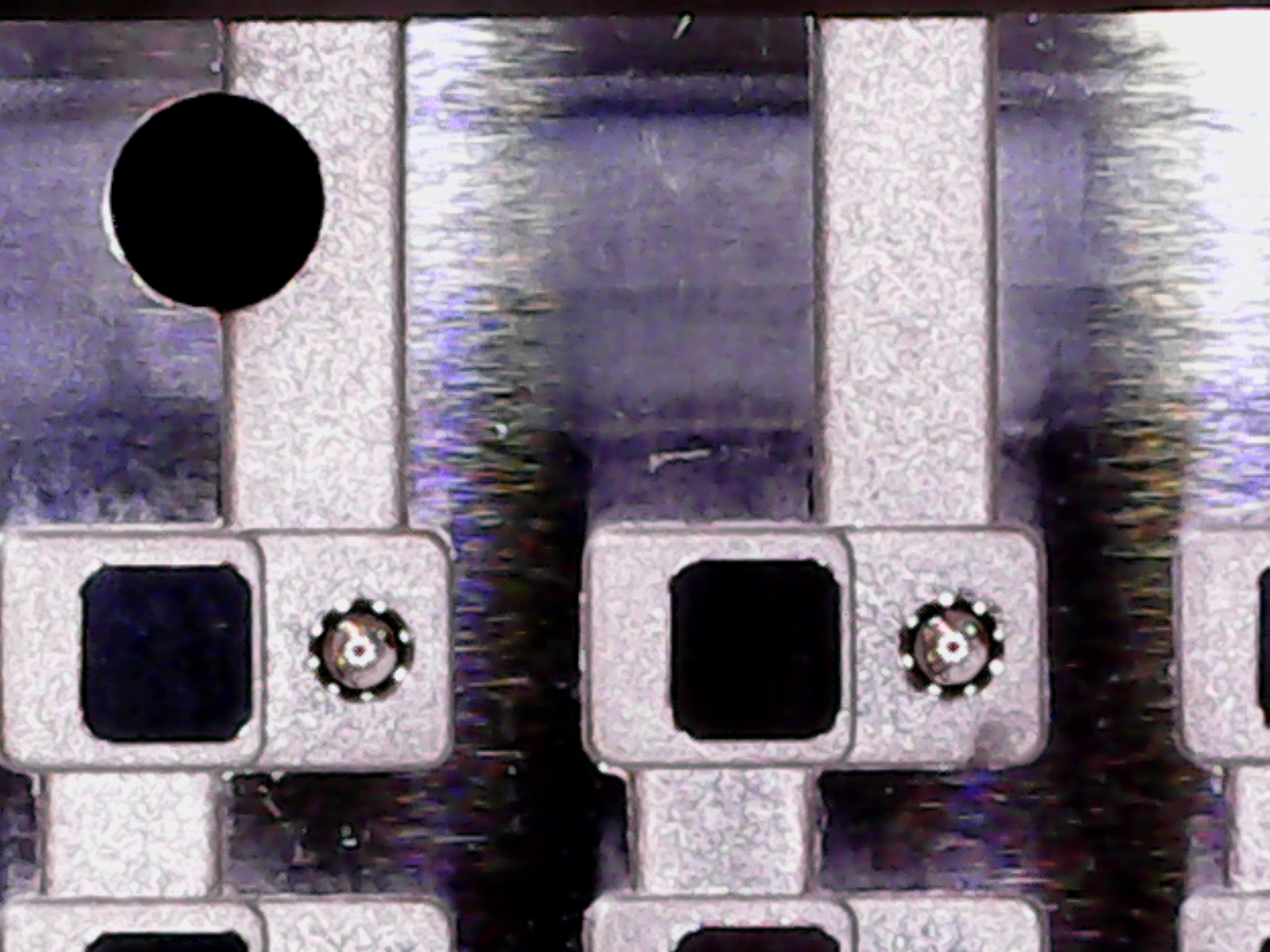

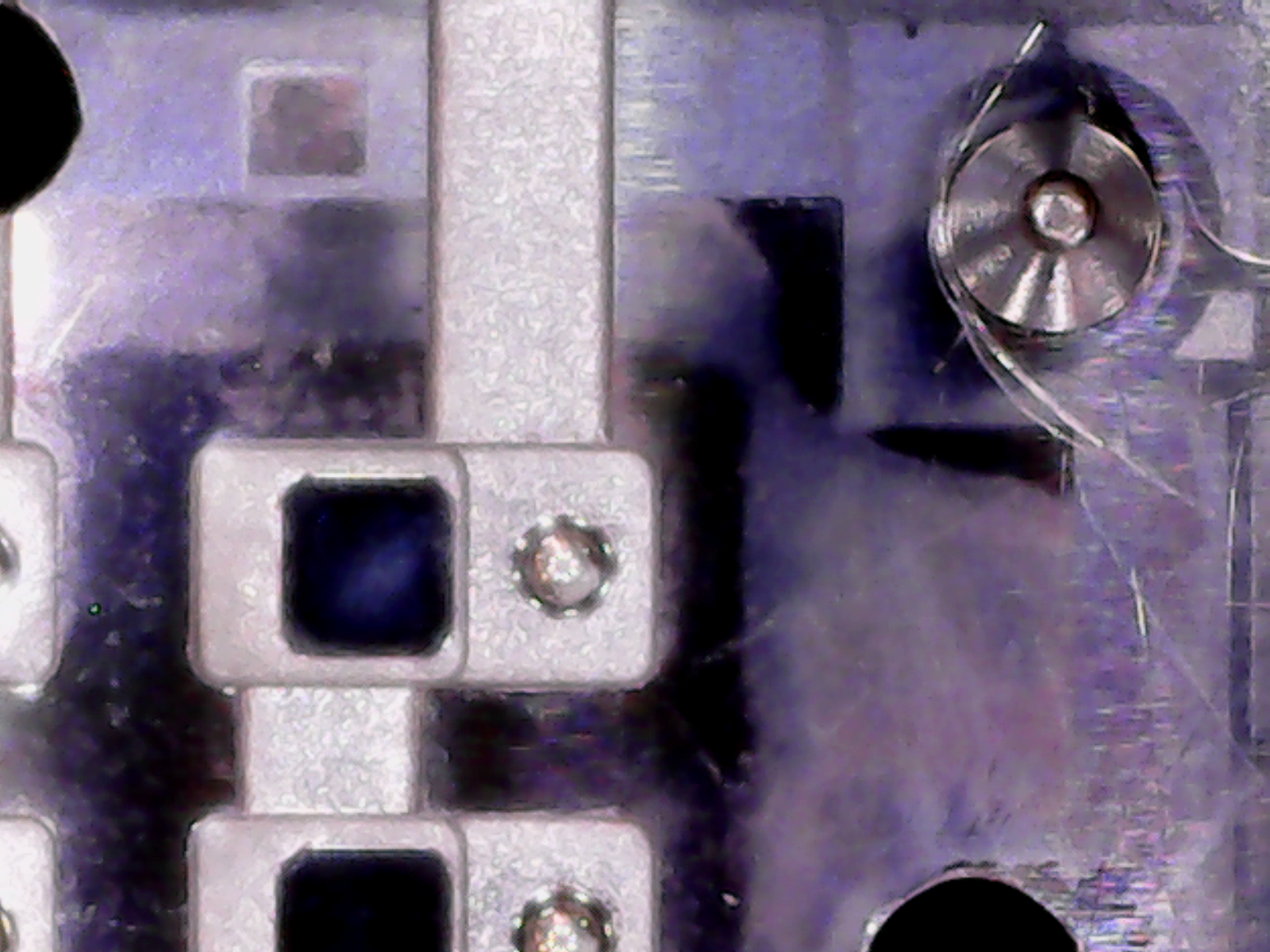

Use hot steel mold cleaner HMC06, 60℃, ultrasonic (40KHz, 50W/L), soak and clean for 10 minutes. The residue was found to have softened slightly and some of the residue had fallen off.

-

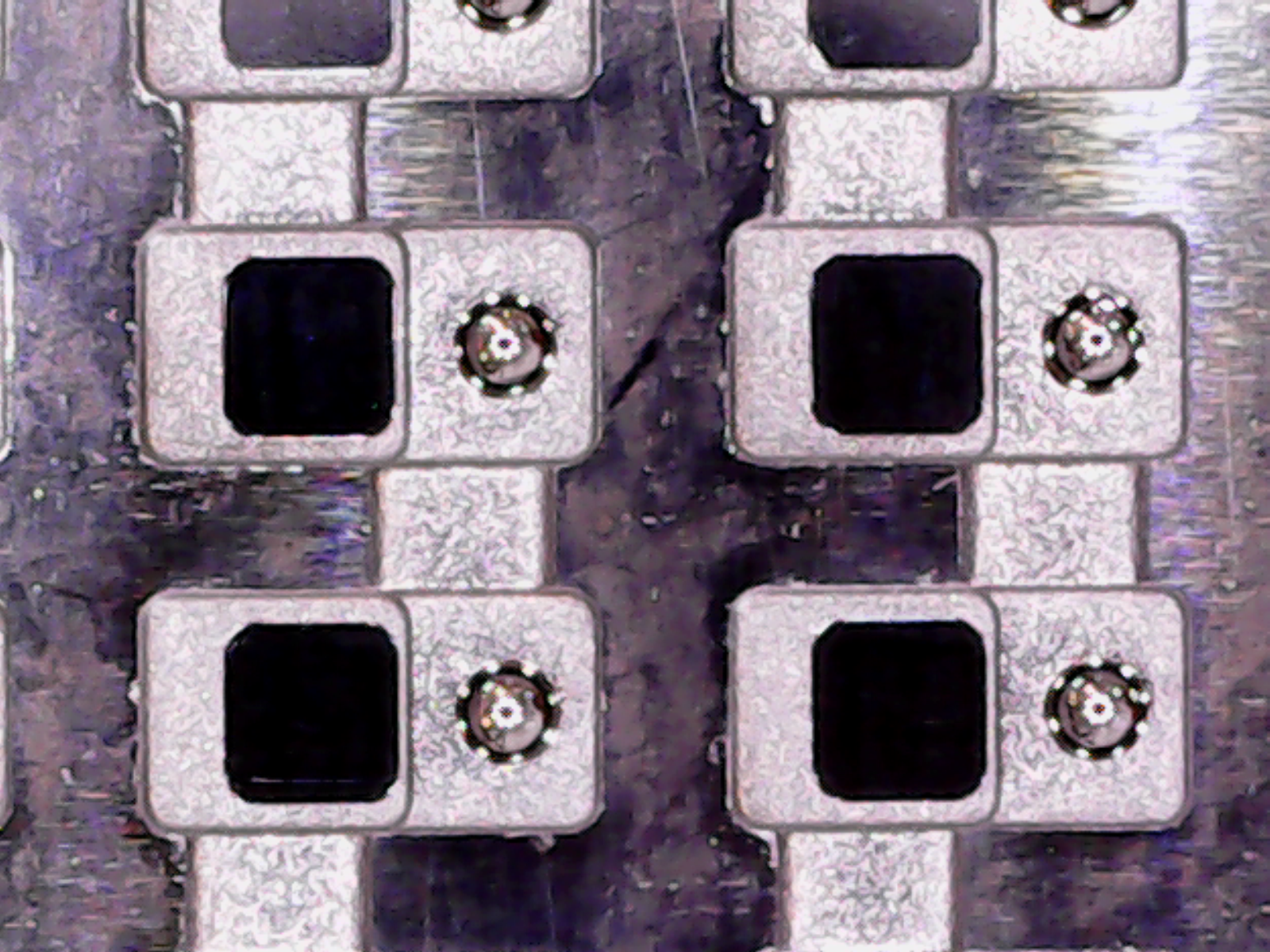

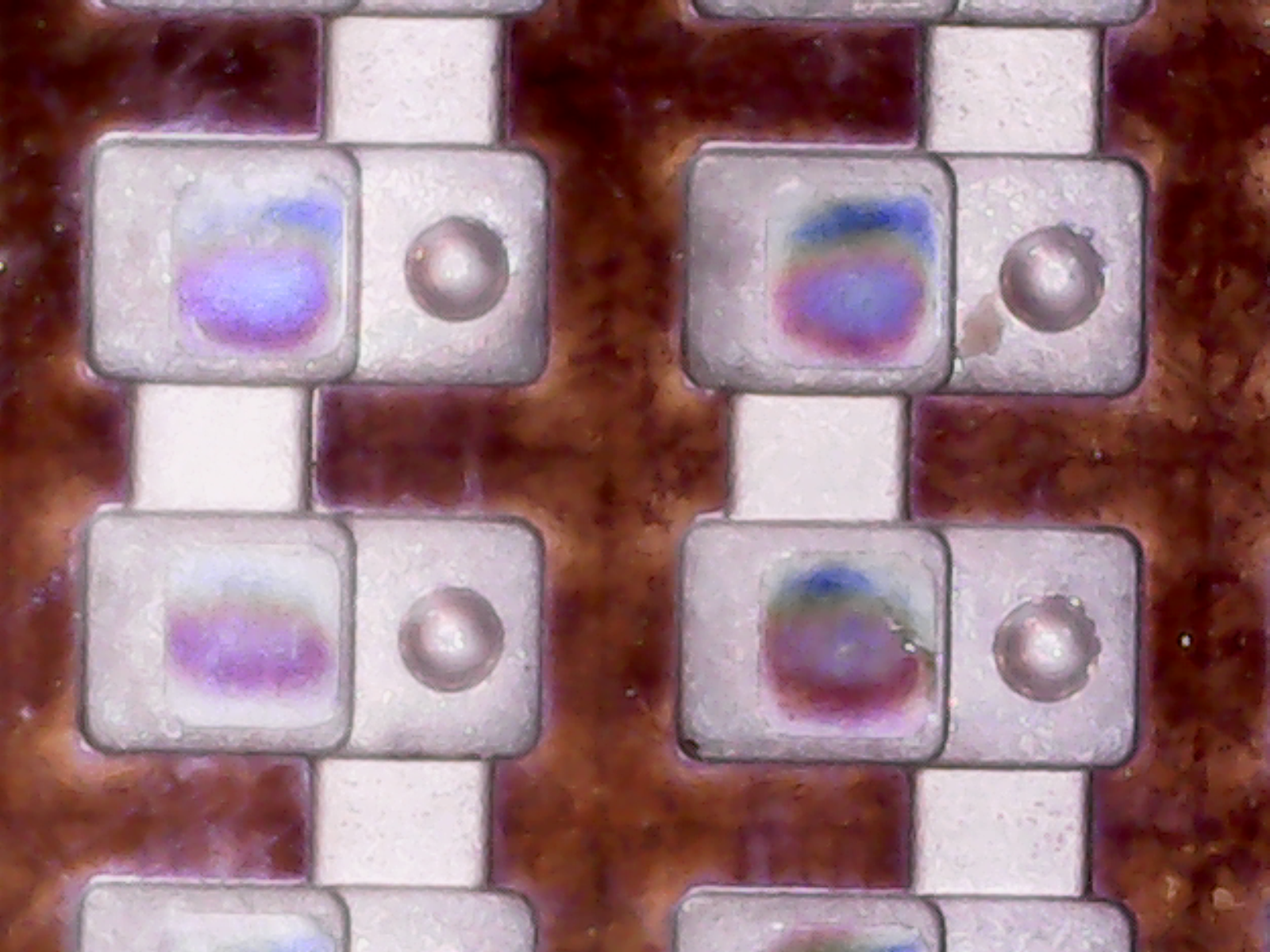

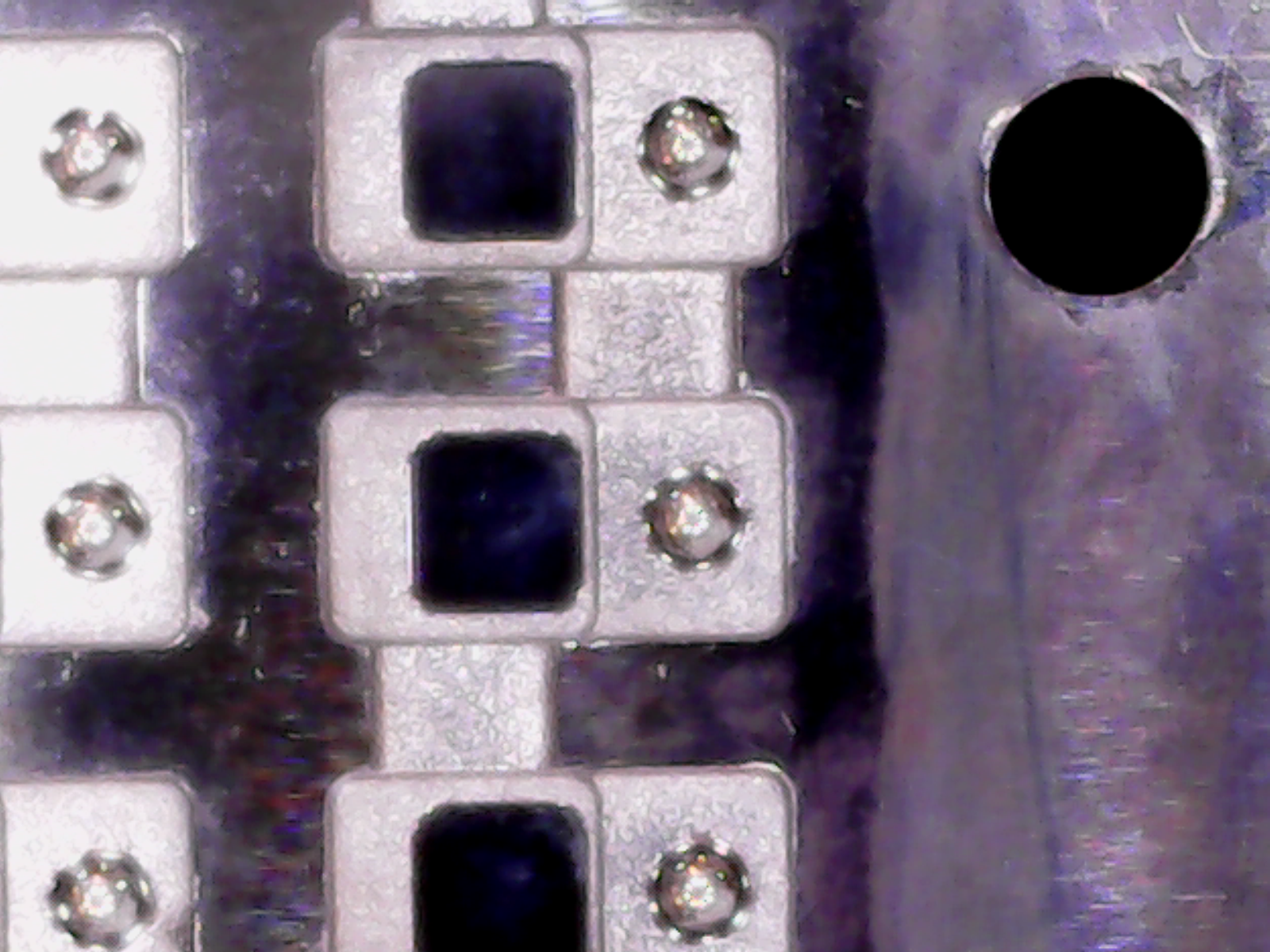

Use hot steel mold cleaner HMC06, 60℃, ultrasonic (40KHz, 50W/L), soak and clean for 20 minutes.

The residue was found to have softened slightly and most of the residue had come off. The most important mold core (at the left arrow in the picture below) has also restored its mirror luster.

-

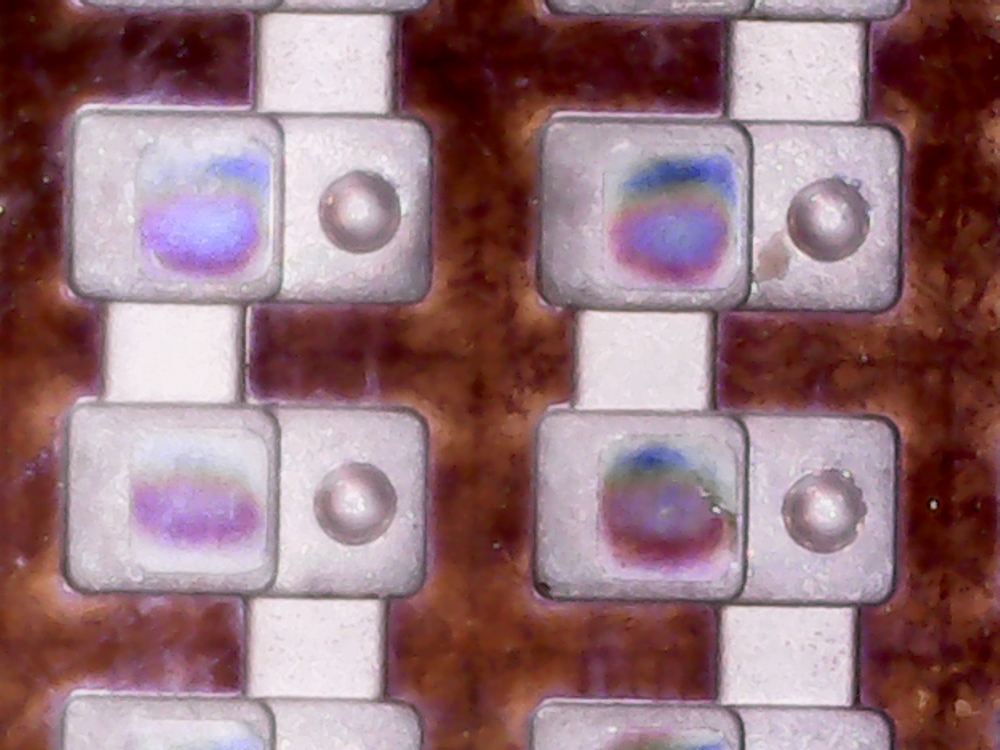

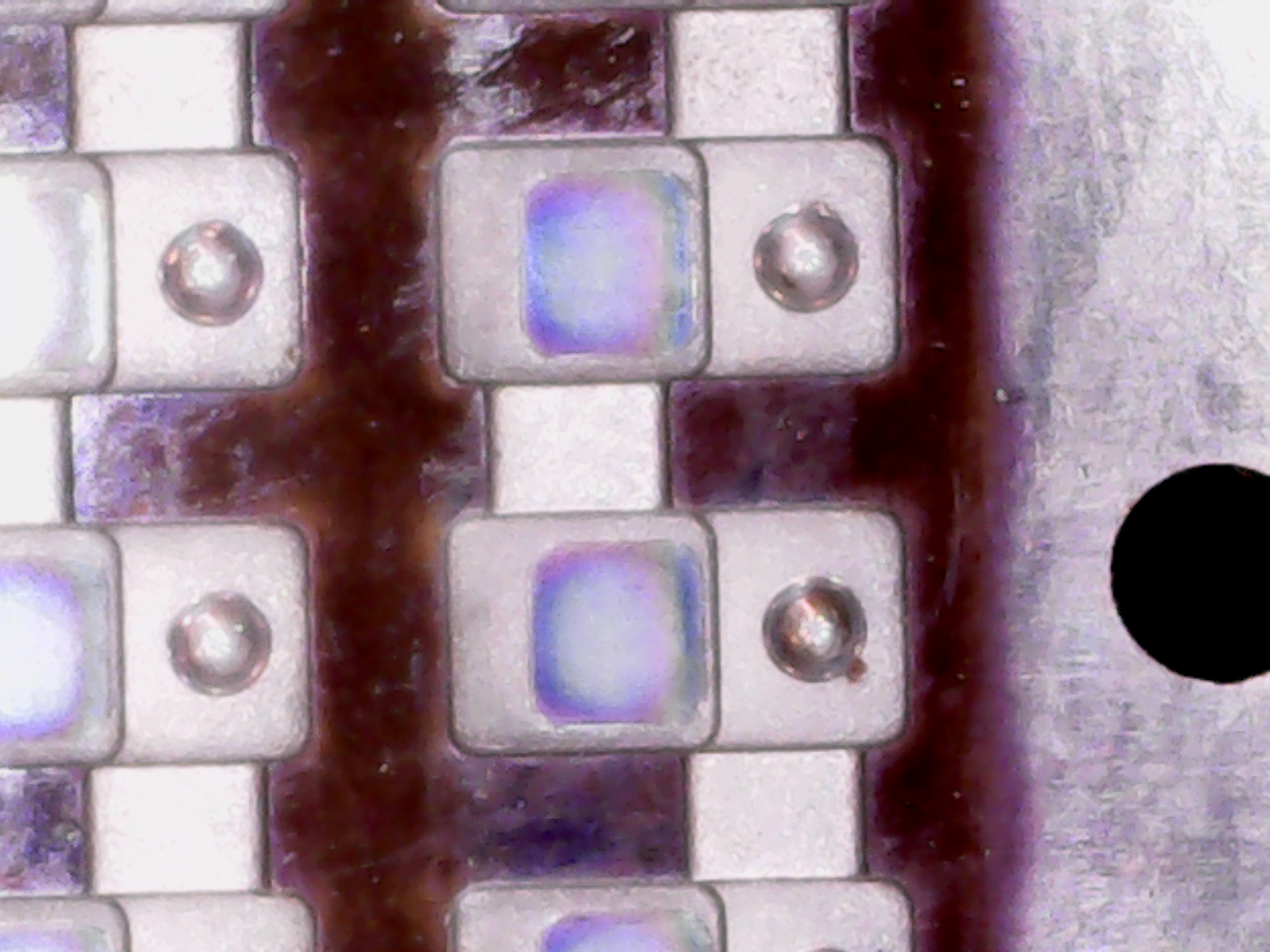

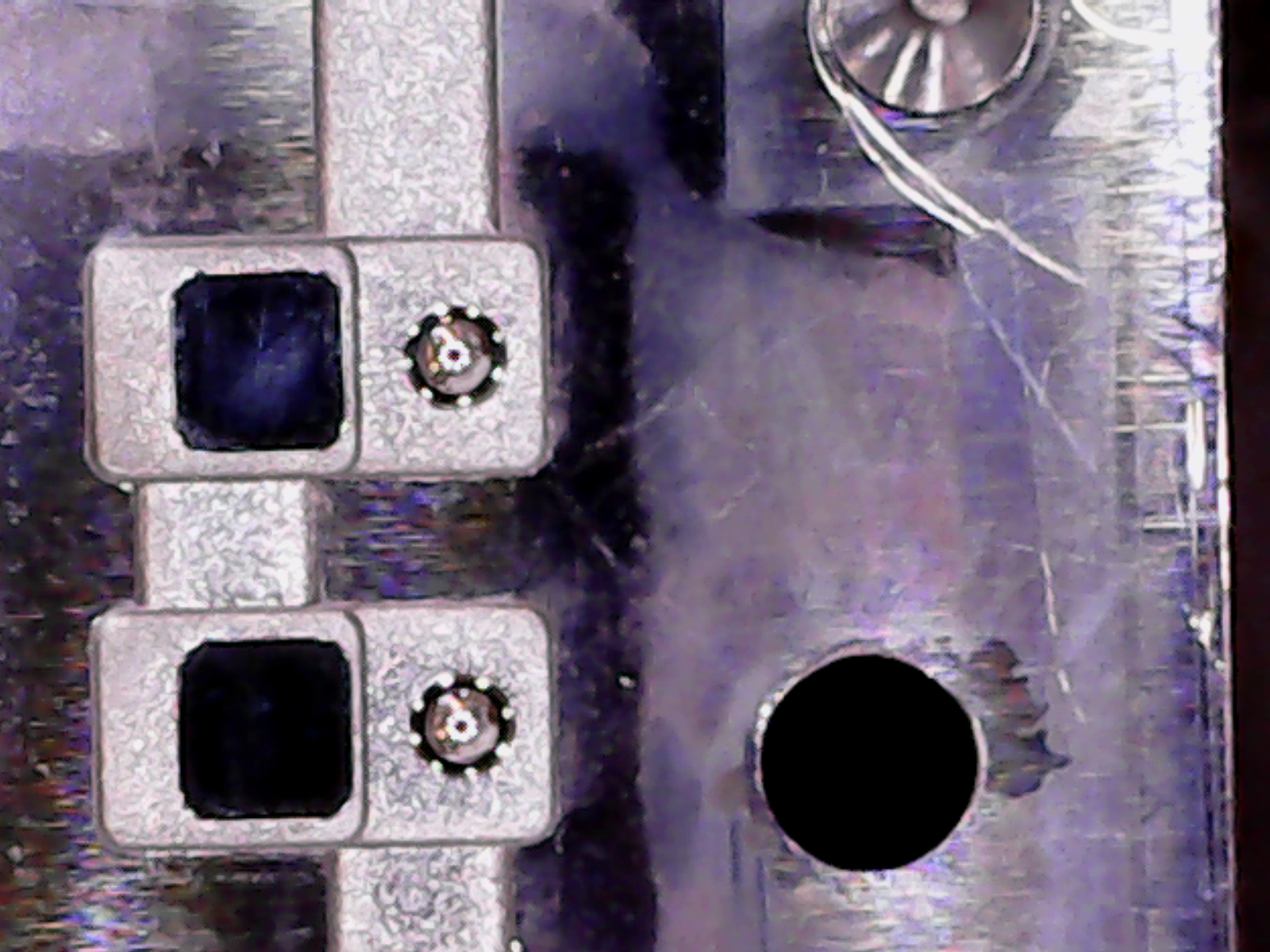

Use hot steel mold cleaner HMC06, 60℃, ultrasonic (40KHz, 50W/L), soak and clean for 20 minutes. Then use a nylon short-bristled brush to remove. It was found that most of the residue had been removed.

-

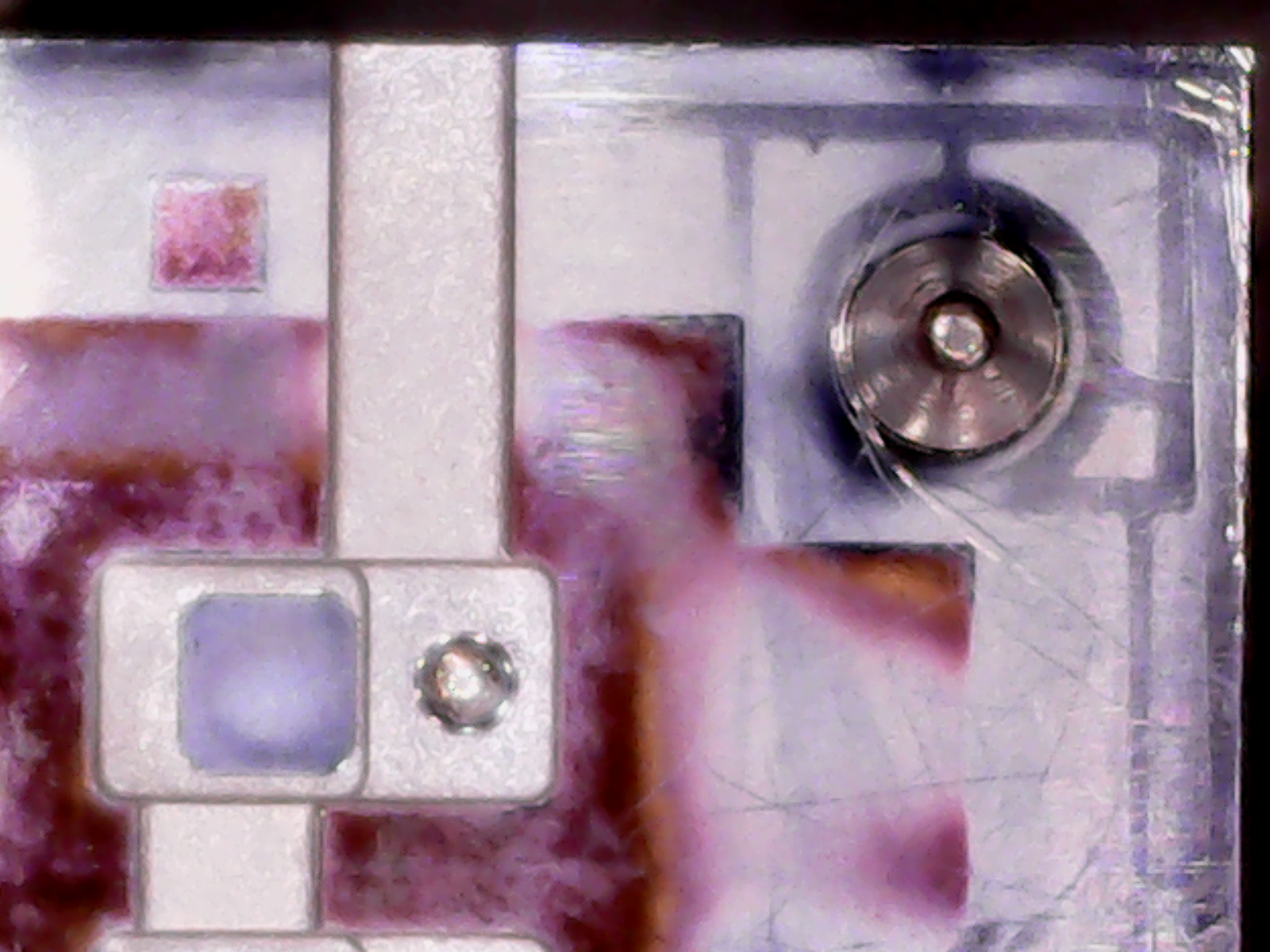

Use hot steel mold cleaner HMC06, 60℃, ultrasonic (40KHz, 50W/L), soak and clean for 30 minutes. Then use a nylon short-bristled brush to remove. It was found that the residue on the mold had been completely removed.