Since the outer frame of the lens has been coated with a layer of hardened ink GT-7, in order not to damage the ink, the weakly alkaline agent PTC06L is used, and the pH value of the stock solution is 11.0+-0.5; when diluted to 5%, the pH value is still maintained at 11.0+ -0.5; It is a chemically stable cleaner.

PTC06L adopts short carbon chain surfactant technology, so compared with OP146 and other lotions, there will be less surfactant residue after rinsing. Due to the long carbon chain number of the surfactant and the greater Van der Waals force, the surfactant is easier to entangle with each other and adhere to the glass. Their comparative characteristics are as follows:

1.1 The foam formed by long carbon chain lotion is not easy to break. PTC06L does not produce foam very much. If foam is formed, it will break in less than 2 seconds.

1.2 When the concentration of long carbon chain detergent is increased (>3%), it is easy to observe "water marks" after cleaning the glass. Regardless of the concentration of PTC06L used (0.1~100%), there will be no "water mark".

1.3 Substantial differences. When the concentration of long carbon chain lotion is increased, the glass will have "water marks". On behalf of the lotion will remain. This is the "essence" of long carbon chain surfactants. When the concentration is lowered, "no residue can be seen" does not mean that there is no residue, but the amount of residue is very small and cannot be seen. But when the client evaporates or coats photoresist, it will show up.

1.4 Restrictions on Use. In order to avoid "water marks", the use of long carbon chain lotion should be limited to a concentration below 3%. This makes it impossible for the long carbon chain lotion to effectively clean the incoming glass when the contamination is serious. PTC06L has no such limitation.

1.5 Difference in drop angle. Since surfactants with long carbon chains are more likely to remain on the glass and have good hydrophilic groups, they will absorb water molecules, making the water drop angle of long carbon chain lotions lower. A lower drop angle does not mean a cleaner wash.

-

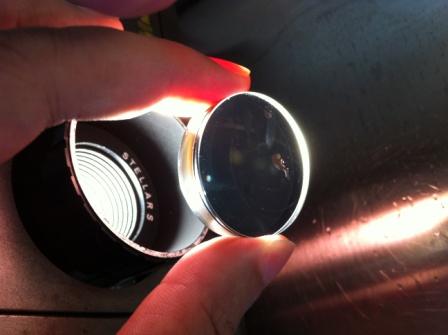

Before washing. The surface of the lens is covered with particles and fingerprints. The lens frame is coated with GT-7 ink.

-

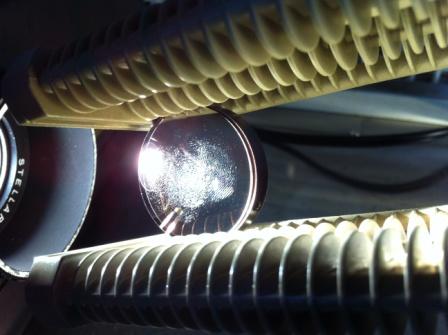

Clean with 3% PTC06L at 40°C, 40KHz, 150W/4L ultrasonic wave for 5 minutes.

-

Take it out and rinse it with clean water. Place it in a dust-free dark room and observe with strong light.

It was found that the particles and fingerprints on it were washed clean. However, the red letter "GT7" written on it is still not washed off. Observing the GT7 ink, there is no discoloration, color fading or peeling off.

Some white spots can still be seen on the cleaned lens, which cannot be scraped off with a PE probe. It is judged not to be a particle, but it should be caused by surface scratches.

-

Repeat the test. Before washing. The surface of the lens is covered with particles and fingerprints.

-

Dip PTC06L with a lint-free cloth, and simulate a single-leaf roller brush machine for wiping. Rinse off with clean water.

It was found that the particles and fingerprints on it were washed clean. The red letter "GT7" written on it has also been washed out. Observing the GT7 ink, there is no discoloration, no color fading or peeling off.

Some white spots can still be seen on the cleaned lens, which cannot be scraped off with a PE probe. It is judged not to be a particle, but it should be caused by surface scratches.

-

Repeat the test. Before washing.

-

Increase the cleaning concentration of the lotion and observe whether GT-7 will cause post-injury. Clean with 6% PTC06L at 40°C, 40KHz, 150W/4L ultrasonic wave for 5 minutes. It was found that the particles and fingerprints on it were washed clean. However, the red letter "GT7" written on it is still not washed off. Observing the GT7 ink, there is no discoloration, color fading or peeling off.

Some white spots can still be seen on the cleaned lens, which cannot be scraped off with a PE probe. It is judged not to be a particle, but it should be caused by surface scratches.

-

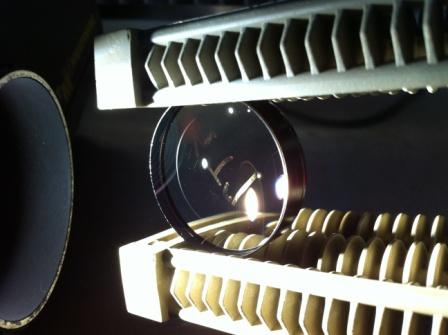

Take another lens, QN2850-06. Please wash before.

-

Clean with 6% PTC06L at 40°C, 40KHz, 150W/4L ultrasonic wave for 5 minutes. It was found that the particles and fingerprints on it were washed clean. Observing the GT7 ink, there is no discoloration, color fading or peeling off.

-

Take another lens, QN2850-03. Please wash before.

-

Clean with 6% PTC06L at 40°C, 40KHz, 150W/4L ultrasonic wave for 5 minutes. It was found that the particles and fingerprints on it were washed clean. Observing the GT7 ink, there is no discoloration, color fading or peeling off.