-

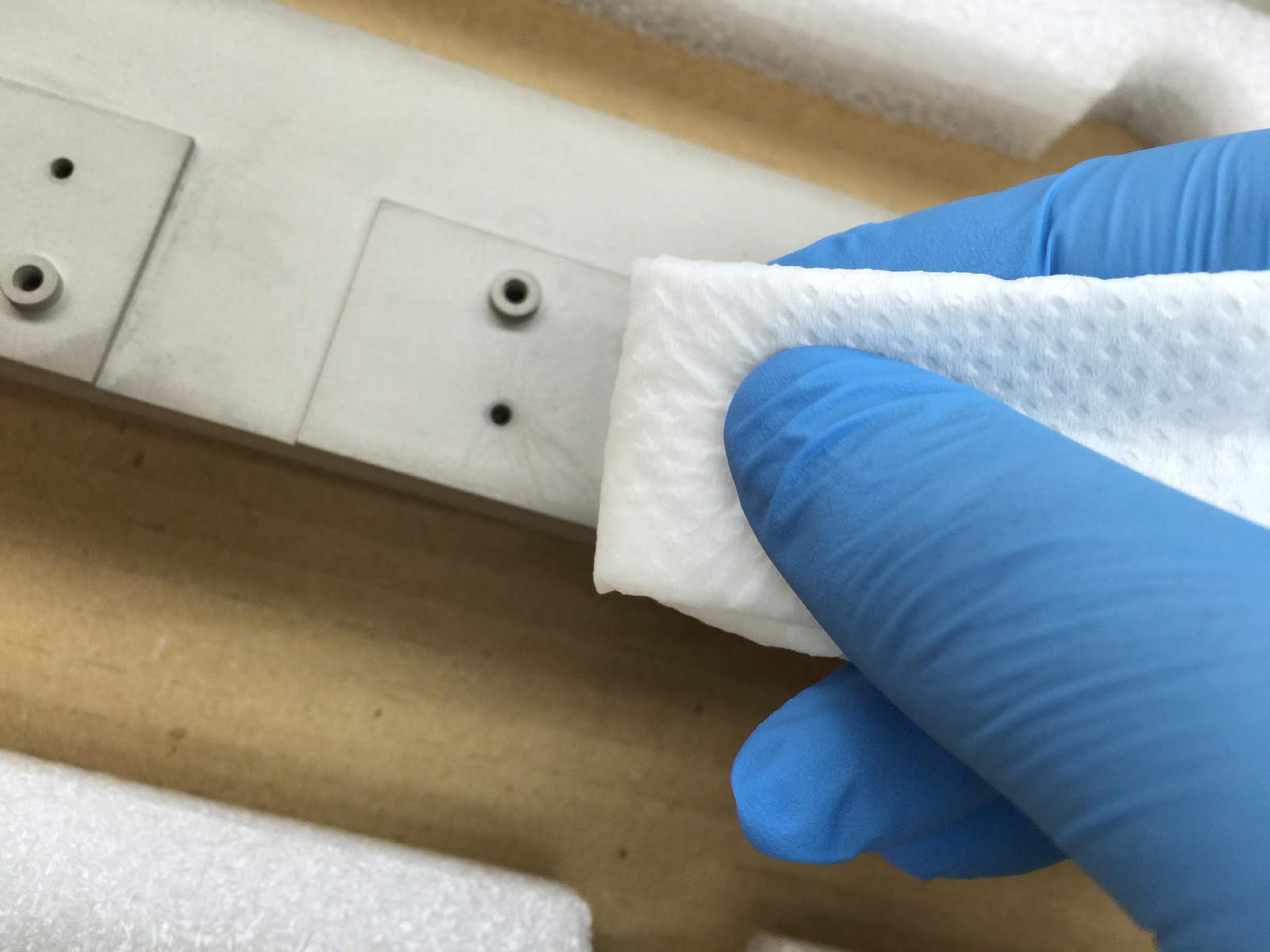

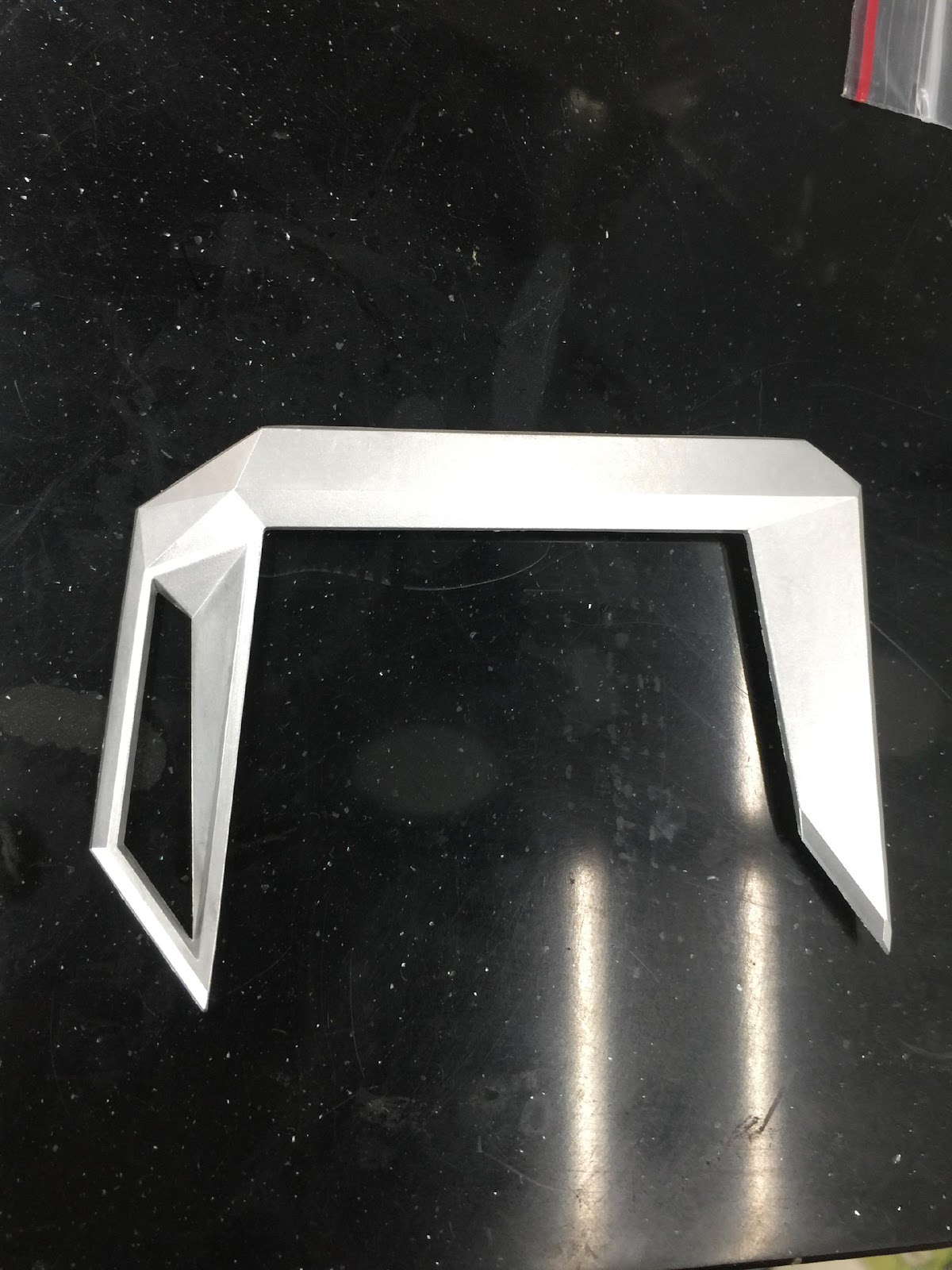

Before cleaning, the scorch marks left by the welding can be clearly seen.

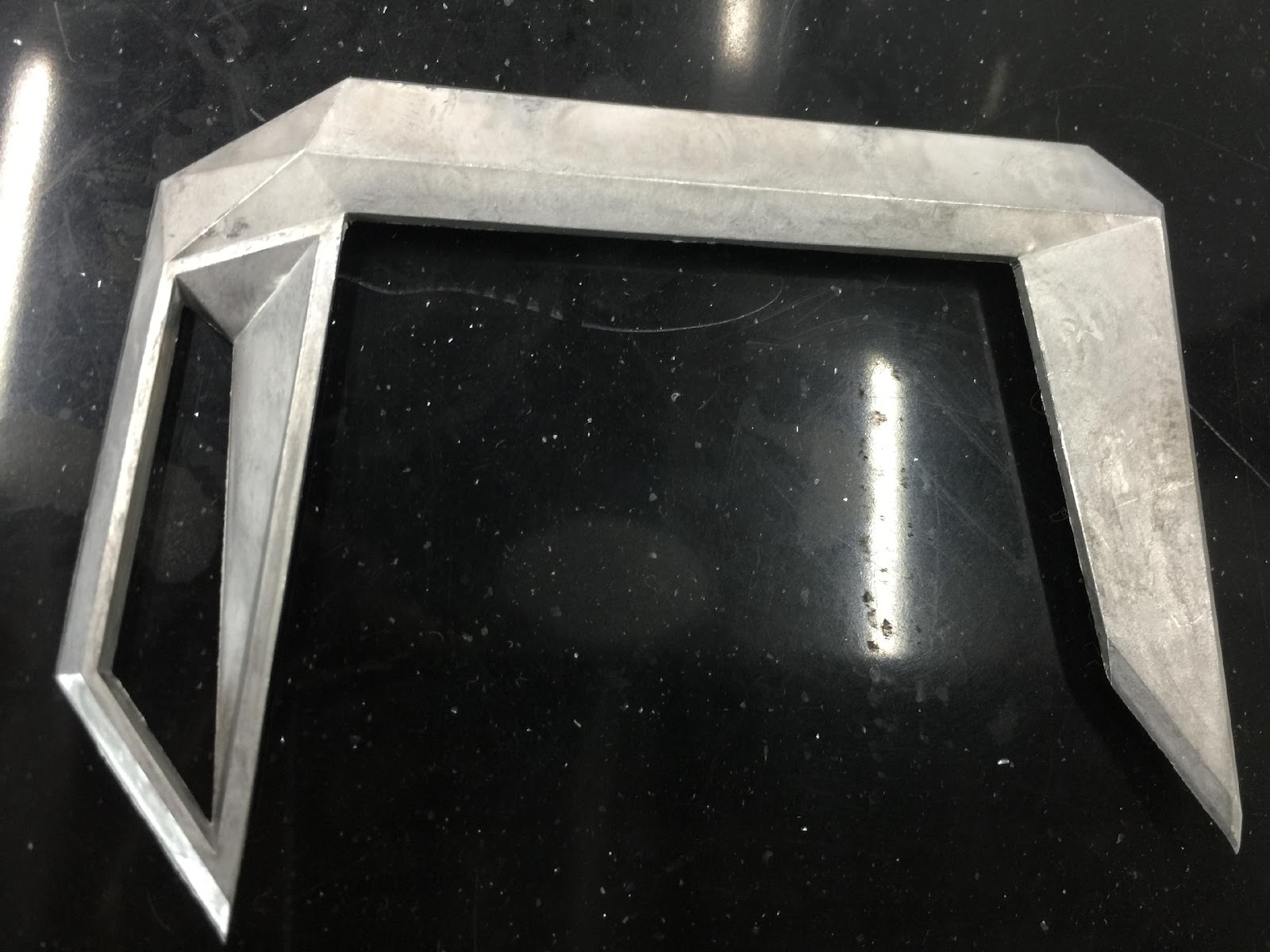

Zoom in to see:

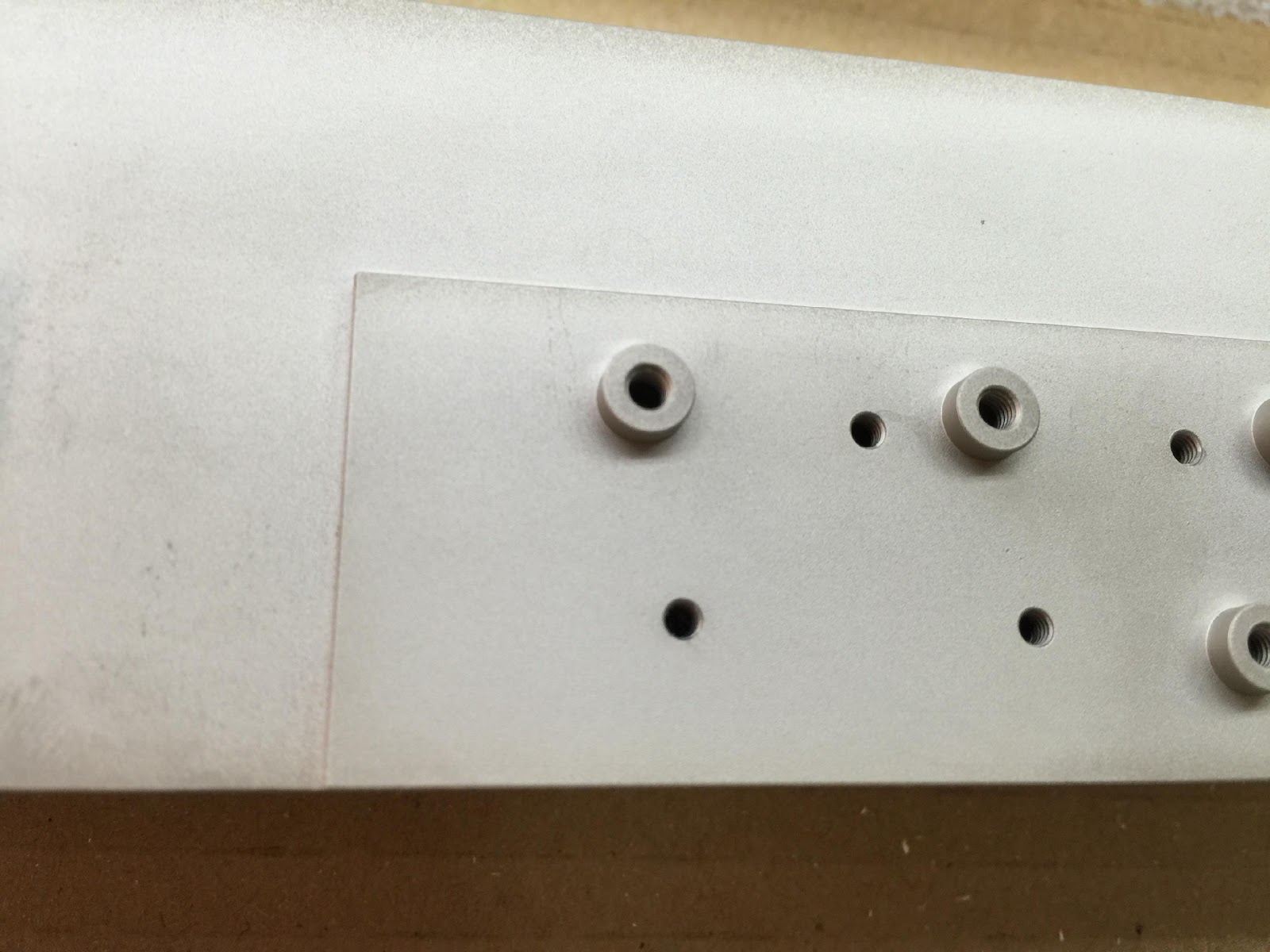

Observe with a microscope:

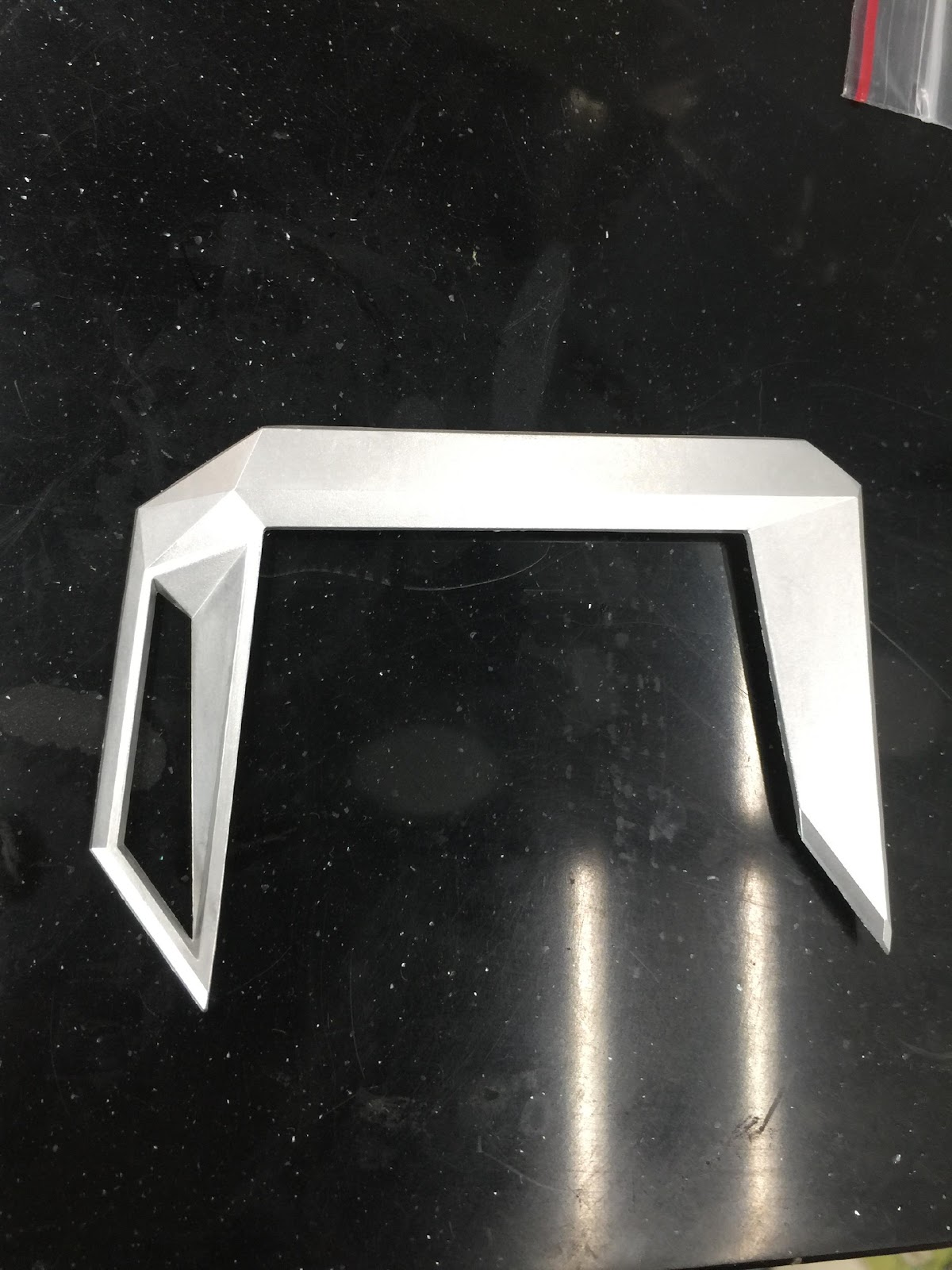

-

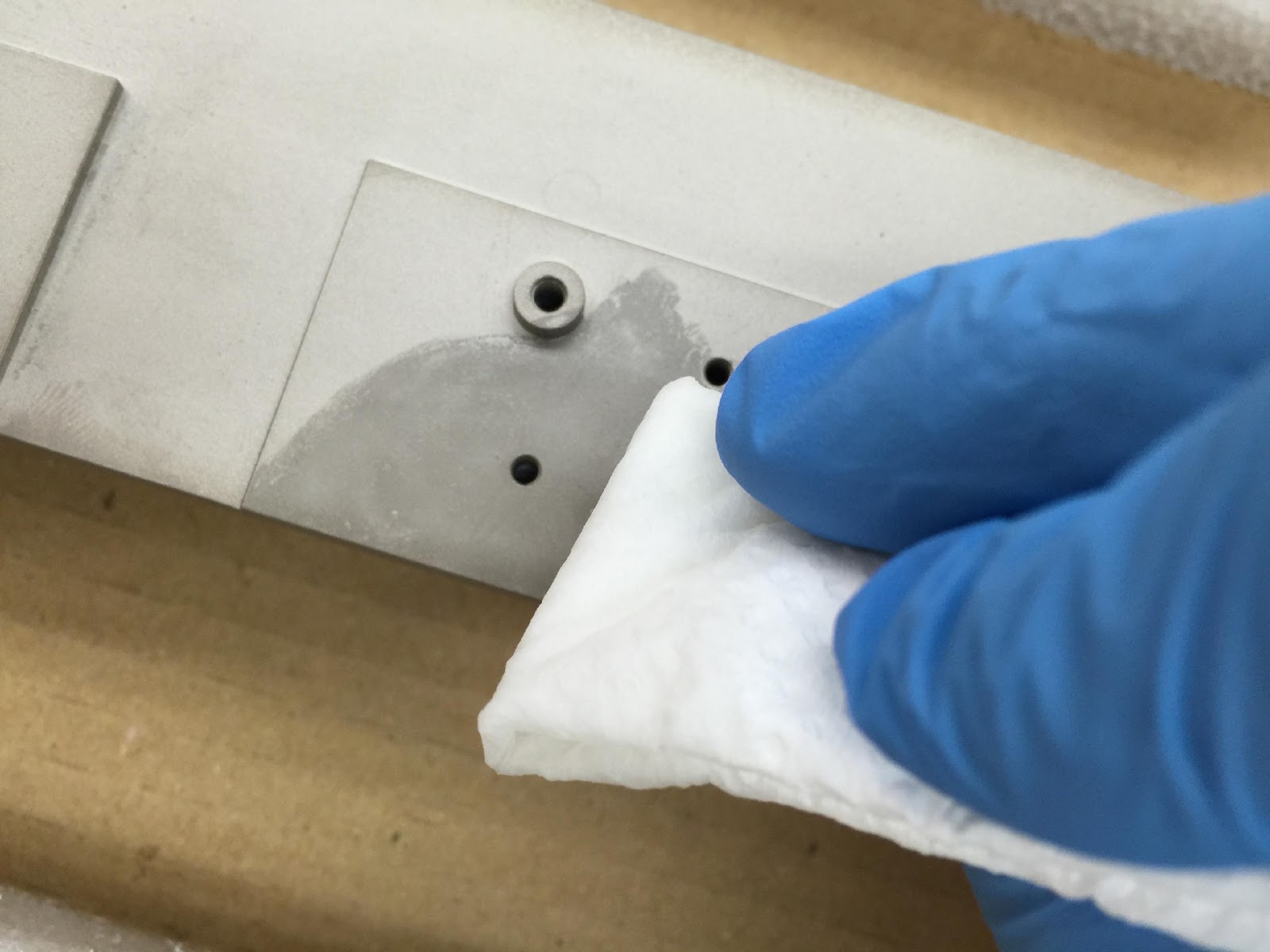

Dip the silicon dioxide film cleaner SMC04 with a red pickle cloth that does not contain emery, and then clean it with water.

Zoom in to see:

Observe with a microscope:

-

Conclusion: The use of silicon dioxide film cleaner SMC04 can effectively remove the scorch marks left after aluminum alloy welding.