-

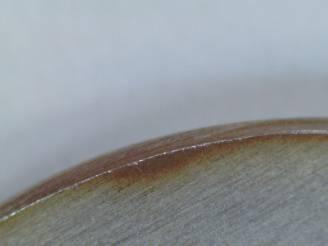

Before cleaning, the scorch marks left by laser cutting.

Zoom in :

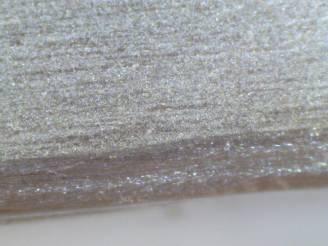

Observe with a microscope:

-

Put into the stainless steel oxide cleaner SMC04.

-

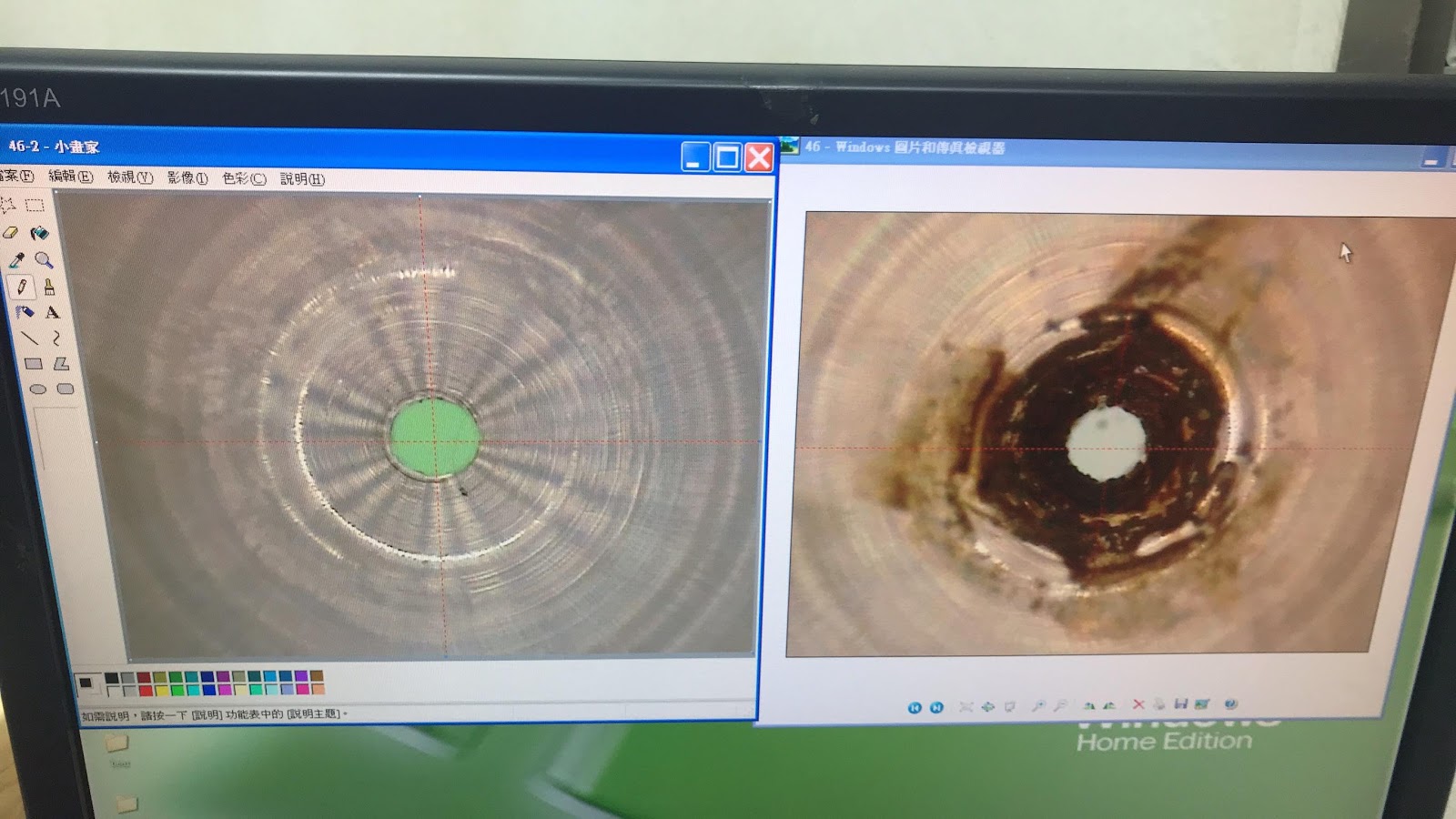

Immersion in stainless steel oxide cleaner SMC04 at 60°C for 30 seconds can effectively remove the scorch marks.

-

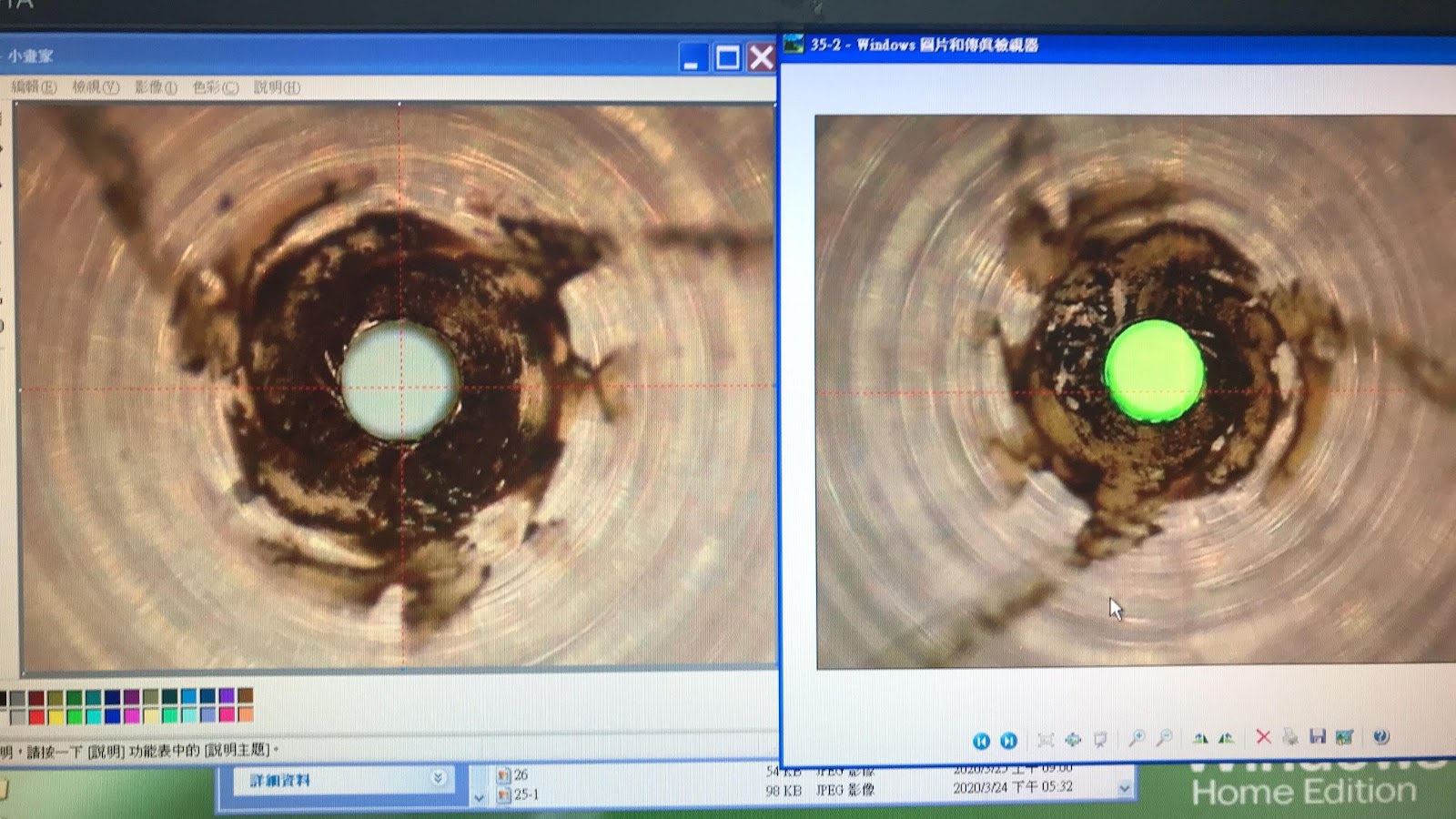

Repeat the test. Soaking in stainless steel oxide cleaner SMC04 at 60°C for 30 seconds can effectively remove the scorch marks. The left side of the photo below is soaked SMC04, 60 ℃, 30 seconds; the right side is not soaked.

-

conclusion:

5.1 Soak in stainless steel oxide cleaner SMC04 at 60°C for 30 seconds, which can effectively remove the scorch marks left by laser cutting.